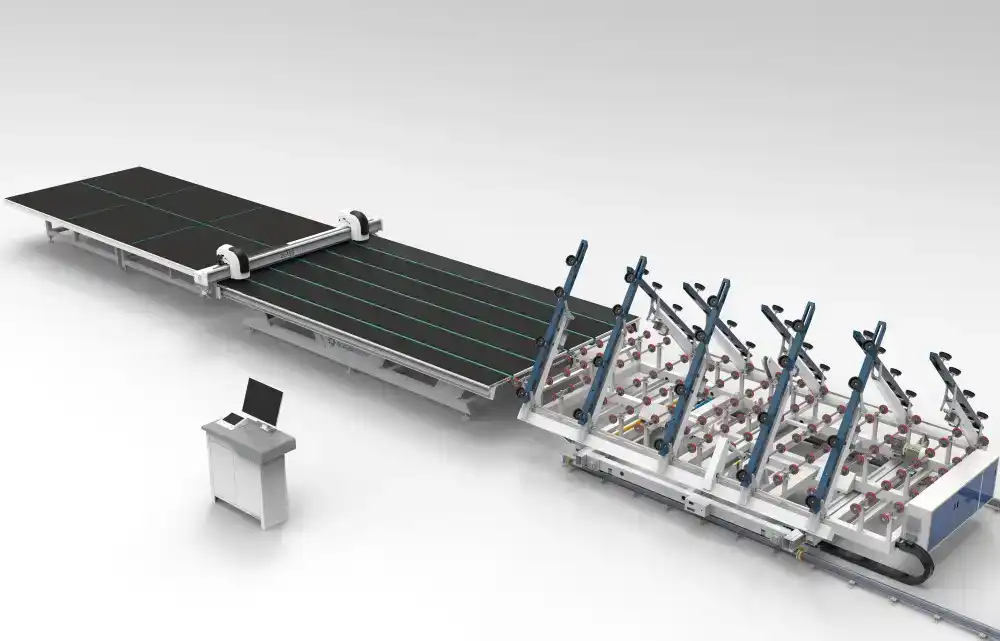

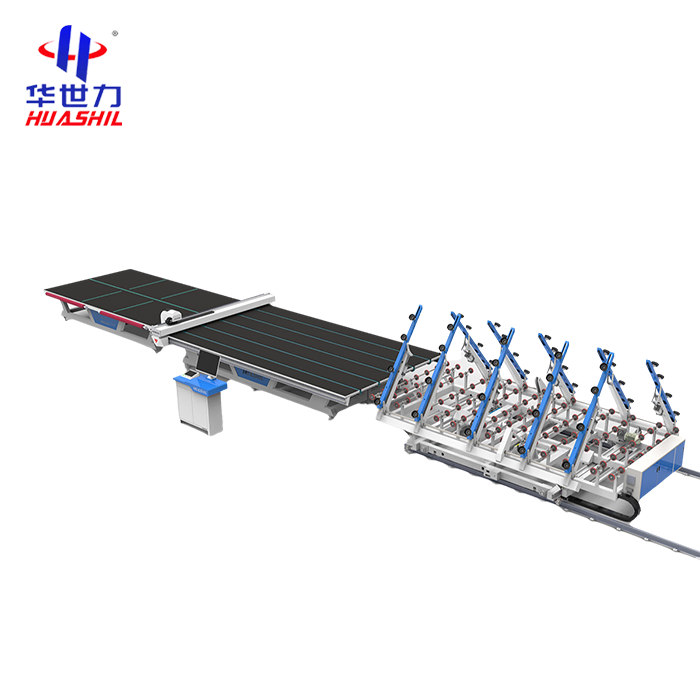

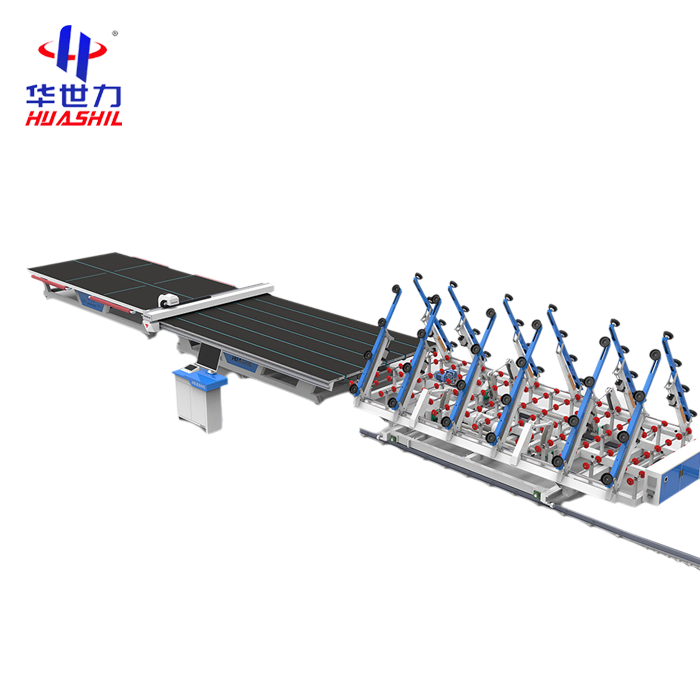

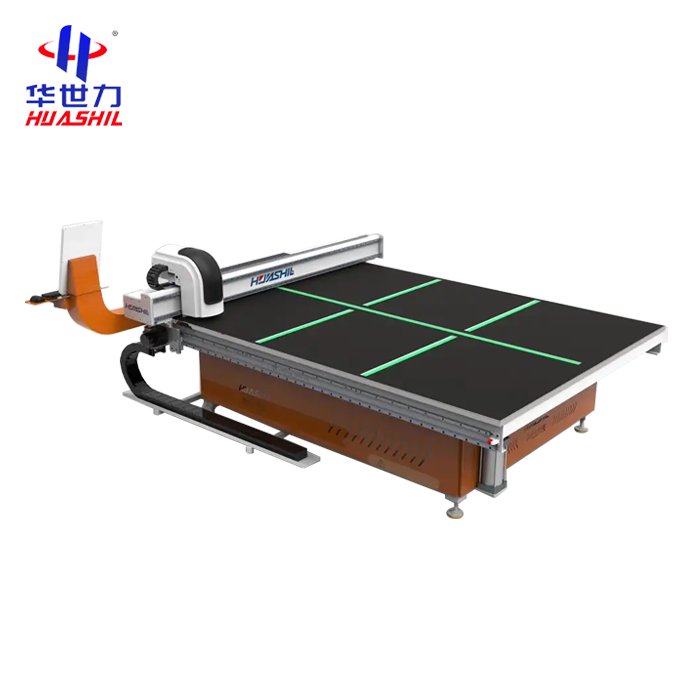

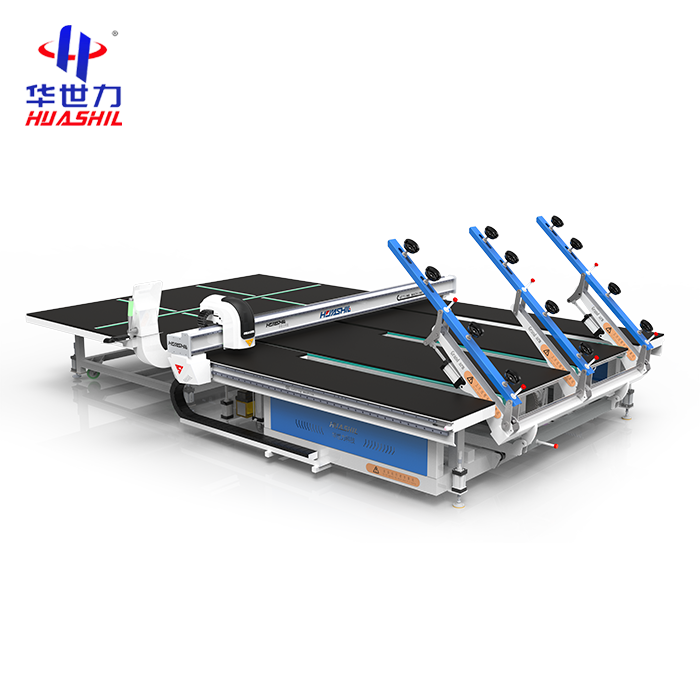

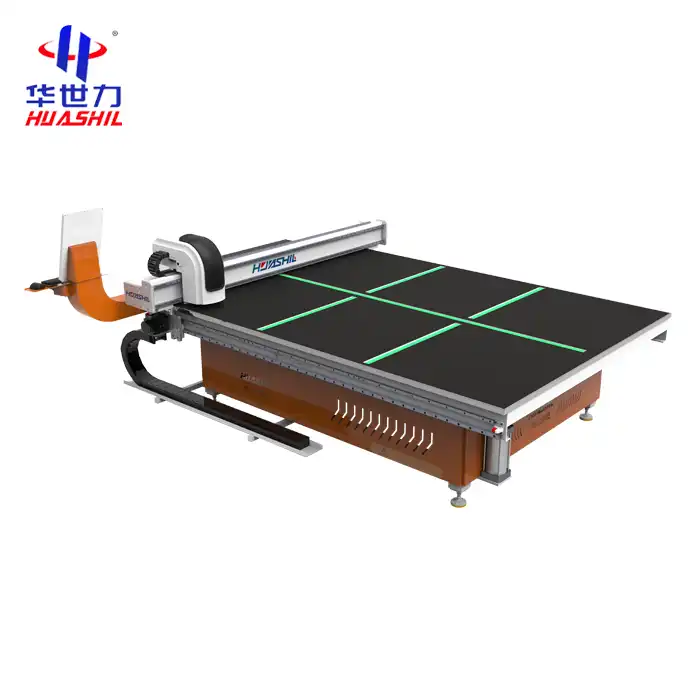

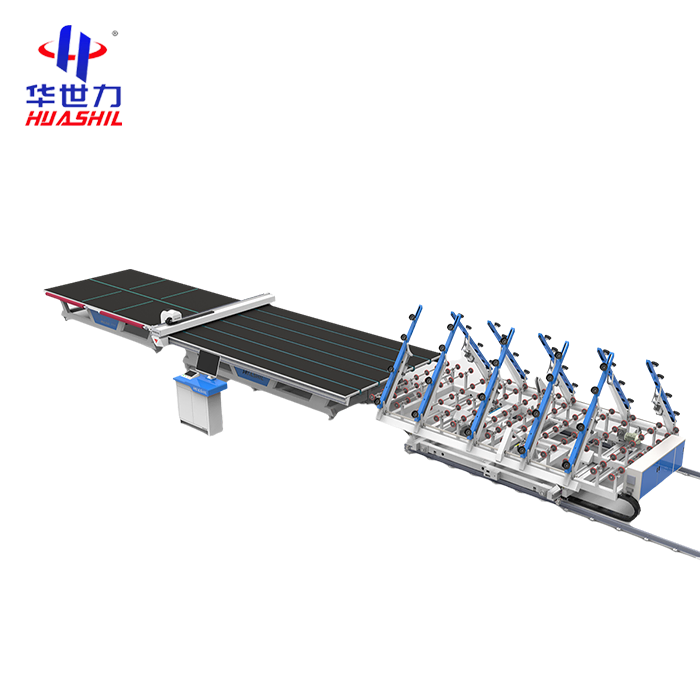

Double turn loading glass cutting line

2.Three tables:Loading table, cutting table, breaking table

3.Optimization software:Optima

