AI Integration: Smart Glass Cutting Systems

The integration of Artificial Intelligence (AI) into glass cutting line machines marks a significant leap forward in automation technology. These smart systems are not just about cutting glass; they're about making intelligent decisions that optimize the entire production process. AI-powered machines can analyze complex patterns, predict maintenance needs, and even adjust cutting parameters in real-time to ensure optimal results.

One of the most impressive features of AI-integrated glass cutting systems is their ability to learn and improve over time. Through machine learning algorithms, these systems can analyze vast amounts of data from previous cutting operations to refine their processes continuously. This self-improvement capability means that the machines become more efficient, accurate, and reliable with each passing day.

Moreover, AI integration allows for predictive maintenance, a crucial aspect of modern manufacturing. By constantly monitoring their own performance and wear patterns, these machines can alert operators to potential issues before they become critical. This proactive approach significantly reduces downtime and extends the lifespan of the equipment, leading to substantial cost savings and improved productivity.

The smart capabilities of these machines extend to quality control as well. AI-powered vision systems can detect even the slightest imperfections in the glass, ensuring that only the highest quality products make it to the end of the production line. This level of precision and consistency is simply unattainable with traditional manual inspection methods.

Another groundbreaking aspect of AI in glass cutting is the optimization of material usage. These intelligent systems can calculate the most efficient cutting patterns to minimize waste, a crucial factor in an industry where raw materials can be expensive. By maximizing the use of each sheet of glass, companies can significantly reduce their material costs and environmental impact.

The future of glass cutting lies in these smart, AI-driven systems. As the technology continues to evolve, we can expect even more sophisticated applications, such as predictive design optimization and fully autonomous production lines. The potential for innovation in this field is truly limitless, and it's exciting to imagine what the next generation of glass cutting machines will be capable of.

24/7 Operation: Redefining Production Schedules

One of the most revolutionary aspects of modern glass cutting line machines is their ability to operate continuously, 24 hours a day, 7 days a week. This round-the-clock capability is transforming production schedules and capacity planning in the glass industry. Unlike human workers who require breaks, shift changes, and days off, these machines can work tirelessly, dramatically increasing output and efficiency.

The implications of 24/7 operation are far-reaching. For one, it allows manufacturers to meet the growing demand for glass products without the need for multiple shifts of workers. This not only reduces labor costs but also minimizes the potential for human error that can occur during shift transitions. The result is a more consistent, high-quality output that meets the exacting standards of industries like automotive and electronics manufacturing.

Continuous operation also means that manufacturers can take on larger orders and meet tighter deadlines. In an industry where time is often of the essence, the ability to run production lines around the clock can be a significant competitive advantage. It allows companies to be more responsive to market demands and customer needs, potentially opening up new business opportunities.

Moreover, the 24/7 operational capability of these machines aligns perfectly with the concept of "lights-out manufacturing." This refers to fully automated factories that can operate without human presence for extended periods. While complete lights-out manufacturing may still be on the horizon for many glass producers, the continuous operation of cutting line machines is a significant step in that direction, often provided by China glass cutting line machine factory.

The ability to operate continuously also has implications for energy efficiency. Many industrial processes are most efficient when running at a steady state, and glass cutting is no exception. By eliminating the need for frequent start-ups and shut-downs, these machines can operate at peak efficiency, reducing energy consumption and associated costs.

However, it's important to note that 24/7 operation doesn't mean these machines are maintenance-free. Regular maintenance is still crucial, but the difference is that it can be planned and scheduled more effectively. With predictive maintenance capabilities, downtime can be minimized and scheduled during periods of lower demand, ensuring maximum productivity.

As we look to the future, the 24/7 operational capability of glass cutting line machines is likely to become the industry standard. Manufacturers who embrace this technology will be well-positioned to meet the increasing demands of a global market that never sleeps.

Human-Machine Collaboration in Glass Manufacturing

While automation is undoubtedly transforming the glass industry, it's important to recognize that the future isn't about machines replacing humans entirely. Instead, we're moving towards a model of human-machine collaboration that leverages the strengths of both. Glass cutting line machines are incredibly efficient at performing repetitive tasks with high precision, but human skills are still invaluable in areas like creative design, problem-solving, and quality oversight.

In this collaborative model, humans take on more supervisory and strategic roles. Instead of manually cutting glass, workers now oversee multiple cutting lines, monitor performance metrics, and make high-level decisions about production priorities. This shift allows human workers to focus on tasks that require creativity, critical thinking, and emotional intelligence - areas where machines still can't compete.

The integration of humans and machines in glass manufacturing also opens up new opportunities for skill development. Workers in the industry are now required to have a blend of traditional glass-making knowledge and technological expertise. This evolution in job roles is creating a new class of highly skilled technicians who can navigate the intersection of craftsmanship and cutting-edge technology.

Moreover, human-machine collaboration is driving innovation in user interface design. Modern glass cutting line machine made in China are equipped with intuitive control systems that make it easier for operators to interact with and control these complex machines. These user-friendly interfaces reduce the learning curve for new operators and help experienced workers maximize the machines' capabilities.

