There are a lot of new professional glass cutting machines on the market in 2025. These machines give businesses more options than ever before for accuracy and automation. The strict needs of the glass fabrication, curtain wall systems, and furniture manufacturing industries around the world are now met by leading manufacturers who offer cutting-edge solutions such as CNC technology, advanced optimization software, and strong mechanical design.

Why factory technology for cutting glass is more important than ever?

To stay ahead of the competition in the glass processing business today, you need to be able to make things more quickly and easily. These days, building projects need to be more accurate, finish faster, and have consistent quality. Cutting things by hand doesn't meet these needs. Industrial glass cutters used to be simple scoring tools, but now they are automated systems that can handle many types of glass, complicated shapes, and large amounts of work.

Because they have smart software, precise mechanics, and easy-to-use screens, these machines are a must-have for plant managers who want to keep quality high while cutting down on labor costs. Increasingly, production directors in Southeast Asia, Russia, South America, and the Middle East understand that putting money into high-tech automation for cutting glass directly leads to more money and better market competition.

Things you should look for in sharp glass-cutting tools

You need to think about a lot of technical and business factors to find the best glass cutting machine. Dependability of the machine is the most important thing to think about because delays in production can cause delivery times to slip and customers to be unhappy. Engineering managers always put more weight on equipment that has been tested and shown to be stable when it is used all the time.

The needs of a project can be met by a machine that can make enough things and cut them accurately. A professional glass cutting machine is different from regular cutting tools because it can handle large panels of glass of different thicknesses and keep the quality of the edges the same over long production runs. Also, service after the sale is very important for buyers from other countries who need quick technical help and a steady supply of spare parts.

The total cost of ownership includes the price of the machine itself, the cost of setting it up, the cost of training operators, and the cost of regular upkeep. Smart people in charge of buying things don't just look at the upfront costs; they look at all of these things together. It's also important to have options for customization, especially for system integrators who need solutions that are made to fit their needs.

HUASHIL HSL-LSX6133: Cutting System with Advanced Multi-Station

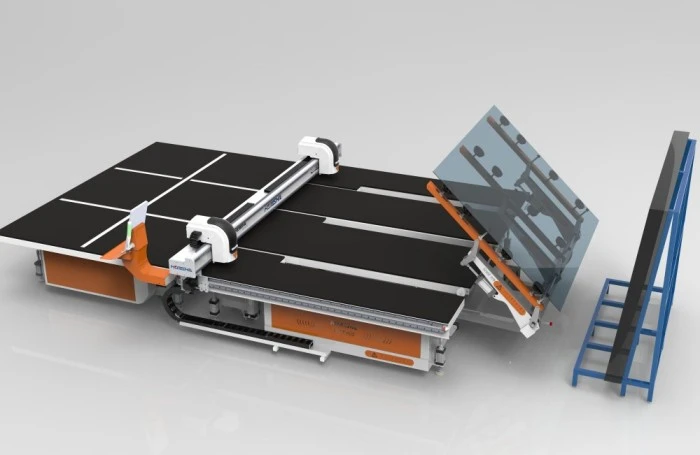

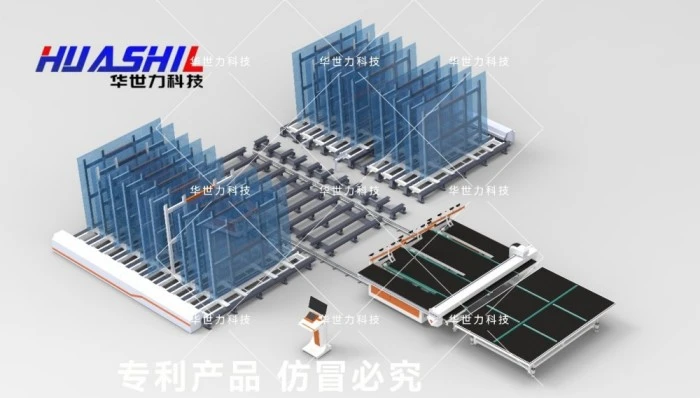

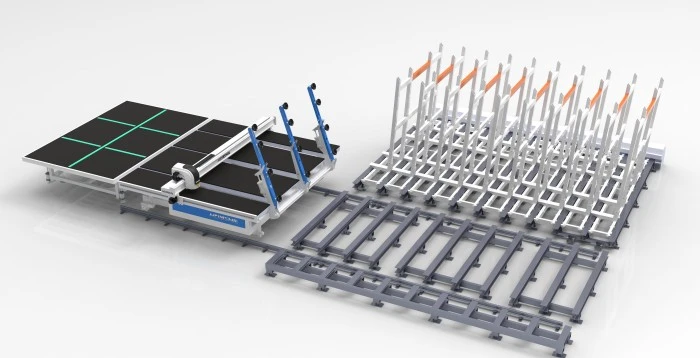

The HSL-LSX6133 is a big step forward in automated glass processing technology. It was made for industrial uses with a lot of glass. The three tables in this high-tech system—one for loading, one for cutting, and one for breaking—work together perfectly to make production as efficient as possible. Plant managers like this design because it gets rid of the problems that come with single-table systems.

