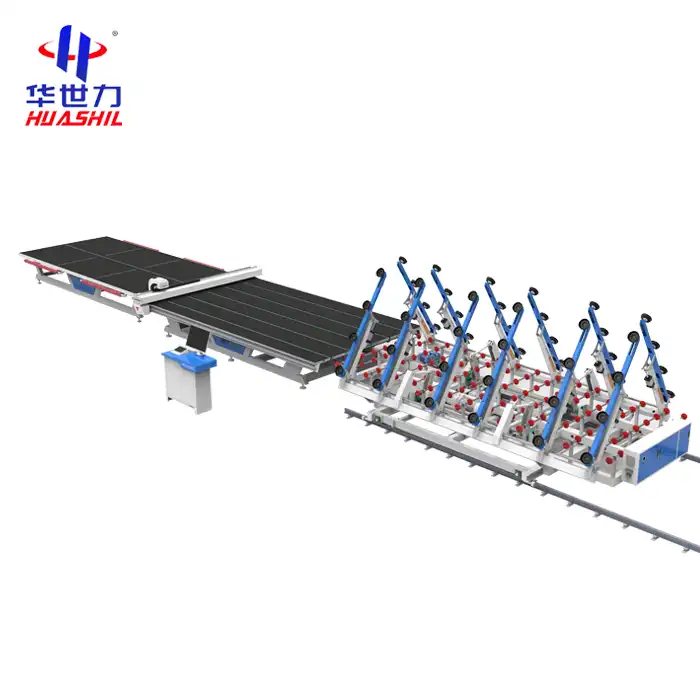

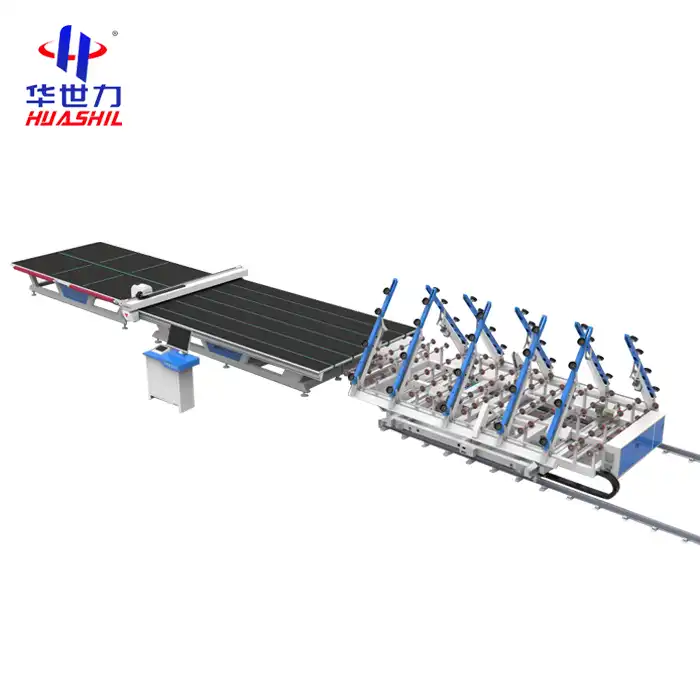

Glass cutting assembly line

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has three grand arms

6. Max glass size:3660*2800mm

- Product Description

Glass Cutting Assembly Line: HSL-LSX3829 by Huashil Machine

Huashil Machine is a leading manufacturer and supplier of high-quality products. Our HSL-LSX3829 glass cutting assembly line offers industry-leading precision, efficiency and automation to meet the demanding needs of glass processing companies worldwide. With over 10 years of export experience and a professional R&D team, Huashil provides reliable, cost-effective solutions backed by excellent after-sales support.

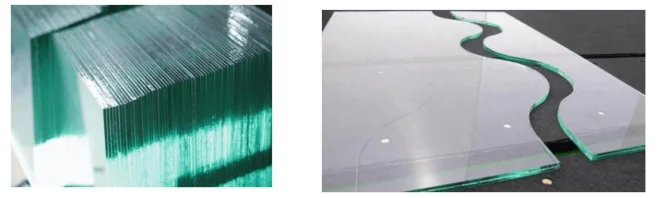

Cutting finished product type:

Functions & Features:

1.Cutting technology and automatic oil supply:

A:Professional glass cutting control system realizes automatic cutting of straight and special-shaped glass, greatly improving glass cutting efficiency.

B:The pressure of the cutting head is controlled by an electromechanical precision pressure valve. The uniform output pressure of the cylinder allows the cutting head to perfectly fit the glass surface for cutting, thus avoiding the cutting phenomenon caused by glass quality problems .

C:When cutting glass, the cutting oil is automatically filled using pneumatic pressure control, and moves synchronously with the cutting head through the PLC control system .