4. Above(under) ground rail, 2+2 stations(can be set)

5.Each side has five grand arms

6. Max glass size:5100*3300mm

- Product Description

Double Turn Loading Glass Cutting Line - High-Efficiency Glass Processing Solution

Huashil Machine is a leading manufacturer and supplier of double turn loading glass cutting line. Our cutting-edge HSL-CNC3829 glass sheet cutting machine offers unparalleled precision and efficiency for glass manufacturers worldwide. With over a decade of export experience, Huashil Machine combines innovative technology with reliable after-sales support to meet the evolving needs of the global glass industry.

Why Choose Our Double Turn Loading Glass Cutting Line?

Industry 4.0 Ready: IoT-enabled for real-time monitoring and predictive maintenance.

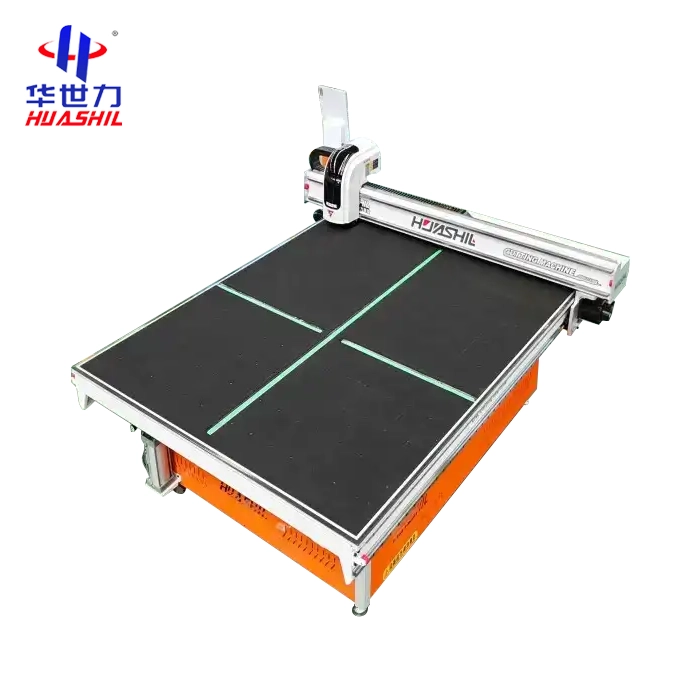

High Precision: ±0.1mm cutting accuracy for architectural, automotive, and solar glass.