Some important details are:

- The biggest glass size that can fit is 6100mm x 3300mm.

- A flexible 2+2 station system for an above- and underground rail system

- Each side has six grand arms for better glass handling.

- Optima optimization software built in to cut down on material waste

- A precise CNC cutting head that can change tools automatically

- Advanced safety systems with emergency stops and barriers to keep people safe

This machine is different from other cutting systems because it includes Optima software. This smart program looks at glass sheets and figures out the best way to cut them so that there is the least amount of waste and the most yield. Engineering teams say they've saved a lot of money, and the software investment is usually paid back in the first year of use. The easy-to-use interface lets operators quickly enter job requirements and automatically get cutting layouts that are best for them.

Because it is easy to install, the HSL-LSX6133 can be used in a variety of factory layouts. The configurable rail system can be added to existing production lines without making major changes to the building. This flexibility is especially helpful for manufacturers who want to grow their business or add new equipment to existing processes.

Precision CNC Solutions for Cutting Glass

Computer numerical control (CNC) has changed how accurate and consistent glass cutting is. Modern CNC glass cutters, including the professional glass cutting machine, can make tolerances that were previously impossible to achieve by hand. This lets manufacturers meet strict architectural requirements and lower rejection rates. These systems are great at making the complicated shapes, curved cuts, and intricate patterns that modern building designs call for.

Modern CNC systems have feedback systems that work in real time to keep an eye on cutting pressure, blade condition, and the quality of the glass surface. This constant monitoring stops problems before they happen, so the quality of the output stays the same throughout production runs. Technical managers like these systems because they make workers more productive while lowering the level of skill needed by operators.

Multi-axis cutting lets you polish and bevel the edges at the same time, so you don't have to do any extra work. This integration cuts down on handling time, lowers the risk of damage, and speeds up the order fulfillment process. These wide-ranging processing options are especially helpful for companies that work with expensive architectural glass.

Automated lines for processing glass

The most advanced glass cutting technology is complete automation systems, which combine moving materials, cutting, breaking, and packaging into single production lines. These systems greatly reduce the amount of work that needs to be done while reaching throughput rates that have never been seen before. Large manufacturers often say that the big investment is worth it because it increases efficiency and lowers operating costs.

Artificial intelligence algorithms are built into modern automated lines. These algorithms learn from production patterns and keep improving performance. Machine learning lets you plan maintenance ahead of time, which cuts down on unexpected downtime and makes equipment last longer. After putting these intelligent systems in place, production directors say that the overall effectiveness of their equipment has improved by a large amount.

Even in systems with a lot of automation, flexibility is still very important. The best manufacturers make their automation lines so that they can handle different types, thicknesses, and sizes of glass without having to go through long changeover processes. Because they are so flexible, manufacturers can quickly adapt to changing customer and market needs.

Analysis of the regional market and consumer tastes

In Southeast Asian markets, buyers want equipment that has both advanced features and a low initial cost. In this area, manufacturers often choose modular systems that let them add more automation as their businesses grow. Local laws are putting more and more emphasis on safety at work, which is increasing the demand for machines with full safety systems and features that protect the operator.

Russian industrial buyers usually care about how long equipment lasts and how well it works in cold weather. The harsh weather means that mechanical systems and heating systems must be strong and reliable so that they can be used all year. In this market, buyers are often influenced by longer warranty terms and complete spare parts packages.

South American manufacturers like working with equipment suppliers that have large networks of local support staff. Language issues, cultural familiarity, and quick technical help all play a big role in choosing a supplier. A lot of buyers in this area like payment terms that are spread out over time so that they can fit with project milestones and cash flow cycles.

Middle Eastern markets put a lot of value on cutting-edge technology and high levels of automation. The big building projects in the area need tools that can work with large glass panels and complicated geometric shapes, making a professional glass cutting machine a key choice. Because of environmental rules and rising power costs, saving energy has become more important.

