Selecting the right CNC glass machine speaks to one of the most basic choices for any glass preparation operation. With present-day robotization changing the glass production industry, finding the culminate CNC glass cutting gear can significantly boost your generation productivity, while guaranteeing accuracy that manual forms basically cannot coordinate. This comprehensive direct strolls you through everything you require to know about choosing the ideal glass cutting and handling apparatus for your particular industry needs. From understanding key choice criteria to analyzing territorial showcase inclinations, we'll offer assistance you make an educated speculation that drives your trade forward.

Why CNC Glass Machines Are Essential for Modern Manufacturing?

The glass handling industry has experienced an exceptional change in later a long years. Conventional manual cutting strategies, although still profitable for certain applications, cannot compete with the speed, exactness, and consistency that CNC innovation conveys. Cutting-edge glass manufacturing requires accurate machining capabilities that meet progressively exacting quality guidelines across businesses extending from car to building applications. CNC glass cutting hardware utilizes computer numerical control frameworks to execute complex cutting designs with repeatability that manual operations cannot accomplish. These robotized frameworks coordinated consistently with CAD/CAM programs, permitting administrators to decipher computerized plans specifically into physical items. The result is drastically decreased squander, progressed product quality, and overall speedier production cycles. Businesses contributing to CNC processing and cutting innovation ordinarily see a return on investment within 12-18 months through decreased labor costs and increased throughput. The accuracy these machines offer becomes especially important when working with costly materials like tempered glass or specialized building glass panels.

Key Selection Criteria for CNC Glass Processing Equipment

Choosing the ideal CNC glass machine requires cautious assessment of a few basic variables. Generation capacity stands as the essential thought - your gear must handle your current volume, whereas giving room for development. Preparing speed, measured in direct meters per diminutive, specifically impacts your operational proficiency and profitability. Technical details matter massively in glass innovation applications. Cutting exactness, regularly measured in hundredths of millimeters, decides whether your items meet industry benchmarks. Edge cleaning capabilities and boring machine integration grow your preparation choices, permitting you to offer comprehensive services to customers. Software compatibility speaks to another significant figure. Present-day CAD/CAM computer program integration empowers consistent workflow from plan to generation. See frameworks that back different record groups and offer natural programming interfaces that diminish administrator preparation time. Maintenance necessities and parts accessibility essentially affect the amount of time to take over proprietorship. Solid providers give comprehensive specialized back, guaranteeing negligible downtime and steady production plans. Consider sellers who offer nearby benefit systems in your region.

