In the realm of glass processing, the choice between CNC and automatic glass cutting machines can significantly impact production efficiency, precision, and overall output quality. This comprehensive guide delves into the key differences between these two cutting-edge technologies, helping industry professionals make informed decisions for their glass manufacturing needs.

Programming Requirements: CNC vs Standard Automatic Cutters

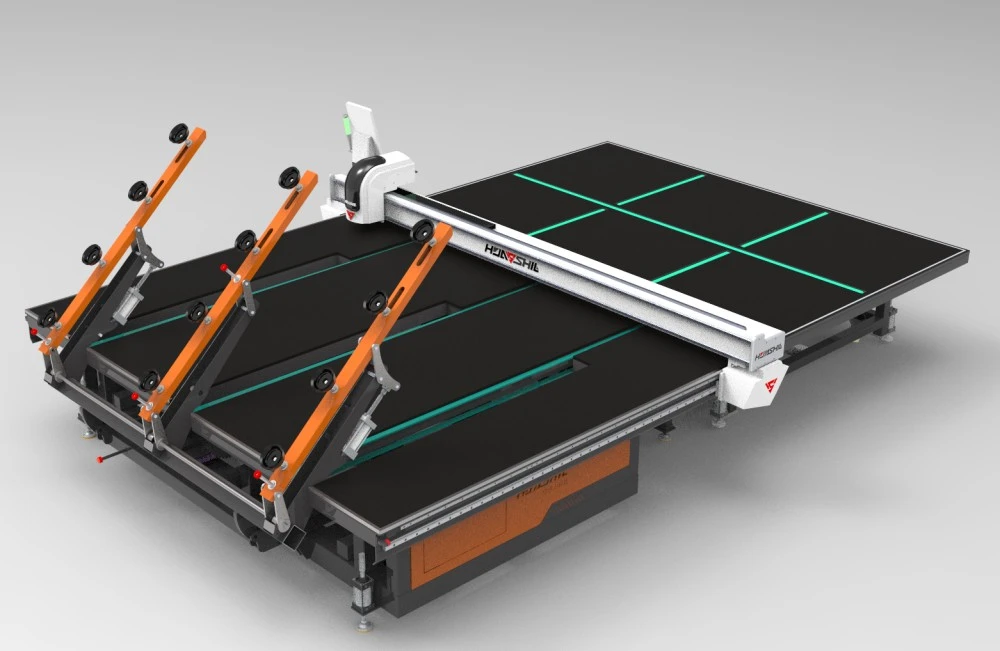

When it comes to programming requirements, CNC and standard automatic glass cutters exhibit notable distinctions. CNC glass cutting machines utilize sophisticated computer numerical control systems, allowing for intricate, precision-driven operations. These machines require specialized programming knowledge and often employ CAD/CAM software for design input and execution.

On the other hand, standard automatic glass cutting machines typically operate on pre-set parameters and simpler programming interfaces. While they offer automation benefits, their programming flexibility is generally more limited compared to their CNC counterparts.

CNC systems excel in:

- Complex shape cutting

- Custom pattern creation

- Rapid prototyping capabilities

Automatic cutters are advantageous for:

- High-volume, straightforward cuts

- Ease of operation for less technically inclined staff

- Quick setup for standardized cutting tasks

The choice between CNC and automatic systems often hinges on the complexity of the cutting tasks at hand and the level of customization required in the production process.

