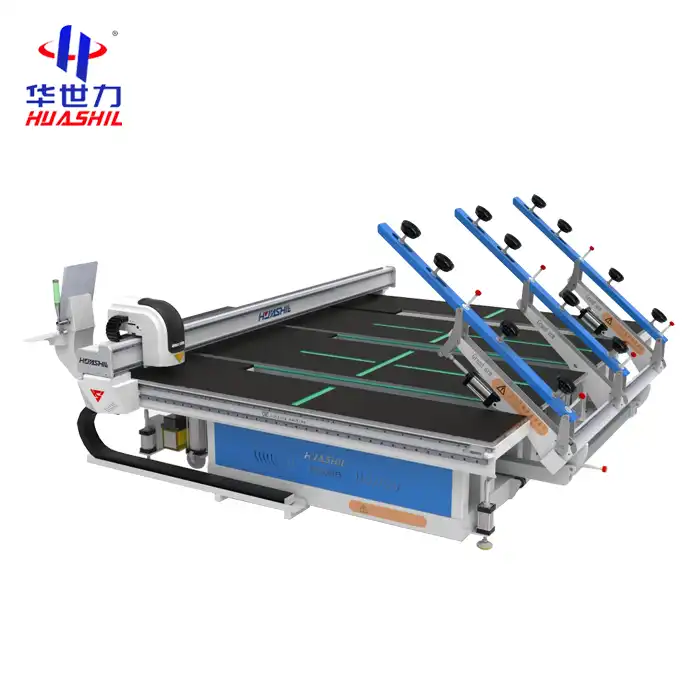

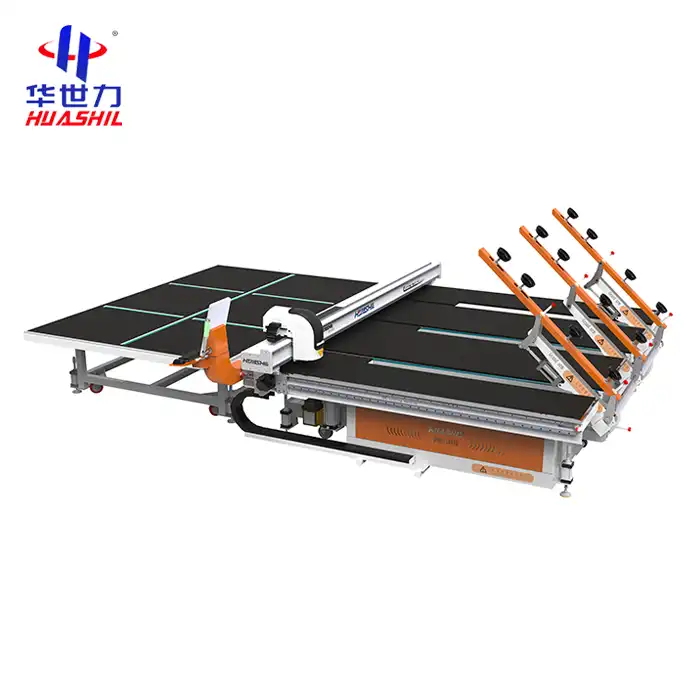

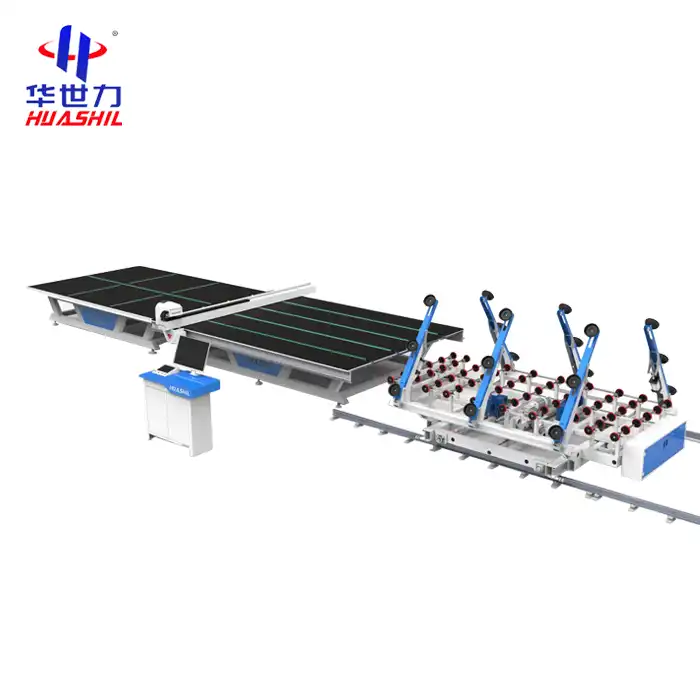

Furniture cabinet glass cutting machine

Max glass size:3660*2800*mm

Glass cutting thickness:2-19mm

Dimension:4925*3750mm

Optimization software:Optima

Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system,ejector rod on the cutting table,360 degree remote control walking

Certificate:CE, ISO9001

- Product Description

Huashil Machine: Your Trusted Partner for Furniture Cabinet Glass Cutting Machines

Huashil Machine is a leading manufacturer and supplier of high-quality furniture cabinet glass cutting machine. Our HSL-CNC3829 glass sheet cutting machine offers unparalleled precision, efficiency, and versatility for furniture manufacturers. With over a decade of export experience, we provide innovative solutions to streamline your glass cutting processes.

|

Frame |

Made of national standard 80*80*3, 100*50*2.5 and 50*50*2.5 square tubes welded together |

