Glass cutting line

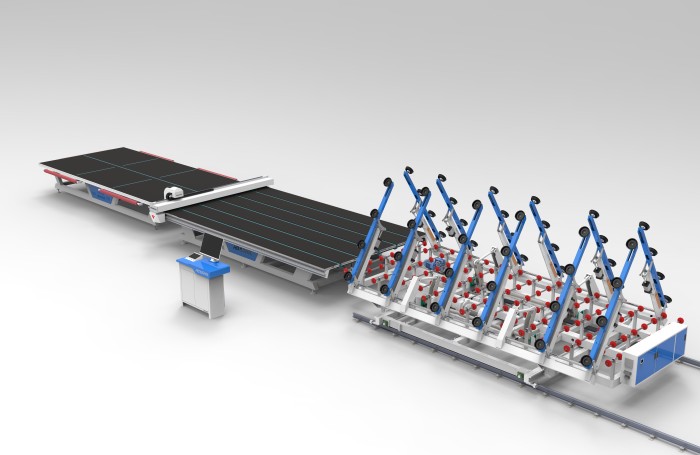

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has six grand arms

6. Max glass size:6100*3300mm

- Product Description

High-Precision Glass Cutting Lines for Seamless Glass Processing

Shandong Huashil Automation Technology Co., Ltd. specializes in high-precision glass cutting lines designed for architectural, automotive, and industrial glass processing. Our ISO-certified systems combine advanced automation with ±0.1mm accuracy, ensuring seamless production for projects demanding reliability. With over a decade of expertise, we deliver cost-effective solutions tailored to handle glass up to 6100x3300mm, optimized for energy efficiency and minimal downtime. Whether you’re fabricating tempered panels for skyscrapers or intricate automotive glass, our product technology adapts to your needs while meeting global certifications like CE and UL.

Why Our Glass Cutting Line Stands Out

- Fully Automated Operation: Reduce labor costs and human error.

- ±0.1mm Cutting Accuracy: Ideal for architectural and automotive precision.

- Energy-Efficient Design: Save 15–20% on power consumption.

- Customizable Configurations: Adapt to glass thicknesses from 3mm to 25mm.

- 10+ Years Durability: Built for 24/7 industrial use.

Certifications: ISO 9001, CE, UL, TÜV

Technical Specifications: HSL-LSX6133 Model

| Feature | Details | |

|---|---|---|

| Max Glass Size | 6100mm x 3300mm | |

| Tables | Loading, Cutting, Breaking | |

| Software | Optima® Optimization System | |

| Cutting Stations | 2+2 Configurable Stations | |

| Gripper Arms | 6 Arms per Side for Secure Handling |

Expandable Options: IoT integration, hybrid cutting modules, edge deletion units.

Applications Across Industries

Architectural Glass Processing

From skyscraper facades to laminated safety glass, our glass cutting line ensures flawless edges and minimal waste. The system handles jumbo panels (up to 6.1m) and curved shapes, streamlining projects for high-rise buildings and solar control glazing.

Automotive & Specialty Glass

Achieve micron-level precision for windshields, sunroofs, and smart mirrors. Our machines support tempered and coated glass, with AI-driven error detection to meet automotive OEM standards.

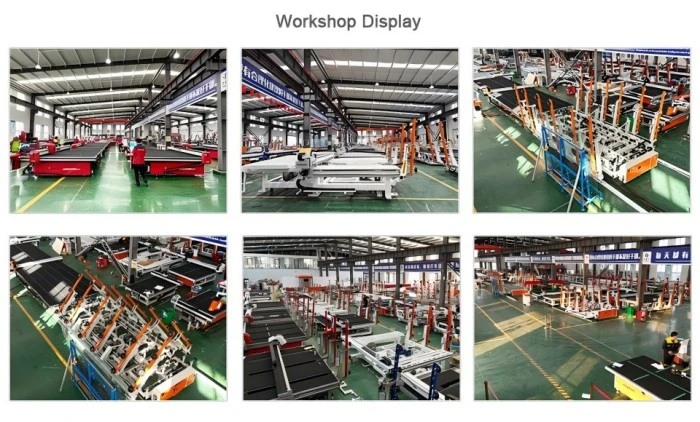

Why Partner with Shandong Huashil?

1. Vertical Integration: In-house R&D and manufacturing cut costs by 15–20% while ensuring traceable quality.

2. Agile Customization: Modify cutting speed, software, or loading systems in 4–6 weeks.

3. Global Support: 24/7 technical assistance and spare parts in 15+ countries.

4. ROI-Driven Design: Energy-saving components and <2% downtime guarantee faster returns.

After-Sales Support: Minimize Downtime, Maximize Output

- Remote Diagnostics: Instant troubleshooting via IoT-enabled systems.

- On-Site Training: Free operator and maintenance workshops.

- Lifetime Service Plans: Extended warranties and priority repairs.

Request a Custom Quote

Tell us your project needs:

- Glass type (tempered, laminated, coated).

- Annual production volume.

- Target automation level.

1,200+ lines installed globally | Response within 4 hours

FAQ: Your Questions Answered

1. Can your product handle irregular glass shapes?

Yes! Our Optima® software supports CAD file imports for bespoke designs.

2. What's the delivery time for urgent orders?

Standard lines ship in 60 days; expedited options available.

3. Are spare parts locally available?

We stock components in regional hubs for fast replacements.

4. Do you offer factory layout integration support?

Absolutely. Our engineers provide free layout optimization plans.

Contact Us

For more questions about glass cutting line, contact us today!

📧 Email: salescathy@sdhuashil.com

🌐 Global Offices: China, Germany, UAE, USA

Trusted by glass manufacturers since 2012.