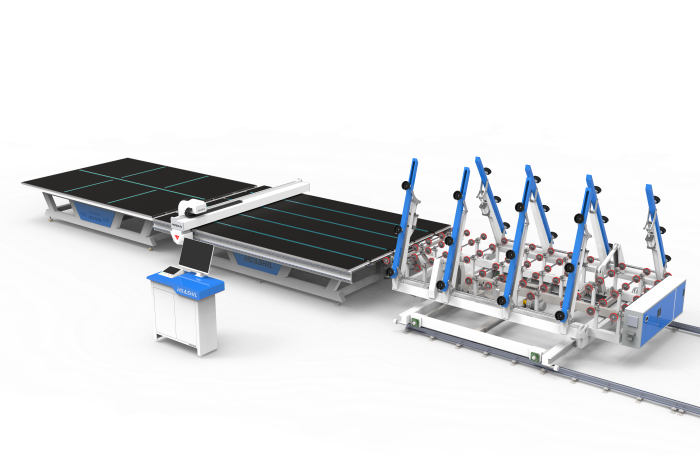

Float glass double machinery

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has four grand arms

6. Max glass size:4200*2800mm

- Product Description

Float Glass Double Machinery – High-Efficiency, Customized Solutions for Global Manufacturers

Looking for a reliable, automated solution to boost your glass production efficiency? Our float glass double machinery combines precision engineering with cutting-edge automation, designed to meet the demands of high-volume manufacturers. Stable quality control, reduced operating costs, and smooth adaptation to your individual production demands are all features of this system, which is built for durability and energy efficiency. Our gear provides unparalleled performance and round-the-clock technical assistance, making it ideal for producing architectural glass, automotive components, and solar panels.

Why Choose Our Float Glass Double Machinery?

- AI-Driven Precision: Achieve cutting accuracy within ±0.2mm, minimizing material waste.

- Modular Design: Scale production capacity with plug-and-play upgrades.

- Energy Efficiency: Reduce power consumption by up to 30% compared to conventional systems.

- Global Compliance: CE, ISO, and OSHA-certified components ensure hassle-free imports.

- 24/7 Support: Rapid troubleshooting and spare parts delivery worldwide.

Technical Specifications

| Parameter | Specification | |

|---|---|---|

| Model | HSL-LSX4228 | |

| Max Glass Size | 4200*2800mm | |

| Stations | 2+2 (configurable) | |

| Automation Software | Optima™ Process Optimization Suite | |

| Rail Type | Above/Underground | |

| Arms per Side | 4 Grand Arms |

Applications Across Industries

Our float glass double machinery is engineered for versatility:

1. Architectural Glass: Produce large-format, tempered panels for facades and interiors.

2. Automotive Glass: Cut and shape windshields, sunroofs, and side windows with precision.

3. Solar Panels: Process thin-glass solar modules with zero edge defects.

4. Decorative Glass: Create custom designs for furniture and interior décor.

Why Partner With Us?

1. Direct Factory Pricing

We use premium components like Siemens PLCs and SKF bearings, eliminating middlemen to offer competitive rates.

2. Tailored Solutions

Our R&D team adapts machinery to your facility layout, glass thickness (2–25mm), and automation goals.

3. Worldwide Service Network

Get on-site installation support and <24-hour remote assistance across time zones.

FAQ

1. How do you ensure quality in high-volume production?

Our machinery integrates AI-powered sensors to monitor cutting pressure and alignment in real time, backed by ISO 9001-certified assembly processes.

2. Can the system handle ultra-thin or coated glass?

Yes! Customizable grippers and speed settings accommodate glass as thin as 1.6mm or coated variants.

3. What's included in after-sales support?

We provide technical training, a 2-year warranty, and lifetime access to spare parts inventories in 15 countries.

4. What's the lead time for overseas orders?

Most shipments depart within 4–6 weeks, with door-to-door logistics handled by our partnered freight forwarders.

5. How do you reduce long-term maintenance costs?

Durable stainless-steel components and self-lubricating rails ensure ≤1% downtime over 10+ years.

Ready to Upgrade Your Production Line?

[Request a Custom Quote] – Let's tailor float glass double machinery to your needs!

📧 contact us: Huashil.com">salescathy@sdhuashil.com

🌐 Trusted By: Manufacturers in 30+ countries, with 100+ installations since 2012.