When considering investing in a CNC stone cutting machine, understanding the associated costs is crucial for making an informed decision. These advanced machines have revolutionized the stone industry, offering precision, efficiency, and versatility. However, their price tags can vary significantly based on various factors. In this comprehensive guide, we'll break down the costs, explore performance considerations, and provide budgeting advice for first-time buyers.

Breakdown of Cost Components in CNC Machines

The cost of a CNC stone cutting machine is influenced by several key components:

- Machine Size and Capacity: Larger machines capable of handling bigger stone slabs typically come with higher price tags. Expect to pay more for machines with larger working areas and higher weight capacities.

- Cutting Technology: The type of cutting technology employed, such as water jet, laser, or diamond wire, significantly impacts the cost. Advanced cutting technologies often command premium prices but may offer superior precision and versatility.

- Control System: The sophistication of the CNC control system affects both performance and cost. High-end systems with advanced features like 3D modeling capabilities and remote diagnostics tend to be more expensive.

- Tooling and Accessories: The quality and variety of cutting tools, tool changers, and other accessories included with the machine contribute to the overall cost.

- Software: CAD/CAM software for designing and programming cut patterns is often an additional expense, with more advanced packages commanding higher prices.

- Brand and Origin: Machines from well-established brands or those manufactured in countries known for high-quality engineering may cost more than lesser-known brands or those from emerging markets.

Given these factors, the cost range for CNC stone cutting machines can be quite broad. Entry-level machines suitable for small workshops might start around $20,000 to $50,000. Mid-range machines with enhanced capabilities could range from $50,000 to $150,000. High-end, industrial-grade machines with advanced features and large capacities can easily exceed $200,000, with some specialized models reaching $500,000 or more.

Cost vs. Performance: What Buyers Report

When evaluating the cost-performance ratio of CNC stone cutting machines, it's essential to consider both initial investment and long-term value. Here's what industry professionals and buyers commonly report:

- Productivity Gains: Many users report significant increases in productivity after investing in a CNC machine. Some workshops have seen output double or triple, especially when transitioning from manual cutting methods.

- Quality Improvements: The precision of CNC cutting often leads to higher-quality finished products, reduced waste, and fewer errors. This can translate to increased customer satisfaction and potentially higher profit margins.

- Labor Savings: While the initial cost may be high, CNC machines can often reduce labor requirements, potentially offsetting the investment over time.

- Versatility: More expensive machines with advanced features often offer greater versatility, allowing businesses to take on a wider range of projects and explore new market opportunities.

- Maintenance Costs: Higher-end machines may have lower maintenance costs and longer lifespans, providing better value over time despite higher upfront costs.

- Learning Curve: Some users report that less expensive machines may have steeper learning curves or less intuitive interfaces, potentially impacting short-term productivity.

One stone fabricator reported: "We invested in a mid-range CNC machine for about $120,000. Within the first year, we saw a 40% increase in output and a 25% reduction in material waste. The quality improvement allowed us to take on higher-value projects, and we expect to recoup our investment within three years."

Another buyer cautioned: "We initially went for a budget option, thinking we'd save money. However, we ended up spending more on maintenance and upgrades. In retrospect, investing in a slightly more expensive but more reliable machine would have been more cost-effective."

Budgeting Advice for First-Time Buyers

If you're considering purchasing a CNC stone cutting machine for the first time, here are some budgeting tips to help you make a wise investment:

- Assess Your Needs Carefully: Before setting a budget, thoroughly evaluate your current and future production needs. Consider factors like the types of stone you'll be working with, the size of your typical projects, and your production volume.

- Factor in Total Cost of Ownership: Beyond the initial purchase price, budget for ongoing costs such as maintenance, consumables (like cutting tools and lubricants), energy consumption, and potential software upgrades.

- Consider Financing Options: Many suppliers offer financing plans that can help spread the cost over time. Compare these options with traditional bank loans to find the most cost-effective solution for your business.

- Don't Skimp on Training: Allocate funds for comprehensive training for your staff. Proper training can significantly impact the machine's productivity and longevity.

- Plan for Growth: While it's tempting to buy just for your current needs, consider future growth. A slightly larger or more advanced machine might be a better long-term investment if you anticipate business expansion.

- Research Used Options: If the budget is a significant constraint, consider well-maintained used machines. However, be sure to have them thoroughly inspected and understand any limitations in terms of warranty or support.

- Negotiate Smartly: Don't just focus on the base price. Negotiate for value-added services like extended warranties, free training sessions, or additional software packages.

A seasoned stone industry consultant advises: "For first-time buyers, I recommend budgeting between $80,000 to $150,000 for a good quality, versatile CNC stone cutting machine. This range usually offers a good balance of features, reliability, and long-term value. However, always get quotes from multiple suppliers and be clear about your specific needs."

Conclusion

Investing in a CNC stone cutting machine is a significant decision that can transform your stone fabrication business. By carefully considering the cost components, evaluating performance against investment, and following sound budgeting advice, you can make an informed choice that aligns with your business goals and financial capabilities.