Purchasing Recommendations and Key Considerations

Successful equipment acquisition requires thorough evaluation of current production needs and future growth projections. Plant managers should assess their typical glass sizes, processing volumes, and quality requirements before selecting specific machine configurations. Oversizing equipment capabilities provides flexibility but increases costs, while undersizing limitations may constrain future business opportunities.

Supplier evaluation extends beyond machine specifications to encompass technical support capabilities, training programs, and long-term partnership potential. Manufacturers benefit from suppliers who understand their specific applications and can provide customization when needed. Reference installations and customer testimonials offer valuable insights into real-world performance and reliability.

Installation planning and operator training significantly impact project success. Comprehensive training programs ensure operators can fully utilize machine capabilities while maintaining safety standards. Suppliers who provide detailed installation support and ongoing technical assistance typically deliver better long-term value despite potentially higher initial costs.

Industry Trends and Summary

The glass cutting industry continues embracing digitalization, artificial intelligence, and sustainable manufacturing practices. Smart factory integration, predictive maintenance, and energy-efficient operation have become standard expectations rather than premium features. Manufacturers who invest in modern glass cutting automation position themselves for sustained competitiveness in an increasingly demanding marketplace. The convergence of precision engineering, intelligent software, and user-friendly operation creates unprecedented opportunities for productivity improvement and quality enhancement.

Conclusion

When looking for the best professional glass cutting machine, you need to think about its technical specs, how much it will cost, and how long it will last. The HSL-LSX6133 and other advanced systems like it show how modern automation technology can adapt to the changing needs of glass manufacturers around the world. To be successful, you need to work with suppliers who have been in the business for a while and know both the technical needs and the business side of industrial glass processing. Investing in cutting technology that has been shown to work brings clear benefits like higher quality, higher efficiency, and lower costs for a wide range of manufacturing uses.

Frequently Asked Questions

Q1: What maintenance requirements should I expect with professional glass cutting machines?

A: Professional glass cutting equipment typically requires daily cleaning, weekly lubrication of moving parts, and monthly calibration checks. Most manufacturers recommend professional maintenance service every 6-12 months depending on usage intensity. Blade replacement frequency varies based on glass types processed, but quality cutting heads often last 3-6 months under normal industrial use.

Q2: How long does installation and operator training typically take?

A: Standard machine installation usually takes 5-10 days including mechanical setup, electrical connections, and initial calibration. Operator training programs range from 3-7 days depending on system complexity and operator experience levels. Advanced automation systems may require 2-3 weeks for complete installation and commissioning.

Q3: What glass thickness ranges can modern cutting machines handle?

A: Professional glass cutting machines typically process glass from 2mm to 25mm thickness, with specialized equipment capable of handling up to 40mm for architectural applications. The HSL-LSX6133 efficiently processes standard architectural glass thicknesses while maintaining precise edge quality across the entire range.

Partner with HUASHIL for Advanced Glass Cutting Solutions

HUASHIL delivers comprehensive glass cutting automation that transforms manufacturing efficiency and product quality. Our HSL-LSX6133 professional glass cutting machine represents years of engineering excellence and real-world application refinement. As a trusted glass cutting machine manufacturer, we understand the unique challenges facing architectural glass fabricators, curtain wall integrators, and furniture manufacturers across diverse international markets.

Our technical team provides personalized consultation to ensure equipment specifications align perfectly with your production requirements and growth objectives. From initial concept through installation and ongoing support, HUASHIL maintains unwavering commitment to customer success. Contact us at salescathy@sdhuashil.com to discuss how our advanced glass cutting technology can elevate your manufacturing capabilities and competitive position.

References

1. Glass Manufacturing Industry Association. "Industrial Glass Processing Technology Standards and Best Practices." Annual Technical Report, 2024.

2. International Council on Glass Processing. "Automation Trends in Architectural Glass Manufacturing." Industry Survey Results, 2024.

3. Smith, Michael R. "Advanced CNC Glass Cutting: Precision and Efficiency in Modern Manufacturing." Industrial Automation Quarterly, Vol. 15, 2024.

4. European Glass Technology Institute. "Safety Standards for Industrial Glass Cutting Equipment." Technical Bulletin 2024-03.

5. Rodriguez, Carlos and Ahmed Hassan. "Regional Market Analysis: Glass Processing Equipment in Emerging Markets." Global Manufacturing Review, 2024.

6. Asian Glass Manufacturers Federation. "Optimization Software Integration in Glass Cutting Systems." Technical Conference Proceedings, 2024.