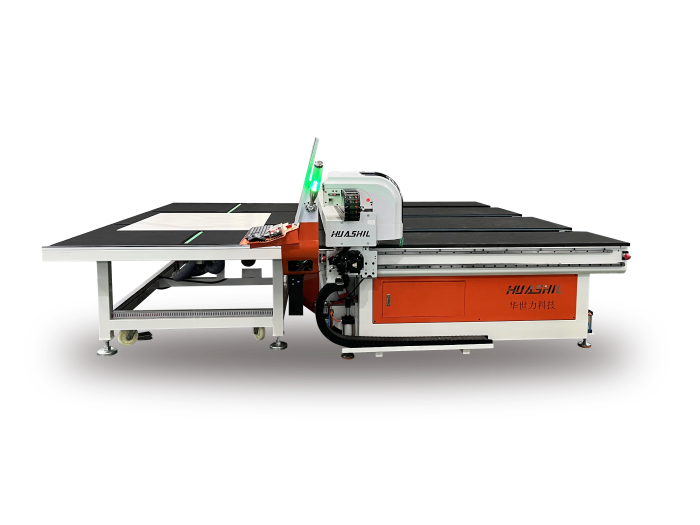

Special shape sintered stone cutting machines

2.Max glass size:3600*1600mm

3.Glass cutting thickness:3-12mm

4.Optimization software:Optima

5.Function: automatic pressure control,automatic edge finding,air flotation system, 360 degree remote control walking

6.Certificate:CE, ISO9001

- Product Description

Precision-Cut Special Shape Sintered Stone Cutting Machines – OEM-Ready Machines at Scale

If you’re searching for reliable special shape sintered stone cutting machines, you've found a partner with 15+ years of expertise. Our CNC-driven solutions handle curves, angles, and intricate designs with ±0.15mm precision, minimizing material waste and maximizing productivity. Whether you’re crafting bespoke countertops or large-scale architectural elements, our machines adapt to your toughest sintered stone projects.

Why Choose Our Sintered Stone Cutting Technology?

1. Multi-Axis CNC Precision

- Cut 3D profiles, bevels, and curves effortlessly with 5-axis control.

- AI-driven error detection reduces rework by 32%.

- Diamond-coated blades auto-adjust to stone density (Mohs 6–7).

2. Built for High-Volume Demands

- Operate 24/7 with ≤2% error rates.

- Process slabs up to 3300 x 1650mm and 50mm thick.

- Energy-efficient IE4 motors cut power costs by 18%.

3. Global Compliance & Safety

- Special shape sintered stone cutting machines come pre-certified with CE, ISO 9001, and UL standards.

- Dust-recycling systems meet OSHA/EU workplace regulations.

- 48-hour endurance testing before shipment.

Technical Specifications: Model HSL-CNC3616

| Feature | Specification | |

|---|---|---|

| Max Workpiece Size | 3600mm x 1600mm | |

| Cutting Thickness | 3–12mm (expandable to 50mm) | |

| Tolerance | ±0.15mm | |

| Software | Optima® Optimization Suite | |

| Voltage | 380V/220V (Configurable) |

OEM/ODM Flexibility for Your Brand

- Custom Branding: Machine casing, control panels, and software interfaces.

- Modular Upgrades: Add IoT connectivity or robotic arms later.

- Hybrid Systems: Combine waterjet and blade cutting in one unit.

Trusted by 500+ Global Partners

- Fast Logistics: 12 machines fit in a 40HQ container.

- Transparent Pricing: Save up to 30% on bulk orders (5+ units).

- 24/7 Support: Remote troubleshooting in <4 hours.

Frequently Asked Questions

1. How do your machines handle ultra-hard sintered stone?

Our diamond blades and hydraulic pressure control adapt to materials up to Mohs 7 hardness, ensuring clean cuts without chipping.

2. Can I integrate your product with my existing production line?

Yes! We provide API-ready software and modular designs for seamless integration.

3. What certifications do your machines hold?

All units comply with CE, ISO 9001, and region-specific standards (UL, EAC, GB).

4. How quickly can I get spare parts?

We dispatch components within 48 hours via DHL/FedEx, with pre-negotiated rates.

5. Do you offer consignment stock for distributors?

Yes – contact us to discuss tailored inventory agreements.

Ready to Upgrade Your Cutting Capacity?

📩 Request a Custom Quote: Email Huashil.com">salescathy@sdhuashil.com for OEM pricing.

🎥 See It Live: Book a live machine demo via Zoom or onsite visit.

📦 Fast-Track Delivery: Get standard units shipped in 5–7 weeks.

Trusted by fabricators in 27 countries, our special shape sintered stone cutting machines deliver the precision your high-value projects demand. Let's shape your success together!