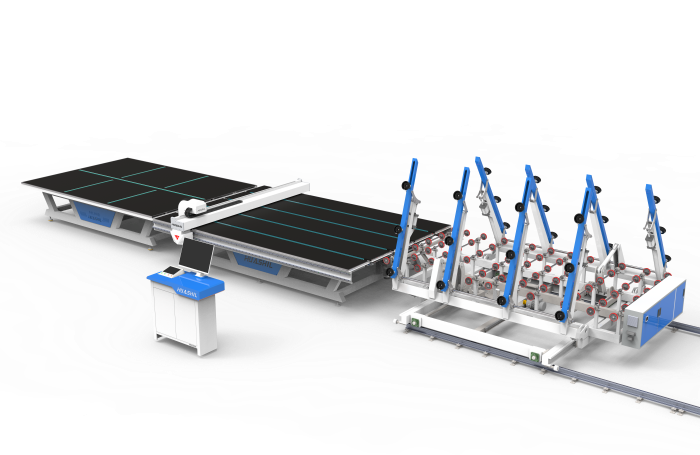

Industrial glass cutting and laminating systems

2、Cutting the maximum length:3800mm

3、Cutting the minimum length:300mm

4、Glass thickness :3+3 ~ 8+8mm

5、The film thickness of laminated glass0.38mm—1.52mm

6、Cutting speed:100m/min

7、Glass positioning: Photoelectric positioning

8、Work table height :820±50mm

- Product Description

High-Precision Industrial Glass Cutting And Laminating Systems for Global Manufacturers

For industrial glass manufacturers seeking unmatched precision and efficiency, our industrial glass cutting and laminating systems redefine production standards. Designed for architectural, automotive, and specialty glass applications, these systems combine AI-driven automation with ±0.1mm cutting accuracy to minimize waste and maximize output. With 500+ installations worldwide, we deliver tailored solutions that adapt to your unique workflows while ensuring compliance with CE, ISO, and regional certifications.

Core Benefits of Our Glass Processing Solutions

- 30% Faster Production: Reduce cycle times with AI-optimized batch processing.

- Zero Material Waste: Advanced nesting algorithms ensure ≤5% scrap rates.

- 24/7 Support: Remote diagnostics resolve 85% of issues within 2 hours.

- Future-Ready Design: Integrate with IoT platforms for predictive maintenance.

Key Features Driving Industry Leadership

Multi-Axis CNC Cutting Technology

- Cut complex shapes (curved, angled, or tempered glass) with laser-guided precision.

- Handle thicknesses from 0.5mm ultra-thin glass to 25mm bulletproof laminates.

High-Speed Vacuum Laminating Lines

- Bond layers at 120 panels/hour using uniform pressure control (0.8–1.2 MPa).

- Compatible with PVB, EVA, and SGP interlayers (0.38–1.52mm).

Smart Factory Integration

- Real-time dashboards monitor energy use, output quality, and OEE.

- Siemens PLCs enable seamless integration into existing production lines.

Technical Specifications

| Parameter | Specification | |

|---|---|---|

| Max Cutting Length | 3800mm | |

| Laminating Speed | Up to 120 panels/hour | |

| Positioning Accuracy | ≤±0.1mm (photoelectric calibration) | |

| Power Compatibility | 110V–480V, 50/60Hz |

Applications Across Industries

1. Architectural Glass

- Insulated units, curved facades, and acoustic laminates.

2. Automotive Glass

- Windshields, sunroofs, and HUD-compatible heads-up displays.

3. Specialty Glass

- Solar panel laminates, bulletproof glass, and smart mirrors.

Why Partner With Us?

Source Factory Advantage

- Direct pricing using Siemens/ABB components, cutting middlemen costs by 15–20%.

Quality Built to Last

- 3-stage inspections (pre-production, in-process, final) ensure 99.98% defect-free delivery.

Global Compliance Made Simple

- Industrial glass cutting and laminating systems, pre-certified to meet CE, EAC, and GCC standards, enable faster market entry.

Customization Without Compromise

- Modify machine dimensions, software interfaces, or material handling in 15–30 days.

Frequently Asked Questions

Q: Can your systems handle irregularly shaped automotive glass?

A: Yes! Our multi-axis CNC cutters process curves and angles with ±0.1mm repeatability.

Q: Do you offer energy-efficient models for EU factories?

A: Absolutely. Our EcoDrive mode reduces power consumption by 22% during idle periods.

Q: How quickly can you deliver OEM projects?

A: Prototypes in 15 days, full production in 30 days – with strict IP protection.

Q: What if we encounter technical issues post-installation?

A: Our 30+ global service hubs provide on-site support within 72 hours.

Ready to Transform Your Glass Production?

Request a Free Efficiency Audit

Submit your glass dimensions and annual output → Receive a tailored industrial glass cutting and laminating systems proposal in 8 hours.

📧 contact us Today: Huashil.com">salescathy@sdhuashil.com

[Download Brochure] | [Schedule Live Demo]