These days' industrial glass cutters, like the commercial glass cutting machine, have precise control systems, can load glass automatically, and come with advanced optimization software that speeds up production a great deal. Cutting algorithms powered by AI and traditional mechanical precision have been combined by top manufacturers to get accuracy rates of more than 99.8%. Between 2 mm and 25 mm thick glass can be used with these machines. The edge quality stays the same for all types of glass, including laminated, Low-E coated, and tempered glass. High-tech conveyor systems and automated positioning mean that up to 75% less work needs to be done by hand. To stay competitive, manufacturing companies that want to cut costs and boost productivity need to make these investments.

How to Pick the Best Tools for Cutting Glass at Work?

You need to carefully think about a number of important things in order to choose the right equipment. Capacity to make things is the most important thing because machines need to be able to handle high demand without lowering quality. The thickness of the glass affects how flexible it is. For most industrial uses, the thickness needs to be between 2 and 19 mm. How much work needs to be done and how much it costs in the long run all depend on how much work needs to be done.

How accurate a product is has a direct effect on how well it works and how happy customers are with it. Look for machines that can keep a ±0.1mm tolerance all the time. The better nesting and material optimization are when software is integrated. This cuts down on waste and raises profits. Support after the sale makes sure that there isn't too much downtime while repairs or maintenance are done.

For installations that span borders, being a part of a regional service network is a must. Putting a CE mark or ISO compliance on a piece of equipment is one way to make sure that it is safe and follows all the rules. The total cost of owning a machine over its useful life should include the cost of setting it up, training people how to use it, maintenance, and spare parts.

Top 5 Commercial Glass Cutting Machines for 2025

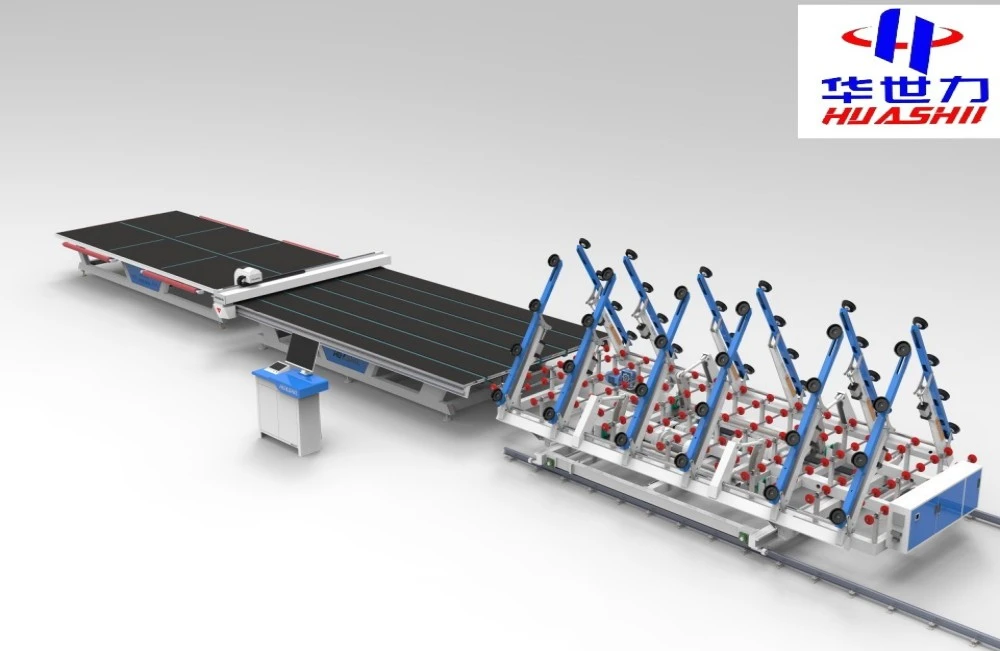

1. HUASHIL HSL-YTJ3826 Low-E Glass Cutting System

The HSL-YTJ3826 represents cutting-edge automation technology specifically designed for modern glass fabrication facilities. This system handles maximum glass dimensions of 3660×2440mm while accommodating thickness ranges from 2-19mm, making it ideal for architectural and furniture applications.

Key Features and Capabilities:

- Automatic loading system eliminates manual handling, improving safety and efficiency

- Precision pressure control maintains consistent cutting force across varying glass types

- Automated edge detection ensures optimal positioning for maximum material utilization

- Air flotation system provides smooth glass movement without surface damage

- Integrated breaking table completes the cutting process in one seamless operation

- 360-degree remote control enables safe operation from optimal vantage points

- Low-E film removal capability handles specialized architectural glass requirements

The Optima optimization software maximizes material efficiency by calculating optimal cutting patterns. Synchronous belt conveying systems ensure smooth glass transportation throughout the process. CE certification and ISO9001 compliance demonstrate adherence to international quality standards.

This commercial glass cutting machine excels in high-volume production environments where consistency and reliability are paramount. The combination of automation features reduces labor requirements while maintaining exceptional cut quality. Installation footprint of 5930×5100mm fits most manufacturing facilities without extensive modifications.