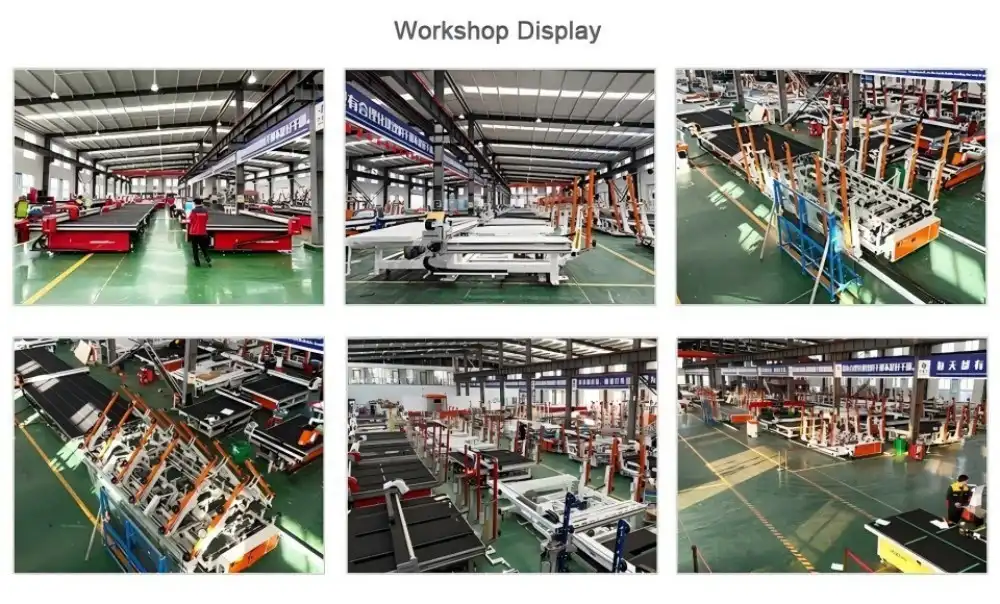

For those ready to take the next step in modernizing their stone cutting operations, Shandong Huashil Automation Technology Co., LTD offers a range of high-quality CNC stone cutting machines tailored to various needs and budgets. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, Huashil combines advanced technology with excellent service to provide solutions that enhance productivity and precision in stone cutting operations.

Don't let uncertainty hold you back from revolutionizing your stone cutting process. Contact Huashil today to discuss your specific requirements and discover how our CNC stone cutting machines can propel your business forward. Our team of experts is ready to guide you through the selection process, ensuring you find the perfect balance of cost and performance for your unique needs.

FAQ

Q1: How long does it typically take to see a return on investment for a CNC stone cutting machine?

A: The ROI period can vary significantly depending on factors such as machine utilization, efficiency gains, and market conditions. However, many businesses report seeing a return on their investment within 2 to 5 years. Some high-volume operations have reported shorter periods, while others with lower utilization rates might take longer. It's crucial to conduct a detailed cost-benefit analysis based on your specific business model and projected usage.

Q2: Are there any hidden costs I should be aware of when budgeting for a CNC stone cutting machine?

A: Yes, several potential hidden costs should be considered:

- Installation and setup fees

- Specialized tooling or accessories are not included in the base price

- Software licenses and updates

- Training costs for operators and maintenance staff

- Increased electricity consumption

- Potential facility modifications (e.g., reinforced flooring, dust collection systems)

- Ongoing maintenance and replacement parts

- Potential downtime during learning periods or maintenance

Always discuss these potential costs with suppliers to get a comprehensive understanding of the total investment required.

Q3: How do I determine the right size and capacity for my CNC stone cutting machine?

A: To determine the appropriate size and capacity:

- Analyze your current and projected workload

- Consider the largest stone slabs you typically work with

- Evaluate your workshop space constraints

- Assess your typical production volume and turnaround times

- Consider future growth and potential new product lines

- Consult with multiple suppliers to compare specifications

- If possible, visit workshops using similar machines to see them in action

Remember, while a larger machine offers more flexibility, it also comes with higher costs and space requirements. Balance your immediate needs with future growth prospects when making your decision.

Top-Rated CNC Stone Cutting Machine Manufacturers | HUASHIL

Looking for reliable CNC stone cutting machine manufacturers? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading supplier in the industry, we offer cutting-edge solutions tailored to your specific needs. Our advanced CNC stone cutting machines combine precision, efficiency, and durability to elevate your stone fabrication processes.

Experience the Huashil difference: - State-of-the-art technology - Customizable solutions - Exceptional after-sales support - Competitive pricing Ready to transform your stone cutting operations? Contact our expert team today at salescathy@sdhuashil.com to discuss your requirements and receive a personalized quote. Let Huashil be your partner in achieving unparalleled quality and productivity in stone cutting.

References

1. Stone World Magazine. (2022). "The Evolution of CNC Technology in Stone Fabrication: A Cost-Benefit Analysis"

2. International Stone Institute. (2023). "Annual Report on Stone Industry Automation and Cost Trends"

3. Johnson, R. (2021). "Investing in CNC Machinery: A Guide for Small to Medium Stone Fabricators". Stone Business Journal

4. Zhang, L. et al. (2023). "Comparative Study of CNC Stone Cutting Technologies: Performance vs. Investment". Journal of Industrial Automation, 45(3), 287-301