Automated glass processing

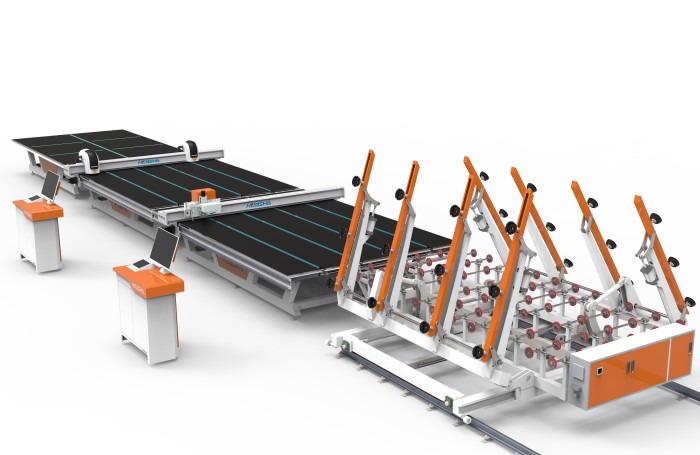

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has four grand arms

6. Max glass size:4200*2800mm

- Product Description

Automated Glass Processing Solutions for Global Large-Scale Projects

In the fast-paced world of glass manufacturing, automated glass processing systems have become indispensable for industries demanding speed, accuracy, and scalability. At Shandong Huashil Automation Technology, we engineer cutting-edge solutions that streamline production while maintaining rigorous quality standards. Whether you’re producing solar panels, automotive windshields, or architectural facades, our vertically integrated systems ensure seamless operations from raw material to finished product.

Why Choose Our Automated Glass Processing Equipment?

✅ End-to-End Control

From in-house R&D to final assembly, every component is designed for durability and precision. Our proprietary laser calibration technology achieves tolerances as tight as ±0.005mm, ideal for ultrathin display glass or EV battery panels.

✅ Customization Ready

Need to handle curved partitions or jumbo-sized panels? Our modular designs adapt to thickness changes in 15 minutes, with OEM/ODM support for unique functional requirements.

✅ Global Compliance

Pre-certified to meet EU Machinery Directive, OSHA, and IATF 16949 standards, our automated glass processing equipment accelerates your market entry without compliance headaches.

✅ 24/7 Lifeline Support

A dedicated technical team resolves 90% of issues remotely within 4 hours, minimizing downtime risks.

Technical Specifications: HSL-LSX4228 Model

- Three-Table Design: Loading, cutting, and breaking stations optimize workflow.

- Max Glass Size: 4200x2800mm (customizable up to 6000x3200mm).

- Precision Metrics: ±0.1mm cutting accuracy, 500–1200 panels/day output.

- Software: Optima® optimization suite for material waste reduction.

- Energy Efficiency: 30% lower power consumption vs. industry benchmarks.

Where Our Systems Excel

🏙️ High-Rise Building Facades

Process jumbo laminated panels (up to 25mm thickness) with anti-scratch coating compatibility.

🚗 Automotive Glass Processing

Achieve defect rates below 0.1% for windshields, sunroofs, and EV battery covers.

☀️ Solar Panel Manufacturing

Handle tempered low-iron glass with vacuum suction systems to prevent micro-cracks.

🏭 Industrial Partitions

Quickly reconfigure settings for curved or frosted glass designs.

Built for Your Bottom Line

1. Cost Control: Vertical integration cuts middlemen costs, offering prices 15–20% below competitors.

2. Agile Delivery: 45-day standard lead time, 30% faster than industry averages.

3. Lifetime ROI: IoT-enabled predictive maintenance slashes repair costs by 40%.

Global Support, Local Speed

- Regional warehouses in Asia, Europe, and North America ensure spare parts arrive within 72 hours.

- Multilingual project managers streamline communication across time zones.

Frequently Asked Questions

Q: How do you ensure precision in the product for delicate materials like ultrathin display glass?

A: Our AI-driven vision systems adjust cutting parameters in real-time, while vibration-dampening rails maintain micron-level accuracy.

Q: Can your machines integrate with existing tempering furnaces or laminating lines?

A: Yes! We provide compatibility audits and interface customization to minimize retrofitting costs.

Q: What certifications do your systems hold?

A: All equipment meets CE, ISO 9001, and UL standards. Automotive-grade models comply with IATF 16949.

Q: What's included in your after-sales support?

A: Free remote diagnostics, on-site training, and 12-month warranties on critical components.

Ready to Transform Your Production Line?

Schedule a Live automated glass processing Demo

See how our HSL-LSX4228 system can slash your material waste and boost output.

📧 contact us Today: salescathy@sdhuashil.com

⏱️ Response Time: Within 2 business hours.

Shandong Huashil Automation Technology Co., Ltd — Where Innovation Meets Industrial Precision.