In today's competitive stone fabrication industry, staying ahead of the curve is crucial for success. One technology that has revolutionized the way stone fabrication shops operate is the CNC stone cutting machine. These advanced machines offer unparalleled precision, efficiency, and versatility, making them an invaluable asset for businesses looking to enhance their productivity and product quality. Let's explore the myriad benefits that CNC stone cutting machines bring to stone fabrication shops and how they can transform your operations.

How CNC Improves Shop Productivity and Quality?

The introduction of CNC technology in stone fabrication has brought about a paradigm shift in productivity and quality standards. Here's how:

- Automation of Complex Tasks: CNC machines can handle intricate cutting patterns and designs that would be challenging or impossible to achieve manually. This automation not only saves time but also ensures consistent quality across all cuts.

- Reduced Human Error: By minimizing manual intervention, CNC machines significantly reduce the likelihood of errors, leading to fewer mistakes and less material waste.

- Increased Output: With their ability to operate continuously and at high speeds, CNC machines can dramatically increase a shop's production capacity. This allows businesses to take on more projects and meet tighter deadlines.

- Improved Material Utilization: Advanced software used in CNC machines optimizes cutting patterns to maximize material usage, reducing waste and lowering material costs.

- Enhanced Finish Quality: The precision of CNC cutting results in smoother edges and more accurate dimensions, often eliminating the need for additional finishing work.

By leveraging these advantages, CNC stone cutting machine fabrication shops can significantly boost their productivity while maintaining high-quality standards. This combination of efficiency and quality is crucial for staying competitive in today's market.

Precision and Repeatability Advantages

The hallmark of CNC stone cutting machines is their unmatched precision and repeatability. These attributes bring several key advantages to stone fabrication shops:

- Micron-Level Accuracy: CNC machines can achieve cutting accuracies down to fractions of a millimeter, ensuring that every piece meets exact specifications.

- Consistent Results: Whether producing one piece or a thousand, CNC machines deliver the same high level of accuracy and quality every time. This consistency is invaluable for large-scale projects or repeat orders.

- Complex Designs Made Simple: Intricate patterns, curves, and 3D shapes that would be challenging to create manually become feasible with CNC technology. This opens up new design possibilities and allows shops to take on more diverse projects.

- Reduced Need for Rework: The high precision of CNC cutting minimizes errors and the need for adjustments or rework, saving time and materials.

- Customization Capabilities: CNC machines can easily switch between different cutting patterns and designs, allowing for efficient customization of products without significant setup time.

These precision and repeatability advantages not only improve the quality of the final product but also contribute to increased customer satisfaction and loyalty. Shops equipped with CNC stone cutting machine technology can confidently take on challenging projects, knowing they have the tools to deliver consistently excellent results.

Scaling Business with CNC Technology Adoption

Adopting CNC technology is not just about improving current operations; it's a strategic move that can facilitate significant business growth. Here's how CNC stone cutting machines can help scale your stone fabrication business:

- Increased Production Capacity: With their speed and efficiency, CNC machines allow shops to handle larger volumes of work without proportionally increasing labor costs.

- Diversification of Services: The versatility of CNC machines enables shops to expand their service offerings, potentially entering new markets or attracting a broader client base.

- Improved Competitiveness: The ability to produce high-quality work faster and more efficiently gives CNC-equipped shops a significant edge in bidding for projects.

- Enhanced Reputation: Consistently delivering precise, high-quality work helps build a strong reputation in the industry, leading to more referrals and repeat business.

- Scalable Workflow: CNC technology allows for easier scaling of operations. As demand grows, additional machines can be integrated seamlessly into existing workflows.

- Skill Development: Operating CNC machines requires specialized skills, elevating the overall skill level of your workforce and attracting talent interested in working with advanced technology.

- Data-Driven Improvements: Many CNC systems provide detailed operational data, allowing for continuous process improvement and optimization.

By leveraging these scaling opportunities, stone fabrication shops can transform their operations from small-scale workshops to efficient, high-capacity CNC stone cutting machine production facilities. This growth potential makes CNC technology an investment in the future of your business.

Conclusion

The adoption of CNC technology in stone fabrication is more than just a trend; it's becoming a necessity for shops looking to remain competitive and grow in an evolving market. From improving productivity and quality to enabling business scaling, the CNC stone cutting machine factory offers a wide range of benefits that can significantly impact your bottom line.

