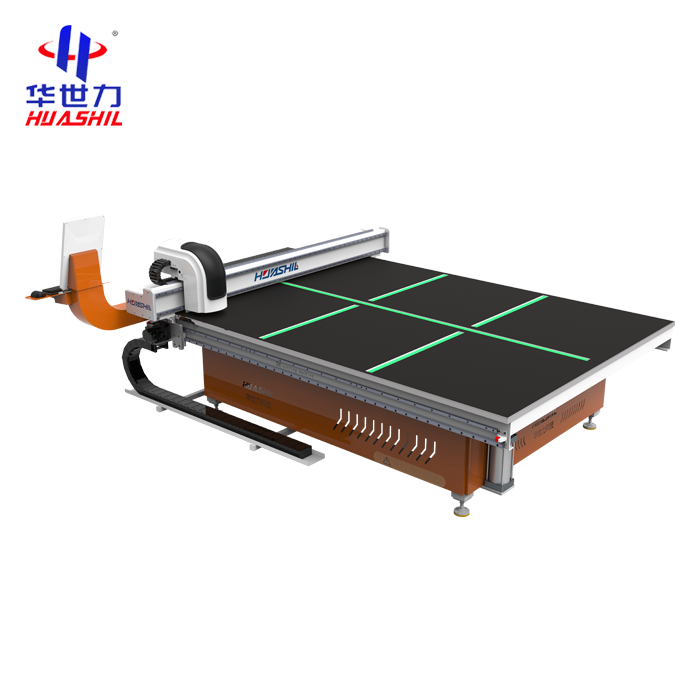

Furniture glass machine

2.Max glass size:3600*2800mm

3.Glass cutting thickness:2-19mm

4.Optimization software:Optima

5.Function: automatic pressure control,automatic edge finding,air flotation system, 360 degree remote control walking

6.Certificate:CE, ISO9001

- Product Description

Elevate Your Production with Precision Furniture Glass Machinery

Transform your glass processing workflow with Shandong Huashil's furniture glass machine—a game-changer for manufacturers seeking speed, accuracy, and OEM adaptability. Designed for luxury furniture brands and high-volume exporters, our HSL-CNC3829 model delivers ±0.1mm precision, automated workflows, and seamless integration into smart factories. With 10+ years of global expertise, we ensure ISO-certified quality and 30-day delivery to keep your production on track.

Why Choose Our Furniture Glass Machines?

🚀 High-Speed Automation

- Cut labor costs by 40% with CNC-controlled operations for glass cutting, edging, and drilling.

- Achieve 200 panels/hour throughput using advanced Optima optimization software.

🔧 Tailored for Your Needs

- Customize machine parameters for unique glass shapes, thicknesses (2-19mm), and finishes.

- Integrate IoT compatibility to sync with your existing production line controls.

🌍 Built for Global Demands

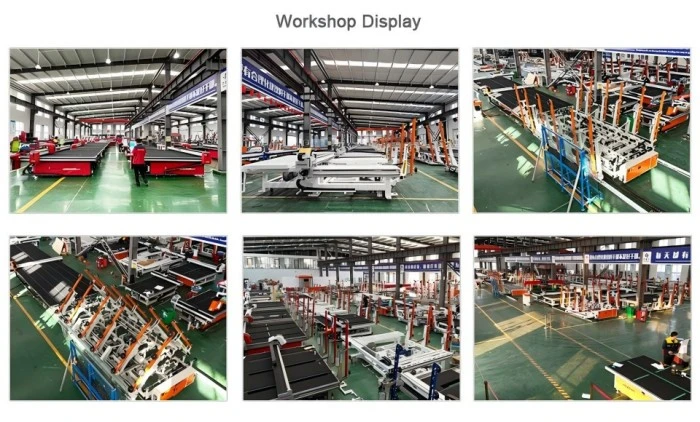

- CE and ISO9001-certified construction with corrosion-resistant materials for 24/7 durability.

- Pre-shipment testing and EXW/FOB support to guarantee on-time delivery worldwide.

Technical Specifications

| Model | HSL-CNC3829 | |

|---|---|---|

| Max Glass Size | 3600x2800mm | |

| Thickness Range | 2-19mm | |

| Software | Optima | |

| Key Features | Automatic edge finding, air flotation, remote control | |

| Certifications | CE, ISO9001 |

Where Our Machines Excel

1. Luxury Furniture Production

Craft intricate glass tabletops and cabinet panels with flawless edges that highlight precision craftsmanship and durability, ensuring every piece meets the highest standards required for high-end designs and modern luxury interiors.

2. Export-Oriented Manufacturing

Meet tight deadlines effortlessly with our advanced furniture glass machines, capable of processing sheets up to 3600mm in size for bulk orders, ensuring consistent precision, faster turnaround times, and reliable performance in demanding production environments.

3. Prototyping & Custom Projects

Adjust cutting paths and pressure settings in real-time for R&D experimentation, allowing engineers and designers to quickly test new concepts, refine prototypes, and optimize processes without disrupting ongoing production efficiency.

Global Support You Can Trust

✅ Pre-Sales Consultation

Get factory layout designs and technical reviews within 72 hours.

✅ 24/7 After-Sales

Remote diagnostics + multilingual support to resolve issues fast.

✅ Energy-Saving Tech

Servo motors reduce power consumption by 30% vs. conventional models.

Frequently Asked Questions

Q: Can your product handle curved glass for designer furniture?

A: Completely! Our R&D group programs custom cutting ways for any shape whereas keeping up ±0.1mm precision.

Q: How quickly can I get spare parts in Europe?

A: We stock components in regional hubs—most orders arrive within 3 business days.

Q: Is the product compatible with tempered glass?

A: Yes, it forms tempered, covered, and designed glass up to 19mm thickness.

Ready to Upgrade Your Production?

📩 Email Us Today

Get a personalized quote or technical brochure: salescathy@sdhuashil.com

💡 Why Wait?

Join 500+ producers around the world who believe our furniture glass machines for accuracy, unwavering quality, and unmatched OEM adaptability.

_1758246983094.jpg)