|

Countertop |

High-density waterproof board with anti-static industrial felt on the surface to ensure stable use in humid environments. |

|

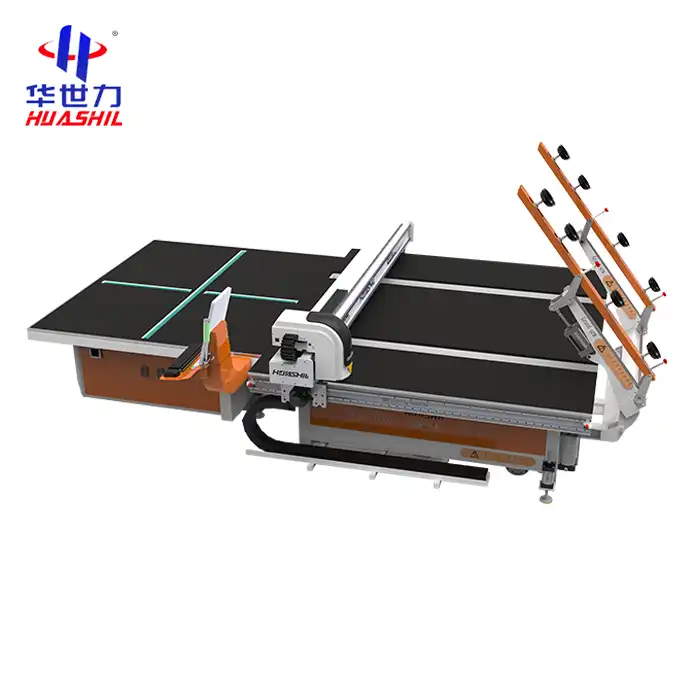

Ejector rod |

It is equipped with 1 horizontal and 2 vertical ejector rods; the ejector rods adopt a connecting rod linkage mechanism and are driven by a cylinder to ensure synchronous lifting and lowering; it is controlled by a foot switch for convenient operation. |

|

Fan |

9-26NO-3.55A-2.2KW customized centrifugal fan |

|

Cylinder |

AirTAC |

|

Air flotation system |

The surface of the countertop is evenly covered with 4mm air flotation holes, and a high-pressure fan provides airflow to float the glass on the table, making it easier for operators to move the glass. |

|

Basic parameters |

Power supply: 380V/50HZ/2.2KW; air pressure: 0.6~0.8MPa |

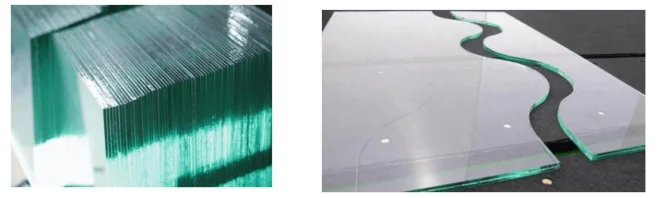

Cutting finished product type:

