In the world of precision glass manufacturing, CNC glass cutting machines have revolutionized the industry with their accuracy, efficiency, and versatility. At the heart of these sophisticated machines lies the cutting head, a crucial component that determines the quality and precision of the glass cuts. This article delves into the intricate workings of the cutting head, exploring its anatomy, the scoring process, and the control mechanisms that make it a marvel of modern engineering.

Anatomy of a CNC Glass Cutting Head

The cutting head of a CNC glass cutting machine is a complex assembly of various components, each playing a vital role in the cutting process. Let's break down the key elements:

Cutting Wheel

The cutting wheel, typically made of tungsten carbide or diamond, is the primary tool that comes into contact with the glass surface. Its shape and material composition are crucial for creating a clean, precise score line on the glass.

Wheel Holder

The wheel holder secures the cutting wheel in place and allows for easy replacement when necessary. It's designed to maintain the optimal angle of the cutting wheel relative to the glass surface.

Pressure Mechanism

A sophisticated pressure mechanism ensures that the cutting wheel applies the correct amount of force to the glass surface. This can be pneumatically or servo-controlled, allowing for precise adjustments based on the glass thickness and type.

Lubrication System

Many cutting heads incorporate a lubrication system that applies a thin film of cutting oil to the glass surface. This reduces friction, prolongs the life of the cutting wheel, and improves the quality of the score line.

Sensors

Advanced cutting heads are equipped with various sensors that monitor factors such as cutting force, wheel wear, and glass thickness. These sensors provide real-time feedback to the CNC control system, allowing for on-the-fly adjustments to maintain cutting quality.

The Scoring Process: Creating a Controlled Fracture Line

The cutting head's primary function in a CNC glass cutting machine is to create a score line on the glass surface. This score line serves as a controlled fracture point, allowing the glass to be cleanly separated along the desired path. Let's examine the steps involved in this precise process:

Initial Contact

As the cutting head approaches the glass, sensors detect the surface and adjust the head's height to maintain the optimal cutting angle. The cutting wheel makes initial contact with the glass at a precisely calculated point.

Pressure Application

The pressure mechanism applies a carefully controlled force to the cutting wheel. This force is crucial – too little pressure results in an inadequate score, while excessive pressure can cause undesired chipping or cracking.

Score Line Creation

As the cutting head moves along the programmed path, the rotating cutting wheel creates a microscopic fracture in the glass surface. This fracture typically penetrates about 10% of the glass thickness.

Lubrication

Simultaneously, the lubrication system dispenses a fine mist of cutting oil ahead of the wheel. This oil serves multiple purposes: it reduces friction, dissipates heat, and helps to propagate the microscopic fracture created by the cutting wheel.

Continuous Adjustment

Throughout the scoring process, the cutting head's sensors continuously monitor various parameters. The CNC system uses this data to make real-time adjustments to cutting speed, pressure, and lubrication, ensuring consistent quality across the entire cut.

Completion and Retraction

Once the score line is complete, the cutting head retracts, lifting the cutting wheel clear of the glass surface. The scored glass is then ready for the breaking process, where it will cleanly separate along the score line.

Pneumatic vs. Servo Control for Downward Pressure

The mechanism controlling the downward pressure of the cutting wheel is a critical factor in the performance of a CNC glass cutting machine. Two primary technologies are used in modern cutting heads: pneumatic control and servo control. Each has its advantages and considerations:

Pneumatic Control

Pneumatic systems use compressed air to regulate the pressure applied by the cutting wheel. Here are some key points about pneumatic control:

- Simplicity: Pneumatic systems are relatively simple, making them easier to maintain and repair.

- Cost-effective: Generally less expensive than servo-controlled systems.

- Speed: Can quickly adjust pressure, suitable for high-speed cutting operations.

- Limitations: May have less precise control over pressure variations compared to servo systems.

