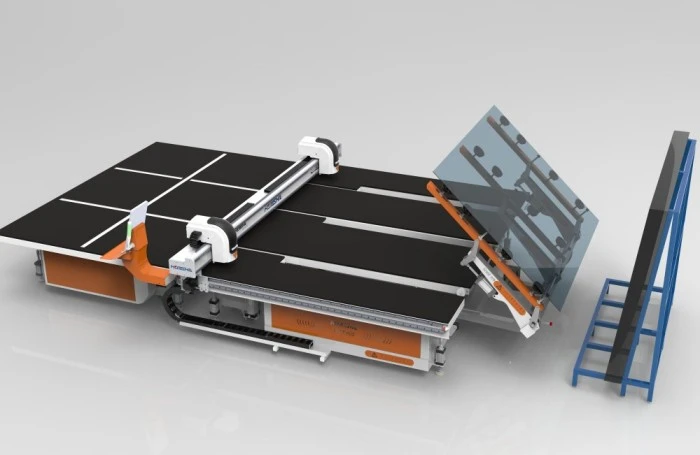

Gtm glass loading machine

2.Max glass size:3660*2800*mm

3.Glass cutting thickness:2-19mm

4.Optimization software:Optima

5.Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system, with breaking table,360 degree remote control walking

6.Certificate:CE, ISO9001 7.Glass conveying by synchronous belts

- Product Description

GTM Glass Loading Machine: Precision Automation for Modern Glass Factories

In high-volume glass manufacturing, every millimeter and minute counts. The GTM glass loading machine redefines efficiency with ISO-certified automation, cutting-edge precision, and global compliance. Designed for float, tempered, and laminated glass producers, this system eliminates manual handling errors while boosting output by up to 150 panels/hour. Keep reading to discover how our vertical manufacturing expertise delivers 35% faster ROI than traditional loading systems.

Why Smart Factories Choose GTM Automation

1. Unmatched Precision, Near-Zero Breakage

Our dual-arm robotic system handles sheets from 3mm to 19mm thickness with ±0.5mm accuracy, reducing breakage rates to 0.15%—well below the industry 1% average. Proprietary air flotation and edge-finding tech ensure scratch-free transfers, even for oversized panels up to 3660x2800mm.

2. Plug-and-Play Customization

- Size Flexibility: Adapts to production lines from 2.2m to 6.5m lengths

- Smart Integration: Pre-configured PLC interfaces with Siemens/Yaskawa drives

- Climate Ready: Operates reliably in -10°C to 50°C environments

3. Source Factory Advantages

As a vertically integrated manufacturer, we control every component—from CNC-machined frames to Optima optimization software. This eliminates third-party markups, offering 25% cost savings versus competitors.

Technical Specifications at a Glance

| Feature | Specification | |

|---|---|---|

| Max Load Capacity | 3,200kg | |

| Energy Consumption | ≤18.5kW (35% less than standard models) | |

| Certifications | CE, ISO 9001, ISO 13849 | |

| Remote Capabilities | 360° control, IoT diagnostics |

5 Reasons Global Brands Trust Us

1. Faster Deployment

Regional adaptation kits pre-install voltage (220V/415V) and language settings—your factory runs in 15 days, not months.

2. Transparent Cost Structure

All-inclusive FOB/CIF quotes with duty calculators eliminate hidden fees.

3. Lifecycle Support

Blockchain-powered digital twins predict maintenance needs before failures occur.

4. ESG Alignment

Energy recovery systems meet EU Green Deal standards, cutting CO₂ by 18 tons/year per gtm glass loading machine.

5. Risk-Free Trial

Free 3D line simulation verifies compatibility with your existing setup.

Frequently Asked Questions

Q: Can the product handle mixed production (e.g., solar + architectural glass)?

A: Yes! Our modular design allows quick tooling changes between glass types. Specify your requirements during the free line audit.

Q: What if we need urgent technical support?

A: Our Mexico/Germany/India service centers provide <72hr onsite response. Multilingual engineers are available 24/7 via WhatsApp or email.

Q: How does your pricing compare to European brands?

A: Vertical integration lets us offer Siemens-grade quality at 30% lower costs. Request a TCO comparison sheet to see 5-year savings.

Q: Can we upgrade an older GTM model instead of buying new?

A: Absolutely! Our scalable architecture allows capacity boosts via modular add-ons. Send your machine ID for a retrofit quote.

Ready to Transform Your Glass Handling?

📞 Email Huashil.com">salescathy@sdhuashil.com for:

- Instant access to our 850+ client success portfolio

- Customized ROI calculation based on your production volume

- Live gtm glass loading machine factory tour scheduling (Shandong or virtual)

Serving Fortune 500 glass producers across 27 countries since 2013.

_1758245295232.jpg)