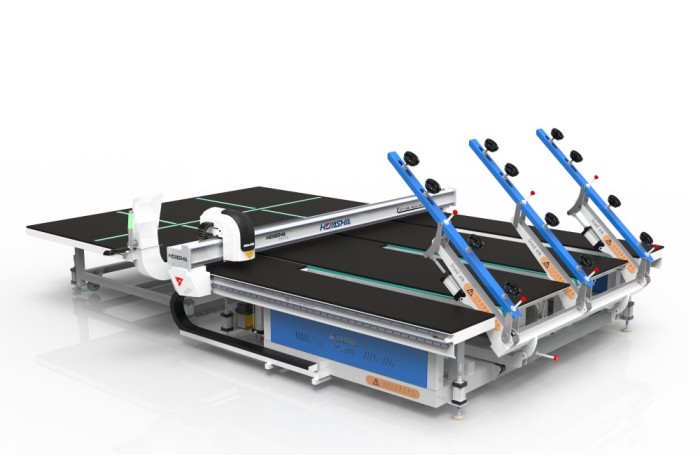

High-performance glass processing equipment

2.Max glass size:3660*2800*mm

3.Glass cutting thickness:2-19mm

4.Optimization software:Optima

5.Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system, with breaking table,360 degree remote control walking

6.Certificate:CE, ISO9001 7.Glass conveying by synchronous belts

- Product Description

High-Performance Glass Processing Equipment for Precision Manufacturing

In industries where precision and speed define profitability, high-performance glass processing equipment isn't just a tool—it's the backbone of your production line. At Shandong Huashil Automation Technology, we engineer machinery that delivers 30% faster cycle times, ±0.1mm cutting accuracy, and 20% lower energy costs compared to conventional systems. Whether you’re shaping automotive windshields, smartphone screens, or architectural glass panels, our solutions are built to maximize your ROI while minimizing downtime.

Why Our Glass Processing Systems Stand Out

- Factory-Direct Pricing: Full in-house manufacturing control ensures ISO 9001-certified quality without middleman markups.

- Smart Automation: AI-driven calibration adapts to glass thickness (0.5-25mm) and reduces material waste by 18%.

- Multi-Process Integration: Cut, grind, polish, and temper glass in one machine for seamless workflows.

- Proven Durability: IP65-rated components withstand abrasive dust and 24/7 operation with <2% defect rates.

Technical Specifications: HSL-YTJ3829 Model

| Parameter | Specification | |

|---|---|---|

| Max Glass Size | 3660x2800mm | |

| Cutting Thickness | 2-19mm (expandable to 0.5-25mm via OEM) | |

| Optimization Software | Optima® AI Suite | |

| Key Functions | Automatic loading, edge finding, air flotation, 360° remote control | |

| Certifications | CE, ISO 9001, IATF 16949 |

Custom-Built for Your Industry

Automotive & Electronics

- Achieve ≤0.01mm tolerance on curved or ultra-thin glass (e.g., Gorilla Glass).

- AI vision systems detect micro-cracks during polishing.

Construction & Solar

- Process laminated or tempered panels up to 3660mm long.

- Modular tool heads swap in <15 minutes for mixed-batch orders.

OEM/ODM Solutions

- Redesign software interfaces, conveyor layouts, or pressure settings in <4 weeks.

- 3D configurator lets you preview customizations in real time.

5 Reasons Global Leaders Choose Us

1. 12 Years of Innovation: 500+ systems operational across 30 countries.

2. 15-Day Fast-Track Production: Our high-performance glass processing equipment features standard models that ship in half the time of the industry average.

3. 72-Hour Support Guarantee: Multilingual technicians resolve 90% of issues remotely.

4. Transparent Compliance: CE, RoHS, and ANSI/IGMA certifications included.

5. Lifetime ROI: Energy-efficient motors and standardized spare parts cut TCO by 35%.

FAQ: What Buyers Like You Ask

1. Can your equipment handle irregular glass shapes for custom automotive sunroofs?

Yes! Our OEM-ready platforms adjust tool paths for arcs, angles, or cutouts via CAD file uploads.

2. How do you ensure precision in high-volume runs?

Patented air flotation tables reduce friction, while real-time sensors auto-correct cutting depth every 0.5 seconds.

3. What's included in your after-sales support?

Free AR-guided maintenance tutorials, 24/7 parts dispatch, and annual efficiency audits.

4. Do you provide ESG compliance reports?

Yes—request our carbon footprint analysis and recycling guides for EU/NA compliance.

5. What's the lead time for the Middle East?

GCC orders ship in 18-25 days with localized voltage/pressure presets.

Ready to Upgrade Your Production Line?

📞 Get a Free high-performance glass processing equipment Process Optimization Analysis

Our engineers will review your workflow and recommend upgrades to boost output by 20-50%.

📥 Download the Technical Dossier: [Link], Explore full specs, compliance details, and case studies.

🌍 Global Offices: Fast local support in your time zone.

📧 contact us Today: salescathy@sdhuashil.com