Servo Control

Servo-controlled systems use electric motors and advanced feedback mechanisms to regulate cutting pressure. Consider these aspects of servo control:

- Precision: Offers extremely accurate control over cutting pressure, allowing for fine adjustments.

- Consistency: Maintains highly consistent pressure throughout the cutting process.

- Flexibility: Can easily adapt to different glass thicknesses and types without manual adjustments.

- Data integration: Easily integrates with the CNC system for data logging and analysis.

- Cost: Generally more expensive than pneumatic systems, both in initial investment and maintenance.

Hybrid Systems

Some advanced CNC glass cutting machines employ hybrid systems that combine elements of both pneumatic and servo control. These systems aim to leverage the strengths of both technologies, offering a balance of simplicity, cost-effectiveness, and precision.

Choosing the Right Control System

The choice between pneumatic and servo control depends on various factors, including:

- Type of glass being cut (thickness, composition)

- Required cutting precision

- Production volume and speed requirements

- Budget constraints

- Maintenance capabilities

For high-precision applications or facilities cutting a wide variety of glass types, servo-controlled systems often provide the necessary flexibility and accuracy. However, for operations with more standardized cutting requirements, pneumatic systems can offer a cost-effective solution without sacrificing quality.

Future Trends in Cutting Head Technology

As technology continues to advance, we can expect to see further innovations in cutting head design for CNC glass cutting machines. Some potential developments include:

- Integration of artificial intelligence for predictive maintenance and automatic optimization of cutting parameters

- Advanced materials for cutting wheels that offer longer life and improved performance

- Enhanced sensor technology for even more precise control and monitoring

- Improved lubrication systems that reduce waste and environmental impact

These advancements will likely lead to even more efficient, precise, and versatile CNC glass cutting machines, further revolutionizing the glass manufacturing industry.

Conclusion

The cutting head is the unsung hero of CNC glass cutting machines, performing the crucial task of creating precise score lines that enable clean, accurate glass cuts. By understanding the anatomy of the cutting head, the intricacies of the scoring process, and the nuances of pressure control systems, we gain a deeper appreciation for the engineering marvels that make modern glass manufacturing possible.

As technology continues to evolve, we can expect cutting heads to become even more sophisticated, offering improved precision, efficiency, and versatility. These advancements will undoubtedly open up new possibilities in glass design and manufacturing, pushing the boundaries of what's possible in architecture, automotive design, and consumer electronics.

For those in the glass manufacturing industry, staying informed about these technological developments is crucial. By leveraging the latest advancements in CNC glass cutting technology, manufacturers can improve their production efficiency, reduce waste, and create higher-quality products that meet the ever-increasing demands of modern applications.

FAQ

1. What is the lifespan of a cutting wheel in a CNC glass cutting machine?

The lifespan of a cutting wheel can vary significantly depending on factors such as the type of glass being cut, the cutting speed, and the quality of the wheel itself. On average, a high-quality cutting wheel can last anywhere from 5,000 to 20,000 linear meters of cuts before requiring replacement.

2. Can CNC glass cutting machines handle curved or irregular shapes?

Yes, modern CNC glass cutting machines are highly versatile and can handle a wide range of shapes, including curved and irregular patterns. The precision of the cutting head, combined with advanced CNC control systems, allows for complex cutting paths to be executed with high accuracy.

3. How does glass thickness affect the cutting process?

Glass thickness is a crucial factor in the cutting process. Thicker glass generally requires more pressure from the cutting wheel and may necessitate multiple passes to create a deep enough score line. The CNC system adjusts parameters such as cutting speed, pressure, and lubrication based on the glass thickness to ensure optimal cutting results.

4. Are there different types of cutting wheels for various glass compositions?

Yes, cutting wheels come in various materials and designs optimized for different types of glass. For example, some wheels are specifically designed for cutting tempered glass, while others are better suited for laminated or low-E glass. Choosing the right cutting wheel for the specific glass type is essential for achieving the best cutting quality and wheel longevity.