Functions & Features:

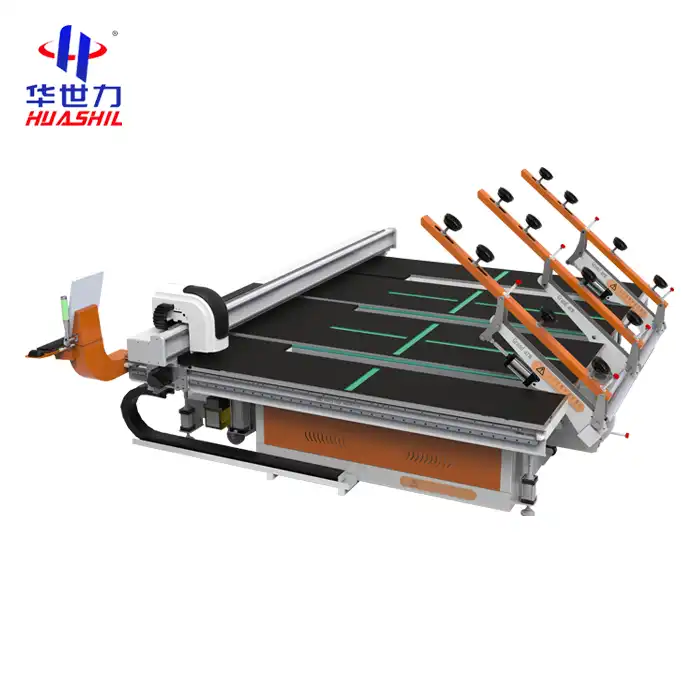

1.Cutting technology and automatic oil supply:

A:Professional glass cutting control system realizes automatic cutting of straight and special-shaped glass, greatly improving glass cutting efficiency.

B:The pressure of the cutting head is controlled by an electromechanical precision pressure valve. The uniform output pressure of the cylinder allows the cutting head to perfectly fit the glass surface for cutting, thus avoiding the cutting phenomenon caused by glass quality problems .

C:When cutting glass, the cutting oil is automatically filled using pneumatic pressure control, and moves synchronously with the cutting head through the PLC control system .

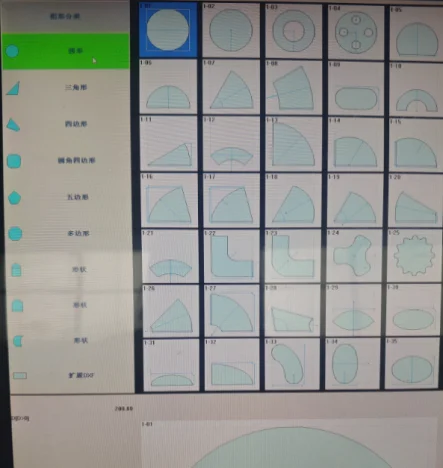

2.Optimization software and special-shaped libraries:

Compatible with the standard G code of Italian OPTIMA optimization software and domestic Guiyou software: achieving versatility in processing files in different formats.

3.Automatic edge positioning and intelligent special-shaped scanning:

Automatic edge-finding and positioning of glass: Accurately detects the actual position and deflection angle of the glass, and automatically adjusts the cutting path of the cutter head to improve efficiency.