As the industry continues to advance, those who embrace this technology will find themselves well-positioned to meet increasing demands for precision, quality, and efficiency. Whether you're looking to streamline your current operations or preparing for future growth, investing in CNC technology could be the key to unlocking your shop's full potential.

FAQ

Q1: What types of stone can be cut with a CNC stone cutting machine?

A: CNC stone cutting machines are versatile and can cut a wide variety of stone materials, including granite, marble, limestone, sandstone, and engineered stone. The specific capabilities may vary depending on the machine model and the cutting tools used, but generally, these machines can handle most types of natural and man-made stone used in construction and decorative applications.

Q2: How does a CNC stone cutting machine compare to traditional manual cutting methods in terms of efficiency?

A: CNC stone cutting machines significantly outperform traditional manual cutting methods in terms of efficiency. They can operate continuously at high speeds, producing complex cuts with precision that would be difficult or impossible to achieve manually. While the initial setup time for a CNC machine might be longer, once programmed, it can replicate the same cut repeatedly without variation, dramatically increasing overall productivity. Additionally, CNC machines reduce material waste and the need for rework, further enhancing efficiency.

Q3: What level of training is required to operate a CNC stone cutting machine?

A: Operating a CNC stone cutting machine requires specialized training, but the level of expertise needed can vary depending on the complexity of the machine and the tasks performed. Typically, operators need to understand:

- Basic computer skills and CAD/CAM software operation

- Programming and operating the CNC machine

- Material properties and cutting techniques

- Safety procedures and machine maintenance

Many manufacturers offer training programs, and there are also vocational courses available. With proper training, most technicians can become proficient in operating CNC stone cutting machines within a few weeks to a few months.

Q4: How does investing in a CNC stone cutting machine impact the overall cost of production?

A: While the initial investment in a CNC stone cutting machine can be significant, it often leads to reduced overall production costs in the long run. This is achieved through:

- Increased productivity and output

- Reduced labor costs

- Minimized material waste

- Fewer errors and less rework

- Ability to take on more complex, higher-value projects

The exact impact on production costs will vary depending on factors such as the volume of work, types of projects, and how effectively the machine is utilized. However, many stone fabrication shops report significant cost savings and increased profitability after integrating CNC technology into their operations.