Fast ROI: Automated loading/unloading reduces labor costs by 30%.

Global Support: 24/7 after-sales service with local technician networks.

Customizable: Adapts to glass thickness (3-25mm) and complex shapes.

Key Features & Advantages

✔ Dual-Turn Loading: Continuous operation minimizes downtime.

✔ Energy-Efficient: Cuts power consumption by 20% vs. conventional lines.

✔ Smart Diagnostics: Alerts for maintenance needs via mobile app.

✔ CE & ISO Certified: Complies with global safety standards.

✔ OEM Accepted: Tailored colors, logos, and configurations.

Product Parameters:

| Feature | Details |

|---|---|

| Maximum Glass Sheet Size | Up to 5100mm x 3300mm |

| Cutting Precision | ±0.2mm |

| Loading Method | Automatic Double Turn |

| Cutting Speed | 40-60 sheets per hour |

| Power Supply | 380V, 50Hz, 3 Phase |

| Control System | PLC + Touch Screen |

| Dimensions (L x W x H) | 20140mm x 3900mm x 1630mm |

Product Details:

The HSL-CNC3829 glass sheet cutting machine features a robust frame, precision linear guides, and advanced CNC control system. Its double turn loading glass cutting line mechanism ensures continuous operation, significantly reducing cycle times. The cutting bridge is equipped with high-speed servo motors for smooth, accurate movements.

Quality Control:

Our stringent quality control measures include:

- 100% component inspection

- Rigorous assembly process checks

- Comprehensive machine testing before shipment

- ISO 9001:2015 certified manufacturing processes

Customization Options:

- Cutting table size adjustments

- Integration with existing production lines

- Custom software interfaces

- Special glass handling adaptations

Certification:

- CE Certification

- ISO 9001:2015

- TÜV SÜD Safety Certification

After-Sales Service:

- 24/7 technical support

- On-site installation and training

- Regular maintenance programs

- Spare parts inventory management

Packaging:

- Seaworthy wooden crates

- Anti-shock foam protection

- Moisture-proof wrapping

- Secure anchoring for transportation

Company Introduction:

Huashil Machine, established in 2005, is a pioneer in glass processing equipment. We specialize in developing innovative solutions that drive efficiency and quality in glass manufacturing operations globally.

Our Factory:

Our state-of-the-art 50,000 m² facility houses advanced manufacturing equipment and a dedicated R&D center, ensuring we stay at the forefront of glass cutting technology.

Successful Cases:

-

Implemented HSL-CNC3829 for a leading automotive glass manufacturer, increasing output by 30%

- Customized solution for a solar panel producer, improving cutting precision and reducing waste by 15%

Exhibitions:

- Regular participant at Glasstec (Germany)

- Annual showcase at China Glass Exhibition

FAQ:

Q: What is the warranty period for the HSL-CNC3829?

A: We offer a standard 12-month warranty with options for extended coverage.

Q: Can the machine handle low-E glass cutting?

A: Yes, the HSL-CNC3829 is fully capable of processing low-E glass with high precision.

Q: How long does installation and training take?

A: Typically, installation and basic training can be completed within 5-7 working days.

Q: Is remote diagnostics available?

A: Yes, our machines are equipped with remote access capabilities for quick troubleshooting and support.

Q: Can the cutting patterns be customized?

A: Absolutely. Our software allows for full customization of cutting patterns to optimize material usage.

Contact Us:

For more information about our double turn loading glass cutting line or to discuss your specific requirements, please contact us at salescathy@sdhuashil.com. Experience the future of glass cutting with Huashil Machine's HSL-CNC3829 glass sheet cutting machine today!

YOU MAY LIKE

-

VIEW MORECNC glass cutting machine

VIEW MORECNC glass cutting machine -

VIEW MORECnc glass processing machine

VIEW MORECnc glass processing machine -

VIEW MOREDouble side glass cutting line

VIEW MOREDouble side glass cutting line -

VIEW MORESmall glass cutting machinery

VIEW MORESmall glass cutting machinery -

VIEW MOREGlass cnc cutting machine

VIEW MOREGlass cnc cutting machine -

VIEW MOREWindow cutting machine

VIEW MOREWindow cutting machine -

VIEW MORESmall cnc glass cutting machine

VIEW MORESmall cnc glass cutting machine -

VIEW MOREAuto glass cutting line

VIEW MOREAuto glass cutting line