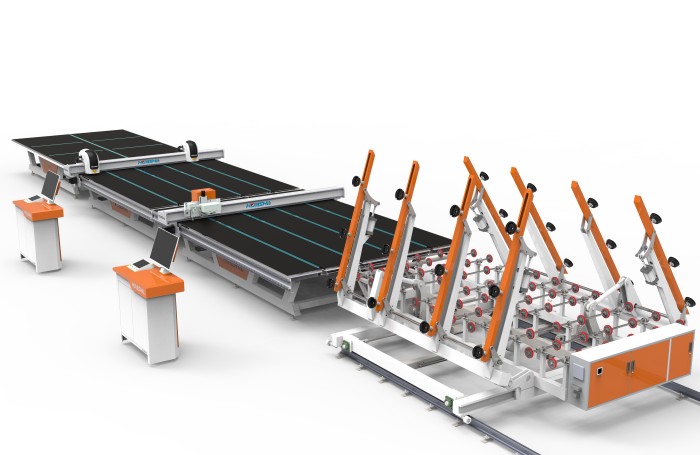

Glass transport table line

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has four grand arms

6. Max glass size:4200*2800mm

- Product Description

Precision Glass Transport Table Line for Seamless Production Workflows

Looking to upgrade your glass manufacturing efficiency? Our glass transport table line is engineered to streamline cutting, tempering, and coating processes with unmatched reliability. Designed for glass manufacturers and processors worldwide, this system combines precision engineering, modular flexibility, and robust durability to tackle your most pressing production challenges—from fragile glass handling to tight delivery timelines.

Why Choose Our Glass Transport Table Line?

- Precision Handling: Achieve ±0.5mm alignment accuracy with sensor-controlled arms, minimizing breakage.

- Corrosion-Resistant Build: Stainless steel components withstand harsh environments (e.g., coating zones).

- Modular Design: Easily integrate with existing OEM machinery or expand production lines.

- Energy Efficiency: Reduce power consumption by 20% with optimized motor systems.

- Safety First: Emergency stops, anti-collision sensors, and OSHA-compliant operation.

Technical Specifications & Customization

Model: HSL-LSX4228

Key Features:

- 3 Integrated Tables: Loading, cutting, and breaking stations.

- Optima Software: Real-time optimization for glass size and cutting patterns.

- Rail Options: Above/underground rails with 2+2 station configurations.

- Max Glass Size: 4200x2800mm (customizable for larger formats).

- Load Capacity: 500kg+/linear meter (upgradeable to 1000kg+).

Tailored Solutions:

- Adjustable widths/speeds for unique workflows.

- Material upgrades (e.g., ceramic rollers for high-temp zones).

- IoT-enabled predictive maintenance modules.

Built for Global Glass Manufacturers

Source Factory Advantage

As a direct manufacturer, we control costs and quality at every step, delivering glass transport table lines 30% faster than industry averages.

Expertise You Can Trust

- 10+ Years of Export Experience: Pre-certified designs (CE, UL, ISO 9001) for faster approvals.

- R&D Focus: 70% of our innovation targets glass-specific challenges like static control.

- Regional Warehouses: 15-day delivery from hubs in Germany, USA, and UAE.

End-to-End Support

- 24/7 Technical Assistance: On-call experts resolve issues within 4 hours.

- Lifecycle Analytics: IoT tools predict maintenance needs, reducing downtime by 30%.

Where Our Transport Solutions Excel

1. Automotive Glass Production: Handle oversized, curved sheets without slippage.

2. Architectural Glass Coating: Corrosion-resistant materials ensure longevity in humid zones.

3. High-Volume Tempering Lines: Rapid-cycle transport between heating and cooling stages.

4. SME Retrofits: Plug-and-play modules upgrade legacy systems affordably.

FAQ: Addressing Your Key Concerns

1. How do you ensure compatibility with our existing equipment?

We conduct a free layout audit and provide 3D simulations to verify fit.

2. What certifications do your systems hold?

All lines meet CE (EU), UL (North America), and ISO 9001 standards.

3. Can you handle urgent orders?

Yes! Our regional hubs ship ready-to-install units in 15 days.

4. What's included in after-sales support?

Warranty coverage, remote diagnostics, and optional on-site training.

For more details, email salescathy@sdHuashil.com.

Ready to Transform Your Production Line?

[Request a Custom Quote] • [Download Technical Specs] • [Schedule a Demo]

For more details, email salescathy@sdhuashil.com

Optimize your glass handling today with a glass transport table line built for precision, speed, and scalability.