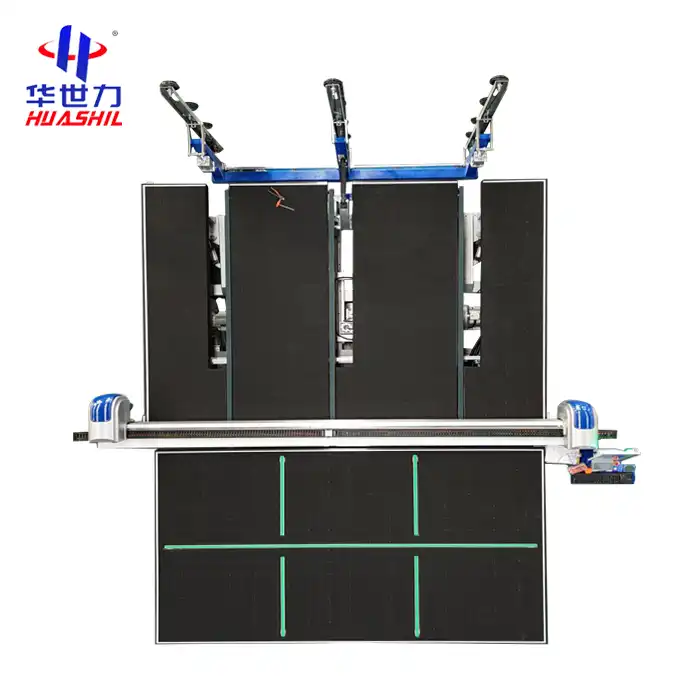

4.Telescopic boom and automatic loading:

Equipped with 3 big arms, each big arm is equipped with 4 sets of NBR suction cups to absorb glass, ensuring the stability and reliability of loading large glass sheets.

5.Air floating countertop:

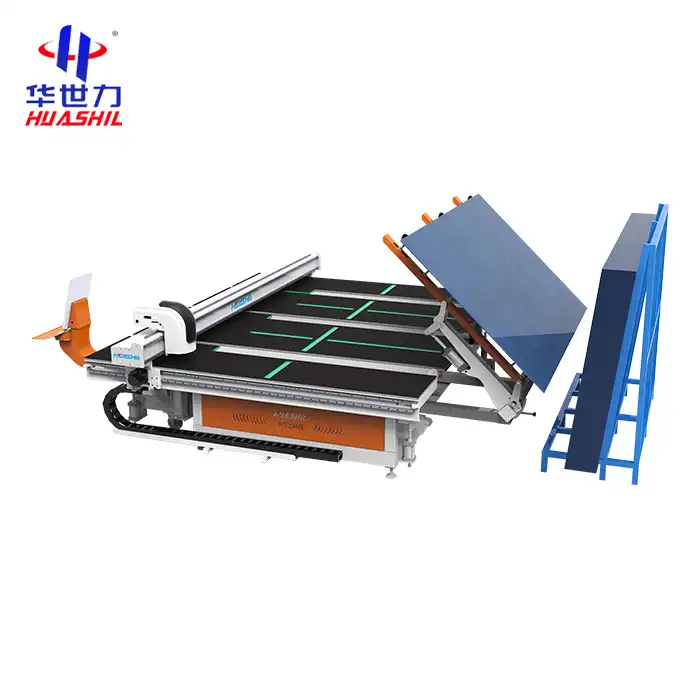

Cutting table and breaking table are equipped with air holes, and centrifugal fans provide high-pressure airflow to facilitate the transportation or shifting of glass while preventing scratches on the table.

6.Glass conveying:

After glass cutting, glass is transported to the air flotation breaking table through three synchronous conveying belts and the air flotation system for breaking operations.

7.Automatic labeling:

Replace manual labeling. The printer automatically prints out a label recording the glass information, and the fingers of the labeling cylinder grab the label and stick it on the surface of the corresponding glass piece. The standard machine head for labeling has high labeling efficiency. (Customers are recommended to configure the labeling function )

Why Choose Our Glass Cutting Machine?

