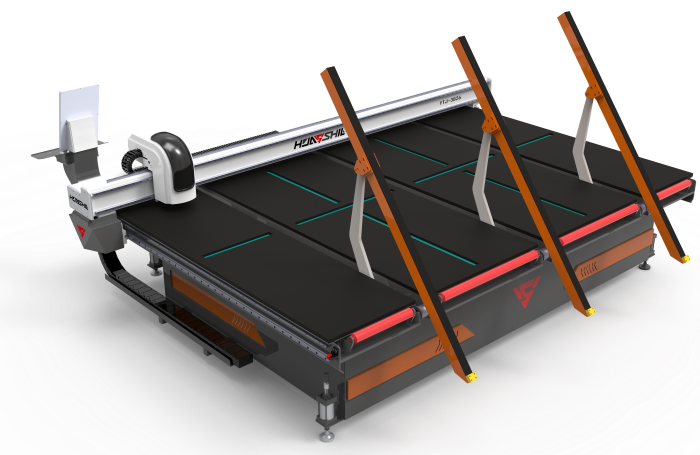

Industrial glass cutting table

2.Max glass size:3660*2800*mm

3.Glass cutting thickness:2-19mm

4.Optimization software:Optima

5.Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system, with breaking table,360 degree remote control walking

6.Certificate:CE, ISO9001 7.Glass conveying by synchronous belts

- Product Description

Precision Industrial Glass Cutting Tables for Bulk Manufacturing

When your production line demands flawless accuracy in glass processing, our industrial glass cutting table solutions deliver unmatched precision and reliability. Designed for manufacturers requiring ±0.1mm tolerance in automotive, architectural, and specialty glass applications, these systems combine cutting-edge automation with decades of engineering expertise.

Why Choose Our Glass Cutting Systems?

- ±0.1mm Cutting Precision

Achieve automotive-grade accuracy across 2-19mm glass thicknesses with proprietary motion control.

- Seamless Automation

Integrated loading/unloading, air flotation transport, and remote-controlled operation minimize manual handling.

- Energy-Saving Design

Servo motors reduce power consumption by 20% compared to conventional models.

- Global Compliance Ready

Pre-certified for CE, UL, and regional standards to accelerate cross-border deployment.

Core Advantages for Your Production Needs

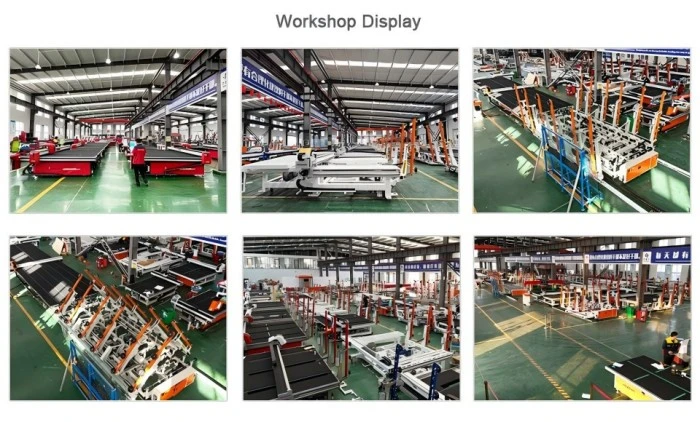

🔧 Source Factory Quality Control

Every industrial glass cutting table is manufactured in-house using Siemens PLCs and Bosch drive systems, with full ISO 9001 traceability from raw materials to final testing.

📊 Proven Durability

Over 100 systems annually exported since 2015 demonstrate our commitment to 80,000+ hour operational lifespans in 24/7 glass factories.

🛠️ Custom Engineering Expertise

Adapt our HSL-YTJ3829 base model to your exact requirements:

- Glass sizes up to 3660x2800mm (expandable)

- Hybrid configurations for mixed soda-lime/tempered glass

- Industry 4.0 integration via OPC UA/MQTT protocols

⚡ Rapid Global Support

Our 24/7 technical team guarantees:

- Multilingual troubleshooting within 2 hours

- Critical spare parts shipped worldwide in <72 hours

- Onsite commissioning available in 35+ countries

Technical Specifications

| Parameter | Specification | |

|---|---|---|

| Max Glass Size | 3660x2800mm (customizable) | |

| Thickness Range | 2-19mm (expandable to 25mm) | |

| Cutting Accuracy | ±0.1mm | |

| Optimization Software | Optima® with AutoCAD/SolidWorks plugins | |

| Certifications | CE, ISO 9001, RoHS |

Customization Workflow

1. Share Requirements

Provide glass dimensions, daily output goals, and automation level.

2. Co-Design Solution

Our engineers prototype your optimized configuration in 15 days.

3. Test & Deploy

Validate performance with onsite trials before bulk production.

ROI-Driven Performance

- 40% Faster Setup

Pre-calibrated modules reduce installation time vs. traditional systems.

- Predictive Maintenance

IoT sensors cut unplanned downtime by 30% through wear monitoring.

- Lifetime Cost Control

5-year warranty + energy-efficient design delivers 18% lower TCO over decade.

Global Compliance & Logistics

Certified Worldwide Deployment

- CE (Europe)

- UL 508A (North America)

- CCC (China)

- EAC (Eurasia)

Flexible Shipping

- Standard lead time: 50 days

- Full-custom orders: 65 days

- Incoterms: FOB Qingdao, CIF options

Take the Next Step

✅ Free Efficiency Audit

Our engineers will analyze your current glass cutting costs and propose optimizations.

✅ Instant Tech Dossier

Download full specifications, compliance details, and case studies.

✅ Live Demo Booking

See our product in action – virtually or onsite.

Contact Our Engineers Now

FAQ

1. How do you maintain ±0.1mm accuracy in high-volume production?

Our linear motion systems undergo laser calibration every 500 operating hours, with automatic compensation for thermal expansion.

2. Can the system handle laminated glass for automotive windshields?

Yes – specify your layer configuration during customization for optimized pressure control.

3. What's included in the 5-year warranty?

All mechanical components excluding consumables (cutting wheels, belts), with priority support access.

4. How quickly can you modify cutting patterns?

Optima® software updates tool paths in <3 minutes via drag-and-drop interface.

5. Do you provide operator training?

Yes – comprehensive training packages available onsite or through live VR simulations.

Contact Us

For more questions about industrial glass cutting table, optimize Your Glass Cutting Workflow Today

Email: Huashil.com">salescathy@sdhuashil.com