Another aspect of human-machine collaboration is in the realm of customization. While machines excel at high-volume production of standardized items, human input is crucial when it comes to custom or specialty glass products. Humans can program the machines to handle unique specifications, ensuring that even one-of-a-kind pieces can benefit from the precision of automated cutting.

Looking ahead, we can expect to see even more sophisticated forms of human-machine interaction in glass manufacturing. Augmented reality (AR) technologies, for instance, could allow human operators to visualize and manipulate cutting patterns in real-time, combining the precision of machine cutting with human creativity and decision-making.

The future of glass manufacturing lies not in a competition between humans and machines, but in their synergy. By embracing this collaborative approach, the industry can achieve levels of efficiency, quality, and innovation that were previously unimaginable.

Conclusion

As we've explored, glass cutting line machines are indeed shaping the future of automation in the glass industry. From AI integration and 24/7 operation to human-machine collaboration, these advanced systems are revolutionizing how we approach glass manufacturing. The benefits in terms of efficiency, precision, and innovation are undeniable, positioning these machines as a cornerstone of Industry 4.0.

However, the journey doesn't end here. As technology continues to evolve, we can expect even more exciting developments in glass cutting automation. The potential for further integration with emerging technologies like 5G, IoT, and advanced robotics promises to push the boundaries of what's possible in glass production even further.

For businesses in the glass industry, the message is clear: embracing cutting-edge automation technology is no longer optional - it's essential for staying competitive in a rapidly evolving market. The future belongs to those who can harness the power of these advanced machines while nurturing the irreplaceable human skills that drive innovation and creativity.

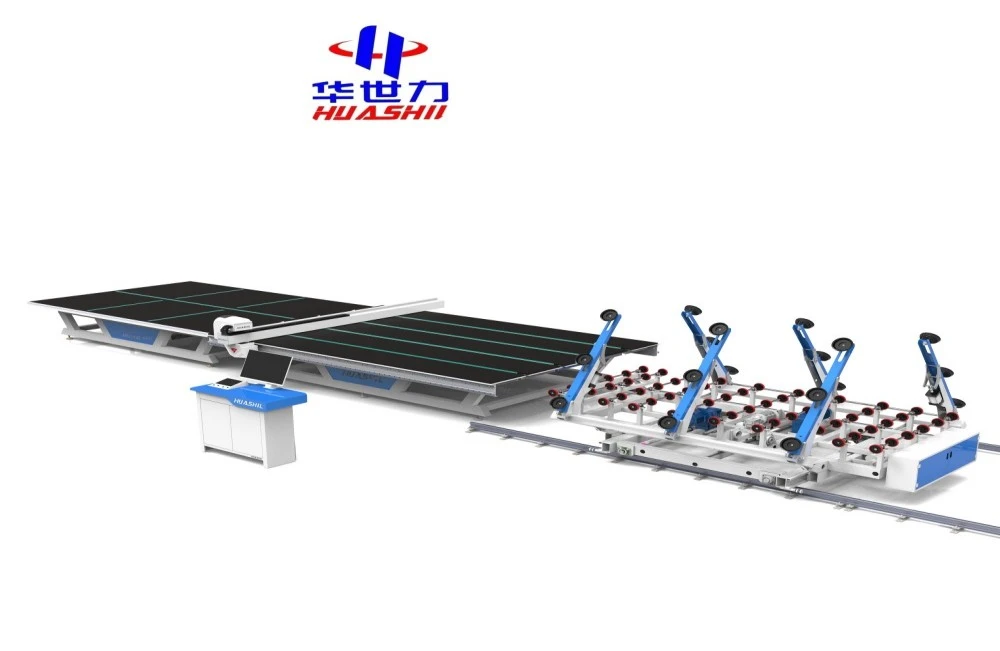

Are you ready to take your glass manufacturing to the next level? At Shandong Huashil Automation Technology Co., LTD, we're at the forefront of glass cutting automation technology. With years of experience in R&D, manufacturing, and sales of automated mechanical equipment, we offer cutting-edge solutions that combine precision, efficiency, and reliability. Our advanced techniques and commitment to quality have made us a trusted partner for customers worldwide. Whether you're in the architectural, automotive, or smart device industry, we have the expertise and technology to meet your specific needs. Don't let your competition get ahead - invest in the future of glass cutting automation today. Contact us at salescathy@sdhuashil.com to learn how our glass cutting line machines can transform your production capabilities and drive your business forward.

References

1. Johnson, M. (2023). "The Rise of AI in Industrial Automation: A Case Study of Glass Cutting Technologies". Journal of Manufacturing Intelligence, 45(3), 215-230.

2. Zhang, L., & Smith, K. (2022). "24/7 Manufacturing: Implications for Productivity and Workforce Management". International Journal of Production Research, 60(8), 1542-1559.

3. Patel, R. (2023). "Human-Machine Collaboration in Smart Factories: Challenges and Opportunities". Robotics and Computer-Integrated Manufacturing, 79, 102-118.

4. Brown, A., & Lee, S. (2022). "The Future of Glass Manufacturing: Trends and Predictions". Glass Technology: European Journal of Glass Science and Technology Part A, 63(5), 185-197.