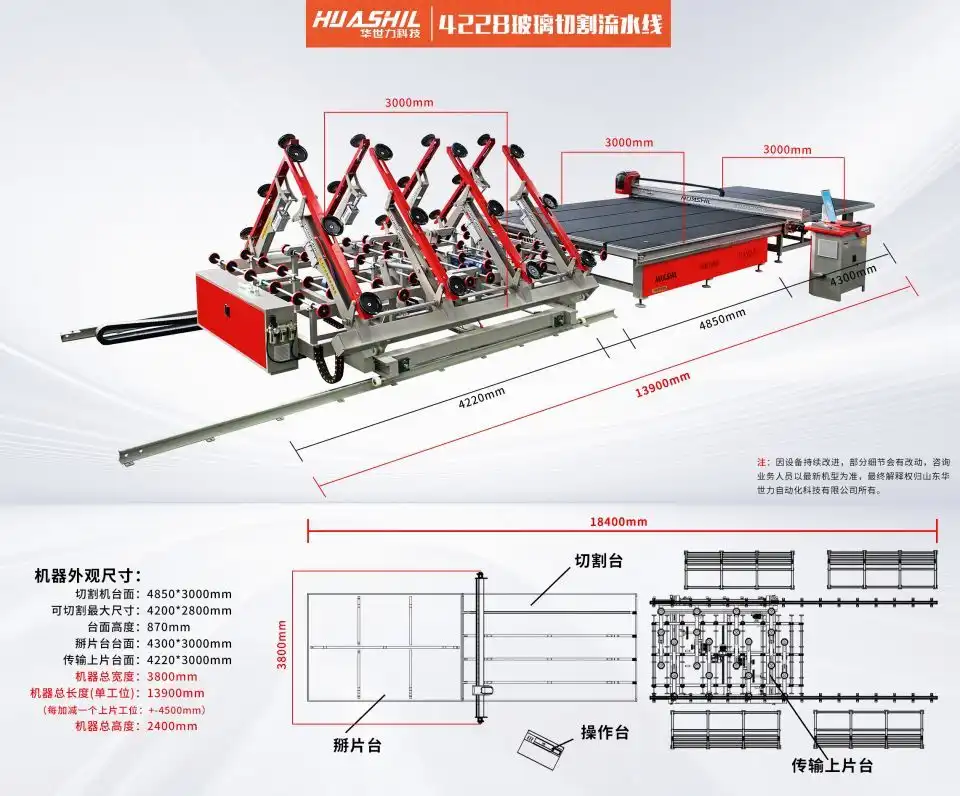

Choosing the Right CNC Stone Cutting Machine for Your Shop | HUASHIL

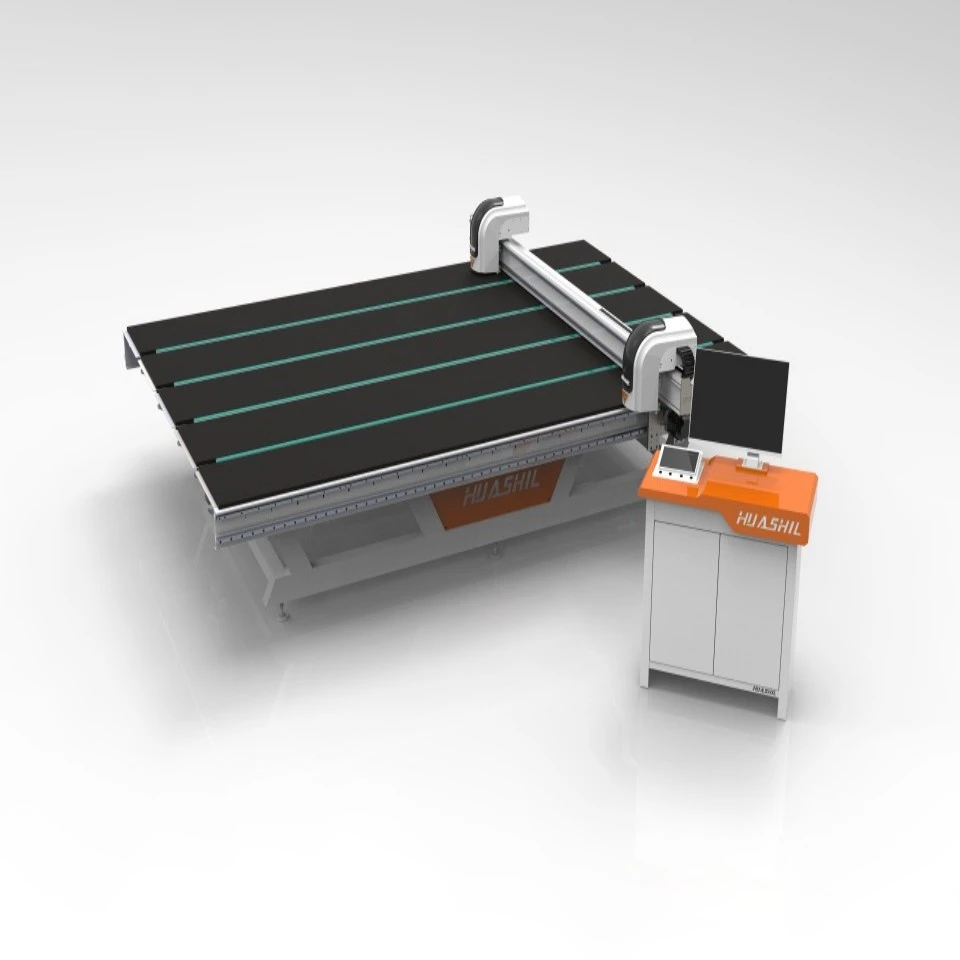

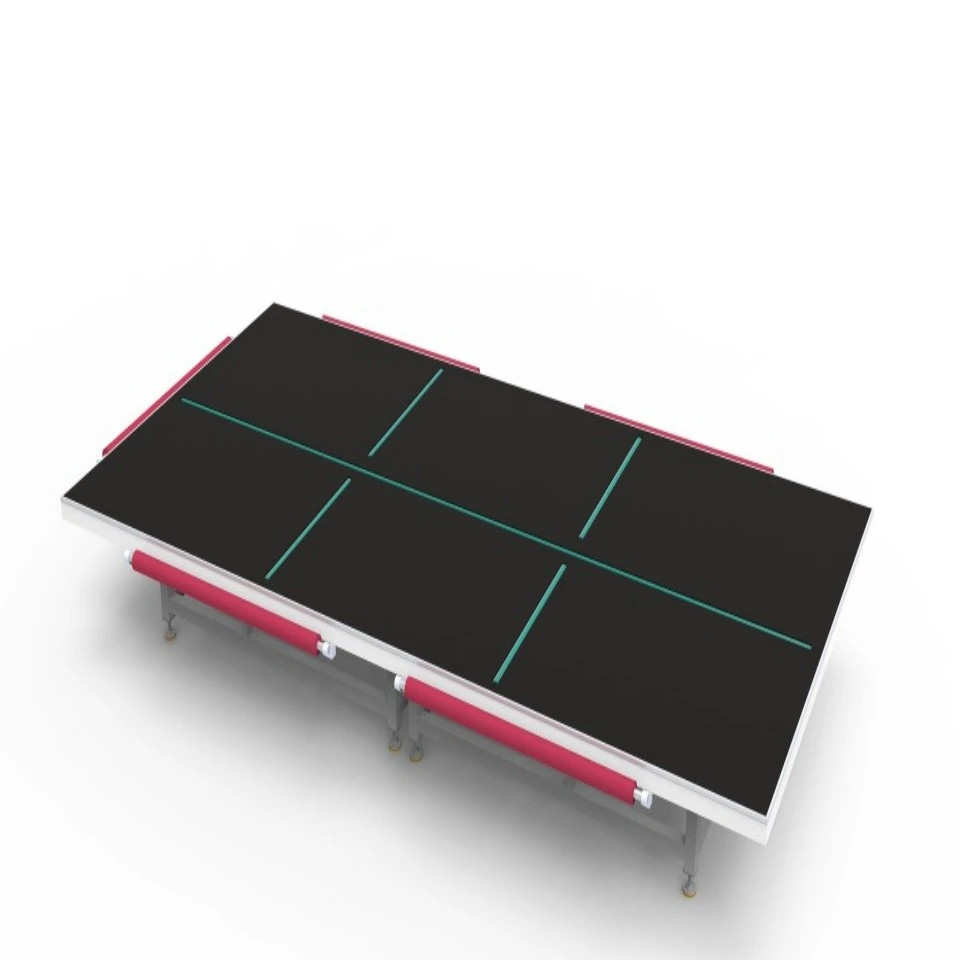

Selecting the ideal CNC stone cutting machine for your fabrication shop is a crucial decision that can significantly impact your business's efficiency and growth potential. At Shandong Huashil Automation Technology Co., LTD, we understand the unique needs of stone fabrication professionals and offer a range of high-quality CNC stone cutting solutions to meet those needs.

Our machines are designed with precision, durability, and user-friendliness in mind, ensuring that you can maximize your productivity while maintaining the highest quality standards. Whether you're looking to upgrade your existing equipment or investing in CNC technology for the first time, our team of experts is here to guide you through the selection process.

We offer customized solutions to fit your specific requirements, from compact machines for smaller shops to large-scale industrial solutions for high-volume production. Our commitment to innovation and customer satisfaction means you'll receive not just a machine, but a comprehensive solution that includes training, support, and ongoing service.

Ready to take your stone fabrication business to the next level? Contact us today at salescathy@sdhuashil.com to discuss your CNC stone cutting machine needs. Let Shandong Huashil Automation Technology Co., LTD be your partner in achieving precision, efficiency, and growth in your stone fabrication business.

References

1. Johnson, A. (2022). "The Evolution of CNC Technology in Stone Fabrication". Stone World Magazine, 39(4), 28-35.

2. Smith, R. & Brown, T. (2023). "Productivity Gains in Stone Fabrication: A Case Study of CNC Integration". Journal of Industrial Automation, 15(2), 112-126.

3. Garcia, M. et al. (2021). "Comparative Analysis of Manual vs. CNC Stone Cutting Techniques". International Journal of Materials Processing Technology, 56(3), 345-360.

4. Thompson, L. (2023). "The Economic Impact of CNC Adoption in Small to Medium Stone Fabrication Shops". Stone Industry Economic Report, 8(1), 15-29.