-

Mature R&D Team: Continuous innovation for cutting-edge performance

-

Original Factory Direct Pricing: Eliminate middleman markups

-

10+ Years Export Experience: Trusted by global clients

-

Complete Certifications: CE, ISO9001 compliant for quality assurance

-

Smart Factory Solutions: Real-time data monitoring boosts yields

-

Fast Delivery: Streamlined production ensures timely shipment

-

OEM Support: Custom configurations to match your production needs

Key Features & Advantages

-

Automatic Loading System: Reduces manual handling and labor costs

-

Precision Pressure Control: Ensures clean cuts for 2-19mm glass thickness

-

360° Remote Control: Convenient operation from any position

-

Air Flotation System: Protects glass surfaces during processing

-

Ejector Rod Design: Enhances safety and material handling

-

Optima Optimization Software: Maximizes material utilization

-

Large Cutting Capacity: Handles sheets up to 3660×2800mm

Product Parameters:

| Feature | Specification |

|---|---|

| Cutting Speed | Up to 200 m/min |

| Maximum Glass Thickness | 3 - 19 mm |

| Cutting Precision | ±0.2 mm |

| Power Supply | 380V, 50Hz |

| Control System | CNC with touch screen |

| Dimensions | Customizable |

| Weight | Approximately 3100 kg |

Product Details:

Our HSL-CNC3829 glass sheet cutting machine is designed for precision and efficiency in furniture cabinet glass production. Its advanced features ensure clean, accurate cuts for various glass types and thicknesses. The machine's robust construction and user-friendly interface make it ideal for high-volume production environments.

Quality Control:

At Huashil Machine, we maintain rigorous quality standards throughout the manufacturing process. Each furniture cabinet glass cutting machine undergoes thorough testing and inspection before shipment. We provide mechanical test reports to ensure your complete satisfaction and confidence in our products.

Customization Options:

We understand that every production line is unique. Our team can customize the HSL-CNC3829 glass sheet cutting machine to meet your specific requirements, including color preferences and additional features to enhance your workflow.

Certification:

Our products are CE and ISO9001 certified, demonstrating our commitment to safety, quality, and international standards.

After-Sales Service:

Huashil Machine offers comprehensive after-sales support, including remote troubleshooting, on-site maintenance, and spare parts supply. Our professional team ensures minimal downtime and maximum productivity for your operations.

Packaging:

We use sturdy, protective packaging to ensure your product arrives in perfect condition. Our logistics team carefully handles every shipment to prevent damage during transit.

Company Introduction:

Huashil Machine is a trusted name in the glass processing industry, known for our innovative solutions and customer-centric approach. Our state-of-the-art factory and experienced team are dedicated to delivering top-quality machinery to clients worldwide.

FAQ:

Q: What types of glass can the HSL-CNC3829 cut?

A: It's suitable for architectural, coated, automotive, insulating, furniture, bathroom, decorative, solar, and cabinet glass.

Q: Do you offer installation services?

A: Yes, we provide professional installation and training services for our furniture cabinet glass cutting machine.

Q: What is the warranty period?

A: We offer a standard one-year warranty, with extended options available.

Q: Can I see the machine in operation before purchasing?

A: Absolutely! We provide video factory inspections upon request.

Q: How long is the delivery time?

A: Delivery times vary based on your location, but we strive for the fastest possible turnaround.

Contact Us:

Ready to revolutionize your furniture cabinet glass cutting process? Contact our sales team at salescathy@sdhuashil.com to learn more about our HSL-CNC3829 glass sheet cutting machine and how it can benefit your business.

YOU MAY LIKE

-

VIEW MOREMobile glass cutting machine

VIEW MOREMobile glass cutting machine -

VIEW MORECnc glass cutting equipment

VIEW MORECnc glass cutting equipment -

VIEW MORE3826 glass cutting machine

VIEW MORE3826 glass cutting machine -

VIEW MOREAutomatic glass breaking machine

VIEW MOREAutomatic glass breaking machine -

VIEW MORECnc mirror cutting machine

VIEW MORECnc mirror cutting machine -

VIEW MOREMirror loading and cutting machine

VIEW MOREMirror loading and cutting machine -

VIEW MOREGlass cutting table

VIEW MOREGlass cutting table -

VIEW MORE3829 glass cutting machine

VIEW MORE3829 glass cutting machine