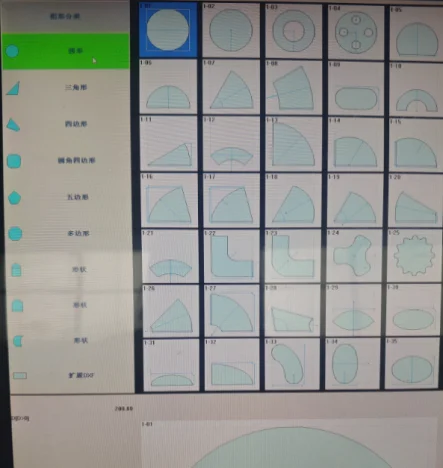

2.Optimization software and special-shaped libraries:

Compatible with the standard G code of Italian OPTIMA optimization software and domestic Guiyou software: achieving versatility in processing files in different formats.

3.Automatic edge positioning and intelligent special-shaped scanning:

Automatic edge-finding and positioning of glass: Accurately detects the actual position and deflection angle of the glass, and automatically adjusts the cutting path of the cutter head to improve efficiency.

4.Telescopic boom and automatic loading:

Equipped with 3 big arms, each big arm is equipped with 4 sets of NBR suction cups to absorb glass, ensuring the stability and reliability of loading large glass sheets.

5.Air floating countertop:

Cutting table and breaking table are equipped with air holes, and centrifugal fans provide high-pressure airflow to facilitate the transportation or shifting of glass while preventing scratches on the table.

6.Glass conveying:

After glass cutting, glass is transported to the air flotation breaking table through three synchronous conveying belts and the air flotation system for breaking operations.

7.Automatic labeling:

Replace manual labeling. The printer automatically prints out a label recording the glass information, and the fingers of the labeling cylinder grab the label and stick it on the surface of the corresponding glass piece. The standard machine head for labeling has high labeling efficiency. (Customers are recommended to configure the labeling function )

Why Choose Us?

✔ Mature R&D Team – Continuous innovation for cutting-edge glass processing solutions.

✔ Original Factory Direct Supply – Competitive pricing without middlemen.

✔ 10+ Years Export Experience – Trusted by clients worldwide.

✔ OEM & Customization Support – Tailored solutions for your production needs.

✔ Fast Delivery & Reliable After-Sales – Minimize downtime with prompt service.

Features & Advantages

✅ Optimized Cutting Process – Three-table design (loading, cutting, breaking) ensures smooth workflow.

✅ Advanced Software – Optima optimization software maximizes material utilization.

✅ Flexible Configuration – 2+2 stations (adjustable) for high-volume production.

✅ High Load Capacity – Three grand arms per side for stable glass handling.

✅ Large Format Cutting – Supports max glass size: 3660×2800mm.

✅ Smart Factory Integration – Industry 4.0-ready with real-time monitoring.

Product Parameters:

| Feature | Specification |

|---|---|

| Cutting Precision | ±0.2 mm |

| Cutting Speed | Up to 200 m/min |

| Glass Thickness Range | 3 - 19 mm |

| Maximum Glass Size | 3660 x 2800 mm |

| Power Supply | 380V / 50Hz |

| Control System | PLC-controlled with touch screen |

| Installation | On-site support available |

Product Details:

The HSL-LSX3829 glass sheet cutting machine features a robust three-table design with dedicated loading, cutting and breaking stations. The advanced Optima software optimizes cutting patterns for maximum yield. With configurable above or underground rail systems and multiple loading arms, this assembly line offers exceptional flexibility for various glass processing needs.

Quality Control:

Our glass cutting assembly line undergo rigorous quality testing and inspections at every stage of production. We provide detailed mechanical test reports to verify performance and reliability.

Customization:

The HSL-CNC3829 glass sheet cutting machine can be customized to meet specific requirements. We offer options for rail configurations, station layouts, and even custom machine colors to match your facility.

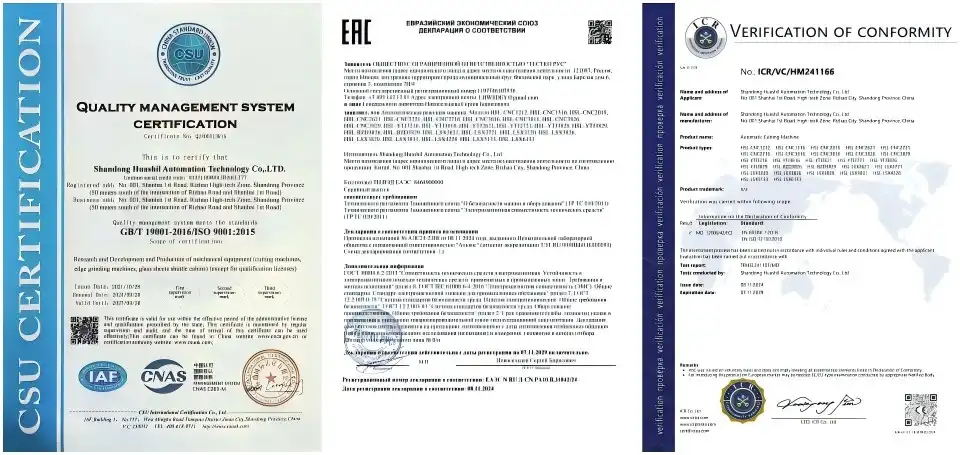

Certifications:

Huashil Machine holds all relevant industry certifications to ensure our products meet the highest quality and safety standards for global markets.