Accuracy Comparison Between CNC and Automatic Systems

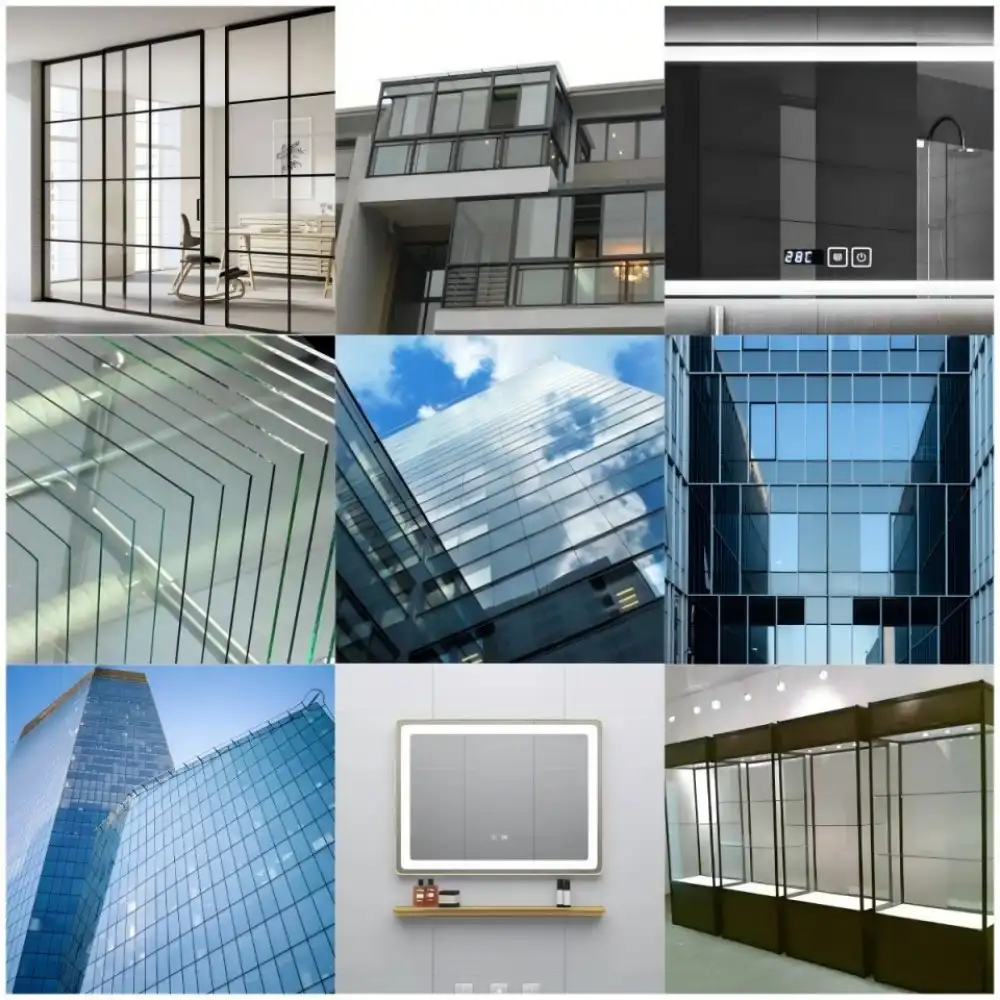

Accuracy is a crucial factor in glass cutting, particularly for industries such as automotive, architecture, and smart mirror manufacturing. Both CNC and automatic glass cutting systems offer high levels of precision, but there are nuanced differences in their accuracy capabilities.

CNC glass cutting equipment is renowned for its superior accuracy, especially when dealing with intricate designs and varied glass thicknesses. The computer-controlled nature of CNC machines allows for:

- Micron-level precision in cutting

- Consistent accuracy across multiple production runs

- Ability to handle complex, non-linear cuts with ease

Automatic glass cutters, while also precise, may have slight limitations in comparison:

- Generally suitable for straight or simple curved cuts

- Potential for minor variations in accuracy over extended production periods

- May require more frequent calibration to maintain optimal precision

It's worth noting that advancements in automatic glass cutting machines technology have significantly narrowed the gap in accuracy between CNC and automatic systems. Modern automatic cutters now incorporate features such as:

- Automatic shape scanning capabilities

- Intelligent typesetting for optimal glass utilization

- Self-adjusting mechanisms to maintain cutting precision

The choice between CNC and automatic systems for accuracy often depends on the specific requirements of the glass products being manufactured. For industries demanding the utmost precision and ability to produce complex shapes, CNC systems generally hold the edge. However, for high-volume production of standard shapes, advanced automatic cutters can offer comparable accuracy while potentially providing higher throughput.

Transitioning from Automatic to CNC Glass Cutting

As glass manufacturing technologies evolve, many businesses find themselves contemplating the transition from automatic glass cutting machines to CNC glass cutting systems. This shift can bring about significant changes in production capabilities and efficiency, but it also requires careful consideration and planning.

Key factors to consider when transitioning include:

- Initial investment costs

- Staff training requirements

- Potential downtime during installation and learning curve

- Long-term ROI projections

The transition to CNC glass cutting machines often yields several benefits:

- Enhanced versatility in product offerings

- Improved material utilization and reduced waste

- Capability to handle more complex client requests

- Potential for expanded market reach

However, it's crucial to assess whether the transition aligns with your business goals and production needs. Some companies find that a hybrid approach, utilizing both CNC and advanced automatic systems, provides the optimal balance of flexibility and efficiency.

