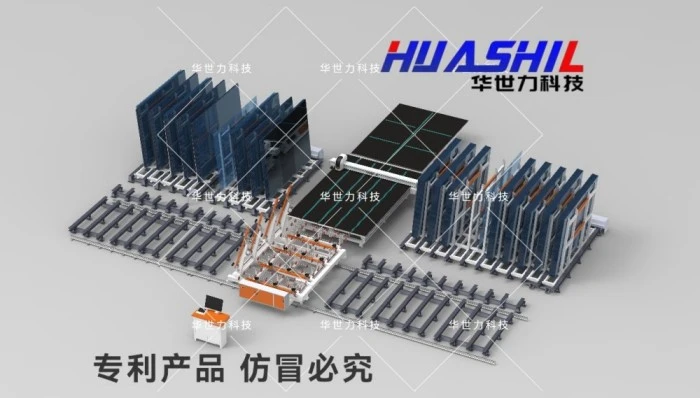

Furniture cutting equipment

2.Max glass size:3660*2800*mm

3.Glass cutting thickness:2-19mm

4.Optimization software:Optima

5.Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system, with breaking table,360 degree remote control walking

6.Certificate:CE, ISO9001 7.Glass conveying by synchronous belts

- Product Description

Industrial-Grade Furniture Cutting Equipment: Precision Meets Productivity

Transform your furniture manufacturing with furniture cutting equipment engineered for speed, accuracy, and versatility, designed to help producers meet the growing demands of modern markets. Our HSL-YTJ3829 model delivers ±0.1mm cutting precision across wood, laminates, and composites up to 19mm thick—making it ideal for high-volume cabinet panels, durable upholstery frames, and intricate custom curved components. Backed by over 15 years of CE/ISO-certified manufacturing expertise, we combine proven reliability with advanced automation at factory-direct prices, reducing material waste by 22% while maximizing overall production efficiency and long-term value.

Why Our Cutting Solutions Stand Out

Unmatched Technical Excellence

- Laser-guided accuracy: Achieve ±0.005" tolerances consistently

- Multi-layer cutting: Process 2-19mm materials without recalibration

- AI defect detection: Minimize rework with real-time quality control

- Energy-efficient operation: 30% lower power consumption vs. industry averages

Built for Global Furniture Makers

Whether you're crafting bespoke designer pieces with intricate detailing, working on customized interior solutions, or mass-producing flat-pack systems for large-scale distribution, our furniture cutting equipment adapts to your needs:

| Application | Key Benefit | |

|---|---|---|

| Cabinet Panel Cutting | 3660x2800mm max size capacity | |

| Curved Component Work | 360° remote-control positioning | |

| Batch Production | Optima software optimization |

Precision Engineered for Your Success

Core Specifications (HSL-YTJ3829)

- Max Glass Size: 3660x2800mm

- Cutting Thickness: 2-19mm

- Automation Features:

- Automatic loading/unloading

- Air flotation workpiece handling

- IoT-enabled performance tracking

Global Compliance & Reliability

- Certifications: CE, ISO9001

- Durability: 50,000+ hour MTBF

- Regional Adaptations:

- 220V/380V voltage compatibility

- REACH-compliant components for EU

- OSHA-aligned safety protocols for NA

FAQ: Furniture Cutting Equipment

1. How does your equipment reduce downtime in 24/7 factories?

Our predictive maintenance alerts and 48-hour spare parts delivery from regional hubs keep your product operational 98% of the time, minimizing unplanned stoppages and ensuring continuous productivity in demanding around-the-clock manufacturing environments.

2. Can I upgrade older models with new automation features?

Yes! Our modular design allows retrofitting AI calibration or IoT tracking to existing machines, making it easy to enhance performance, extend equipment lifespan, and stay competitive with the latest smart manufacturing technologies.

3. What customization options do you offer?

Choose from 12 blade configurations, custom software interfaces, or bespoke conveyor widths, giving you the flexibility to adapt the system precisely to your production requirements and achieve maximum efficiency without compromising quality.

4. How do you ensure cutting consistency with mixed materials?

Patented pressure control systems automatically adjust force between wood (18kN) and acrylic (5kN).

Experience the Huashil Difference

Free Cutting Test Program, See our furniture cutting equipment in action with a no-obligation material sample processing.

Need Immediate Assistance?

Email our engineering team: Huashil.com">salescathy@sdhuashil.com

Custom quotes prepared within 4 working hours

_1758243230804.jpg)