2. Advanced Multi-Layer Glass Processing Center

Multi-layer processing centers revolutionize production efficiency by handling multiple glass sheets simultaneously. These systems feature precision stacking mechanisms and coordinated cutting heads that maintain accuracy across all layers.

Technical Advantages:

- Simultaneous processing of up to 8 glass sheets reduces cycle times dramatically

- Independent pressure control for each layer ensures consistent cutting quality

- Advanced vibration dampening prevents resonance between cutting operations

- Automated separation systems organize cut pieces for efficient downstream processing

- Integrated quality monitoring detects variations and adjusts parameters automatically

- Modular design allows capacity expansion as production demands increase

The sophisticated control system coordinates multiple cutting heads while maintaining precise positioning accuracy. Smart sensors monitor cutting force and automatically adjust parameters to compensate for material variations. This technology particularly benefits curtain wall manufacturers processing large quantities of identical pieces.

Energy efficiency improvements reduce operational costs while environmental monitoring systems ensure compliance with modern manufacturing standards. The machine's flexibility accommodates various glass types and thicknesses without lengthy setup procedures.

3. High-Speed Automotive Glass Cutting Machine

Automotive applications demand exceptional precision and repeatability due to safety requirements and tight integration tolerances. Specialized machines address these needs with enhanced accuracy and automotive-specific features.

Specialized Capabilities:

- Curved cutting capability handles complex automotive glass shapes with precision

- Temperature-controlled cutting environment prevents thermal stress in processed glass

- Multi-axis positioning systems achieve complex geometries in single setups

- Automated quality inspection verifies dimensions against automotive standards

- Rapid tool changing systems minimize downtime between different part configurations

- Integration with automotive MES systems enables seamless production tracking

Advanced servo systems provide positioning accuracy within 0.05mm tolerances required for automotive applications. The machine handles various automotive glass types including windshields, side windows, and rear glass panels. Specialized tooling accommodates laminated glass processing without delamination.

Production rates exceed 150 pieces per hour while maintaining consistent quality standards. Automated handling systems protect delicate glass surfaces during processing and transfer operations.

4. Compact Glass Cutting Solution for Medium Production

Medium-scale manufacturers require efficient solutions that balance capability with investment costs. Compact systems deliver essential automation features while maintaining affordability for growing businesses.

Balanced Features:

- Space-efficient design fits smaller manufacturing facilities without compromising functionality

- Modular automation allows graduated capability increases as production grows

- Simplified operation reduces training requirements for production staff

- Cost-effective maintenance programs minimize long-term operational expenses

- Flexible programming accommodates diverse product requirements efficiently

- Standard industry interfaces enable integration with existing production systems

The commercial glass cutting machine control system provides intuitive operation while maintaining professional-grade precision and repeatability. Material handling automation reduces manual labor requirements without requiring extensive facility modifications. This solution particularly appeals to furniture manufacturers and small architectural glass processors.

Upgrade pathways allow capacity expansion without replacing core machinery components. The system's versatility handles both standard and specialty glass types effectively.

5. Heavy-Duty Industrial Glass Processing Line

Large-scale operations require robust machinery capable of continuous operation under demanding conditions. Heavy-duty systems provide maximum throughput while maintaining exceptional reliability.

Industrial-Grade Features:

- Reinforced construction handles maximum glass sizes up to 6000×3000mm dimensions

- Continuous operation capability supports 24/7 production schedules reliably

- Redundant safety systems ensure operator protection during all operating conditions

- Predictive maintenance monitoring prevents unexpected downtime through early detection

- High-capacity material handling accommodates large production volumes efficiently

- Environmental controls maintain optimal operating conditions regardless of facility conditions

The system integrates seamlessly with upstream and downstream processing equipment to create complete production lines. Advanced scheduling software optimizes production sequences to minimize setup times and maximize throughput.

Remote monitoring capabilities enable real-time performance tracking and immediate response to any operational issues. This technology serves large architectural glass manufacturers and major curtain wall fabricators requiring maximum production capacity.

Regional Market Analysis and Considerations

Southeast Asia Market Characteristics

Southeast Asian markets emphasize cost-effectiveness and rapid deployment capabilities. The region's growing construction sector drives demand for efficient glass processing equipment. Local regulations often require specific safety certifications and environmental compliance measures.

Humidity control becomes critical in tropical climates, affecting both machine operation and glass quality. Equipment must withstand environmental challenges while maintaining precision. Local service support networks are essential for timely maintenance and repairs.

Training programs gain importance due to varying technical education levels among operators. Simplified operation interfaces and comprehensive documentation support successful implementation across diverse manufacturing environments.

Russian Federation Requirements

Russian markets prioritize durability and cold-weather operation capabilities. Equipment must function reliably in extreme temperature variations while maintaining precision standards. Import certification processes require thorough documentation and compliance verification.

Local manufacturing preferences favor robust construction and simplified maintenance procedures. Energy efficiency considerations become more significant due to heating costs and environmental regulations. Technical support must accommodate language preferences and local engineering practices.

Payment terms often involve extended financing arrangements, making total cost of ownership calculations particularly important for purchasing decisions.