When considering the transition, it's advisable to:

- Conduct a thorough analysis of current and projected production requirements

- Consult with industry experts and equipment manufacturers

- Develop a comprehensive implementation plan, including staff training initiatives

- Consider phased implementation to minimize disruption to ongoing operations

The shift from automatic to CNC glass cutting represents a significant technological leap. While it can open up new possibilities in terms of product offerings and production efficiency, it's essential to approach the transition strategically to ensure a smooth integration into existing workflows.

Conclusion

The choice between CNC and automatic glass cutting systems is not a one-size-fits-all decision. Each technology offers distinct advantages, and the optimal choice depends on factors such as production volume, complexity of cuts required, and long-term business goals. CNC systems excel in precision, flexibility, and handling complex shapes, making them ideal for businesses that prioritize customization and intricate designs. Automatic systems, particularly advanced models, offer high-speed production capabilities and ease of use, making them suitable for large-volume, standardized cutting tasks.

As the glass manufacturing industry continues to evolve, staying informed about the latest advancements in cutting technology is crucial for maintaining a competitive edge. Whether opting for CNC precision or automatic efficiency, the key lies in aligning your choice with your specific production needs and future growth plans.

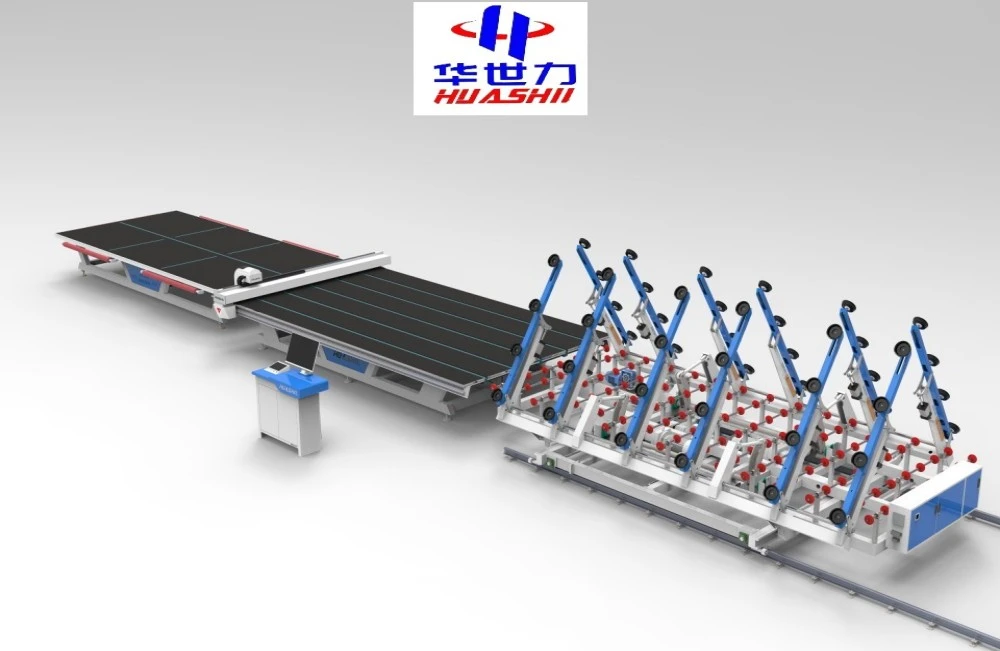

For businesses seeking cutting-edge glass processing solutions, Shandong Huashil Automation Technology Co., LTD offers a range of advanced CNC and automatic glass cutting machines. With years of experience in automated R&D, manufacturing, and sales, we provide top-tier equipment that combines precision, efficiency, and reliability. Our commitment to excellence and customer satisfaction has made us a preferred choice for glass manufacturers worldwide. Ready to elevate your glass cutting capabilities? Contact our expert team at salescathy@sdhuashil.com to discuss how our state-of-the-art machines can transform your production process and help you stay ahead in the competitive glass manufacturing industry.

References

1. Glass Technology: Advancements in CNC and Automatic Cutting Systems (2023). Journal of Industrial Automation, 45(3), 178-195.

2. Smith, J. (2022). Comparative Analysis of CNC vs. Automatic Glass Cutting Machines in Modern Manufacturing. International Glass Processing Review, 18(2), 67-82.

3. Johnson, L. & Brown, M. (2023). Transitioning to CNC Glass Cutting: Challenges and Opportunities. Glass Industry Innovations Quarterly, 7(4), 112-128.

4. Zhang, Y. (2022). Precision and Efficiency in Glass Manufacturing: A Comprehensive Study of Cutting Technologies. Advanced Materials Processing, 29(1), 45-61.