After-Sales Service:

We provide comprehensive after-sales support including installation guidance, operator training, maintenance services, and spare parts supply to keep your production running smoothly.

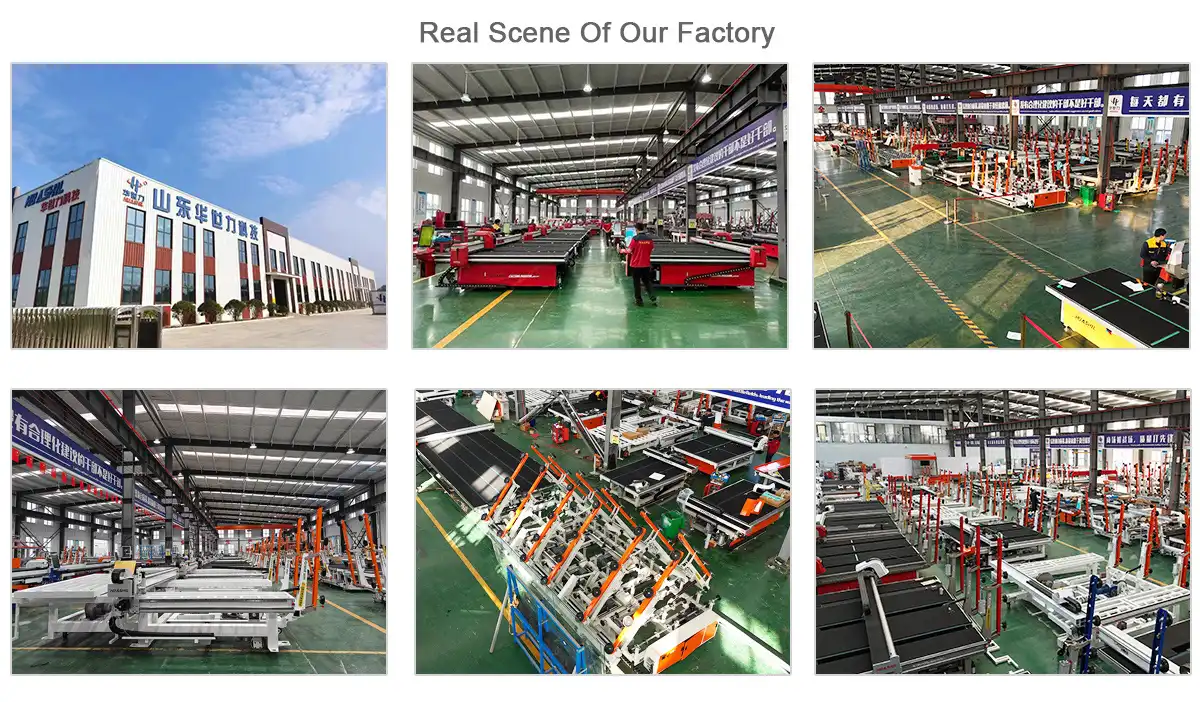

Company Introduction:

With over a decade of experience, Huashil Machine is a trusted name in glass processing equipment. Our commitment to innovation and quality has made us a preferred supplier for glass manufacturers worldwide.

FAQ:

Q: What types of glass can this assembly line process?

A: The HSL-LSX3829 can handle a wide range of glass types including architectural, automotive, furniture, and decorative glass.

Q: Is remote diagnostics support available?

A: Yes, we offer remote troubleshooting and diagnostics to minimize downtime.

Q: What is the warranty period?

A: We provide a standard 1-year warranty with options for extended coverage.

Q: Can the cutting speed be adjusted?

A: Yes, cutting speeds are fully adjustable to optimize for different glass types and thicknesses.

Q: Do you offer financing options?

A: We work with several financing partners to offer flexible payment terms for qualified buyers.

Contact Us:

For more information about our HSL-CNC3829 glass sheet cutting machine or other glass cutting assembly line solutions, please contact our sales team at salescathy@sdhuashil.com. Let Huashil Machine help optimize your glass processing operations with our advanced, reliable equipment.

YOU MAY LIKE