South American Market Dynamics

South American manufacturers focus on versatility and adaptability to handle diverse product requirements. Economic considerations emphasize maximum return on investment and flexible payment arrangements. Local content requirements may affect equipment sourcing and installation procedures.

Training and technical support become crucial success factors due to varying infrastructure levels across different countries. Equipment must accommodate power supply variations and environmental challenges specific to each location.

Regional service networks require careful planning to ensure adequate coverage across vast geographic distances. Spare parts availability directly impacts production continuity and customer satisfaction.

Middle East Considerations

Middle Eastern markets demand premium quality and advanced technology features. The region's construction boom drives requirements for high-capacity, reliable equipment. Environmental controls become critical in desert climates with extreme temperatures and dust conditions.

Cultural considerations affect training programs and operational procedures. Equipment, including the commercial glass cutting machine, must accommodate local engineering practices and maintenance preferences. Premium after-sales support justifies higher equipment investments common in this market.

Energy efficiency gains importance due to high electricity costs and environmental sustainability initiatives across the region.

How to Buy and Things You Should Think About?

You should think about what you need to make now and in the future before you buy the right tools. Discover how much it will cost to own the gear for as long as it is meant to last. This includes setting up, training, upkeep, and getting new parts. Be very careful about how much you automate, and weigh the cost savings from having less labor against the need to make an initial investment.

Check out the supplier's credentials, such as how well they can help with technical issues and how big and far their regional service networks reach. Make sure what the company says is true by calling past customers and visiting the facility. Ask for specifics on how the product will work. As your company grows, you should make sure that the systems you already have in place will still work.

Talk about courses that teach people how to fix, maintain, and use things. It's important to be clear about the warranty terms and when spare parts will be shipped. There are many ways to get money that will help your business grow and keep its cash flow in check.

So that they don't get in the way of work too much, plan when the installations will happen. The building will then be ready. Before the dates of delivery, make sure you have things like power, compressed air, and environmental controls.

Trends in the Industry and the Future

More automation and smart manufacturing integration are being added to the glass cutting industry all the time. Machine learning and artificial intelligence make cutting optimization and predictive maintenance better. Industry 4.0 connectivity lets you monitor and analyze production in real time from afar. Environmental sustainability leads to the creation of systems that use less energy and produce less waste. Because of these trends, companies that want to be competitive in the manufacturing world and have long-term success in demanding global markets need to invest in advanced glass cutting technology.

Conclusion

To choose the best commercial glass cutting machine, you need to carefully think about your long-term business goals, production needs, and technical abilities. The featured systems are tried-and-true options that work very well in a wide range of manufacturing settings. Investing in advanced automation technology gives a business a competitive edge by increasing quality, decreasing costs, and increasing efficiency. Taking into account regional markets is important for a successful implementation, and having full support from suppliers is essential for long-term success. In this fast-changing world of technology, it's important to work with well-known manufacturers who have shown they are knowledgeable, reliable, and dedicated to customer success.

Something a lot of people ask

1. How often should I fix and clean my business glass-cutting machines?

The machine is kept in good shape by oiling the moving parts once a week and cleaning the cutting edges every day. Each year, all the mechanical and safety systems are checked, and every month, the accuracy is checked to make sure it stays high. Most manufacturers say you should wait between 200 and 400 hours to avoid big problems. What the weather is like where you live and how often you use it.

2. How do I figure out what size business machine I need?

A: Think about how much money you have now and how much you think it will grow in three to five years. It's better to have machines than people when a lot of people want the same thing. Most manufacturers say that the maximum capacity of a piece of equipment should be 125 to 150% of its current peak capacity. This way, it can grow with your business and you can keep going while it's being fixed.

3. What kind of training do people who work as operators and maintenance workers need?

A person learns how to use a machine, follow safety rules, and fix simple problems in the first 40 to 60 hours of training. People who work in maintenance need more training on how to set up software, do complex diagnostics, and fix mechanical systems. Most suppliers have places where you can get trained and then help out on-site during the early stages of production as part of a full program.

Work with HUASHIL for the Best Glass Cutting Services

HUASHIL stands as your trusted commercial glass cutting machine supplier, delivering cutting-edge automation technology backed by years of manufacturing excellence. Our HSL-YTJ3826 system shows how committed we are to innovation. It has advanced Low-E film removal features and full automation that makes production much more efficient.

Shandong Huashil Automation Technology Co., LTD's reliable solutions can be found in Southeast Asia, Russia, South America, and the Middle East. They combine a lot of research and development knowledge with tried-and-true manufacturing skills. Our cutting-edge methods guarantee consistent quality, and our top-notch customer service guarantees the success of your investment.

See how professional engineering and dedicated customer service can make a difference in your manufacturing operations. Our team offers full advice, custom solutions, and ongoing technical support to help you get the most out of your equipment and make the most money.

Are you ready to improve your glass processing skills? Get in touch with our experts right away to talk about your specific needs and find out how HUASHIL technology can help you make your production more efficient. Get in touch with us at salescathy@sdhuashil.com for full technical details and personalized suggestions.