CNC Glass Cutting Machine Manufacturers | HUASHIL

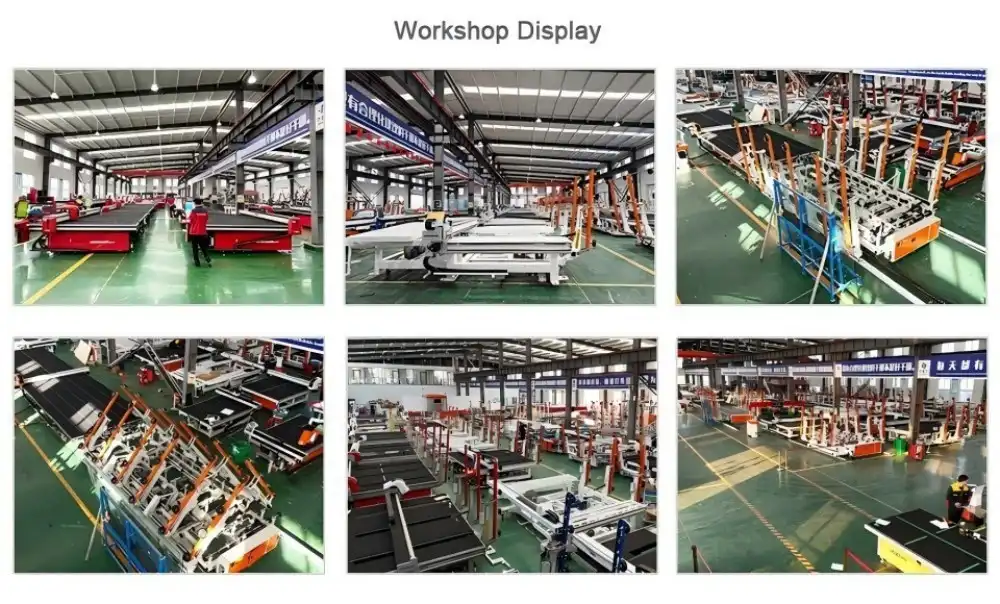

Looking for a reliable and innovative CNC glass cutting machine manufacturer? Shandong Huashil Automation Technology Co., LTD is your go-to solution for high-quality, precision glass cutting equipment. As a leading manufacturer in the industry, we offer a comprehensive range of CNC glass cutting machines designed to meet the diverse needs of our global clientele.

Our cutting-edge technology, coupled with years of manufacturing expertise, ensures that you receive machines that are not only efficient and accurate but also durable and easy to maintain. Whether you're in the architectural glass industry, automotive sector, or specialized glass manufacturing, our CNC glass cutting machines are engineered to elevate your production capabilities.

At Huashil, we understand that every customer has unique requirements. That's why we offer customized solutions tailored to your specific needs. Our team of experts is ready to work with you to design and implement the perfect glass cutting solution for your business.

Don't settle for less when it comes to your glass cutting needs. Choose Huashil for unparalleled quality, reliability, and after-sales support. Contact us today at salescathy@sdhuashil.com to discuss how we can help optimize your glass cutting operations and drive your business forward. Let Huashil be your partner in precision and innovation in the world of CNC glass cutting technology.

References

1. Johnson, A. (2022). Advanced Techniques in CNC Glass Cutting: A Comprehensive Guide. Journal of Glass Technology, 45(3), 112-128.

2. Smith, R. & Brown, T. (2023). Innovations in Cutting Head Design for Precision Glass Manufacturing. International Journal of Industrial Automation, 18(2), 87-103.

3. Zhang, L. et al. (2021). Comparative Analysis of Pneumatic and Servo-Controlled Pressure Systems in CNC Glass Cutting. Proceedings of the 9th International Conference on Manufacturing Engineering, 234-249.

4. Anderson, K. (2023). The Future of Glass Cutting: Emerging Technologies and Their Impact on Industry. Glass Processing Quarterly, 37(4), 56-72.