Top 5 CNC Glass Machines for Different Industry Applications

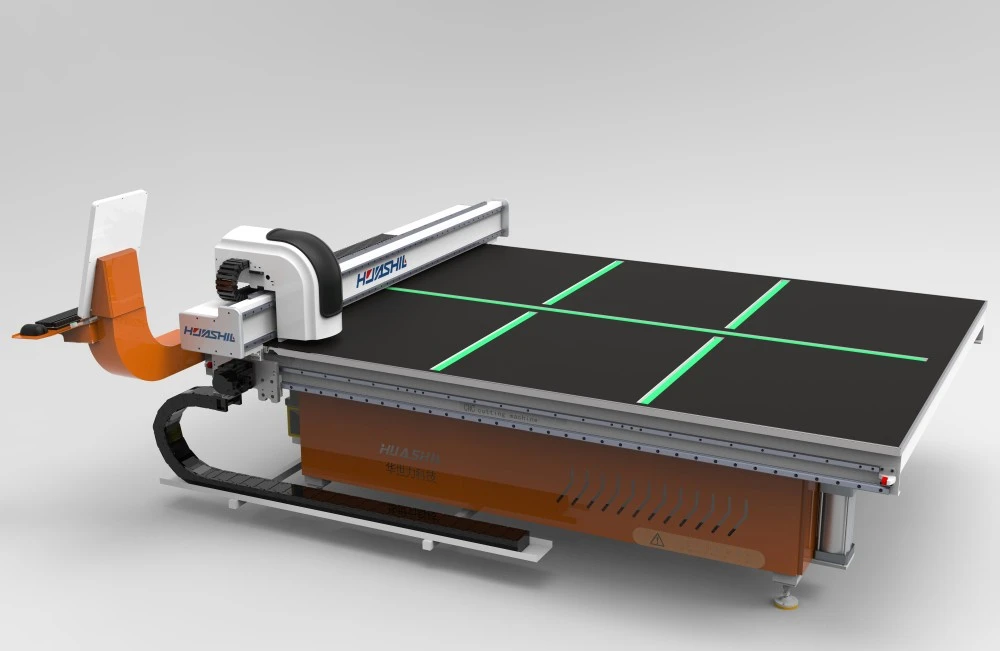

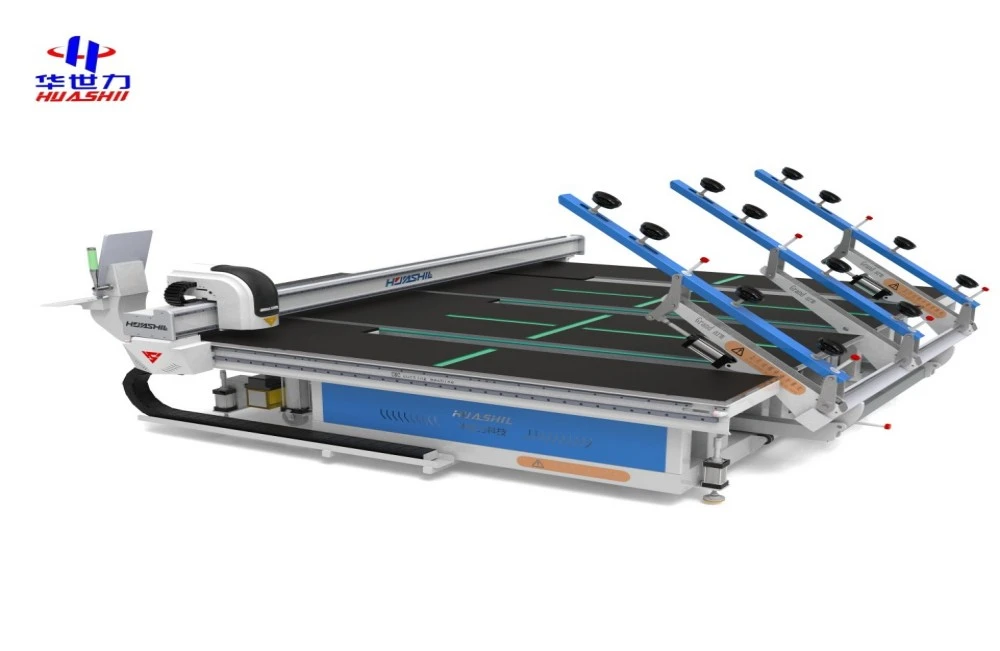

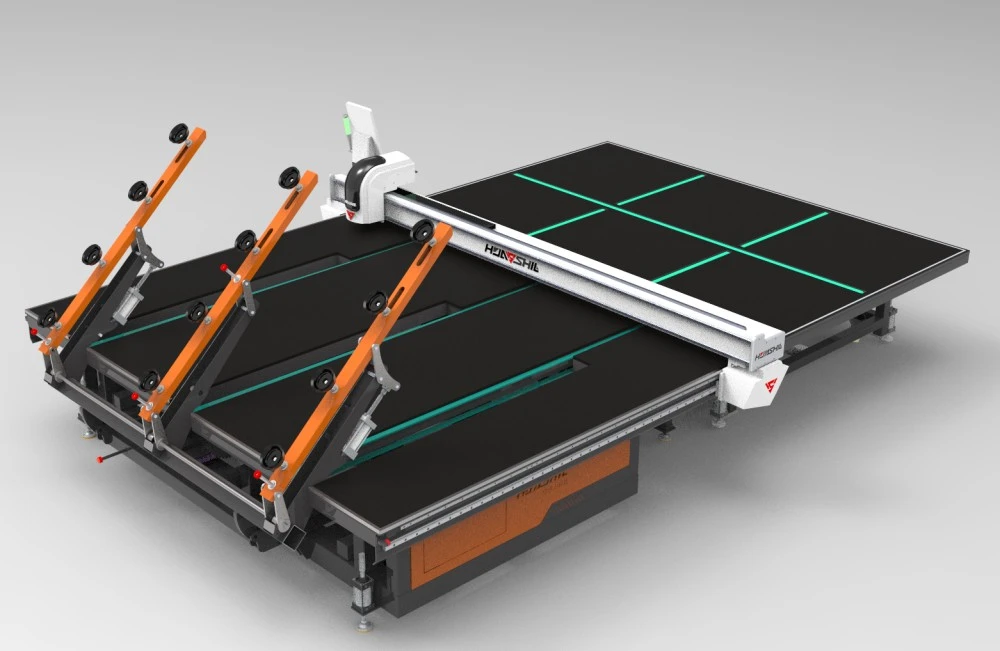

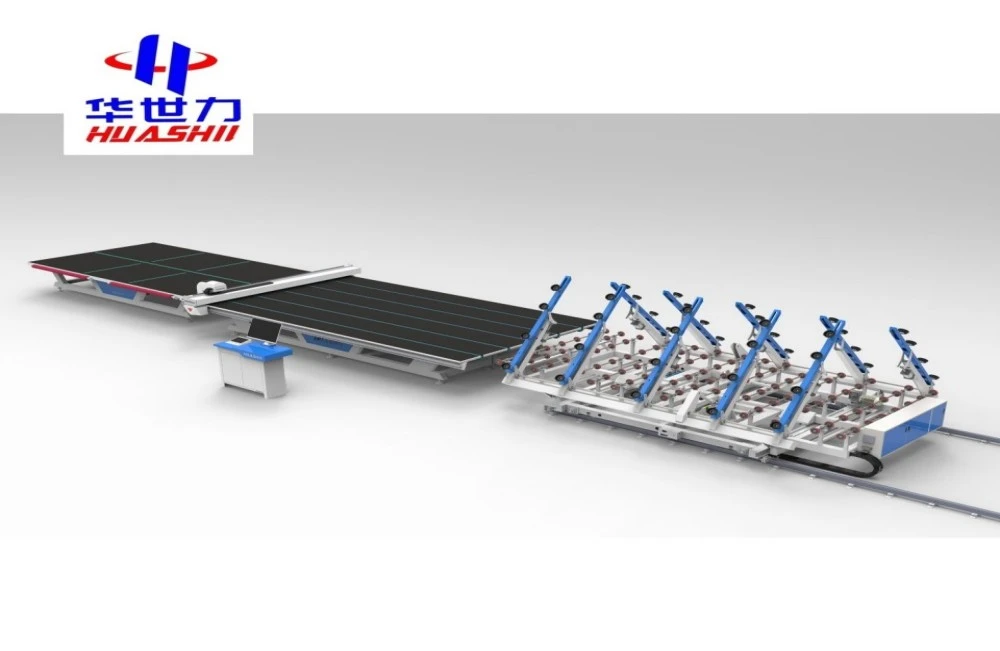

High-Speed Flat Glass Cutting System

This advanced CNC glass cutting machine excels in high-volume architectural glass processing applications. The system features multi-head cutting capabilities that can simultaneously process multiple glass sheets, dramatically increasing throughput for large-scale projects.

Key advantages include:

- Processing speeds up to 120 meters per minute for standard flat glass

- Automatic glass loading and unloading systems that reduce labor requirements

- Precision cutting accuracy within ±0.1mm tolerance levels

- Integrated edge polishing stations that eliminate secondary processing

- Advanced safety systems, including automatic glass breakage detection

- Comprehensive waste management systems that optimize material utilization

- Compatible with glass thicknesses ranging from 3mm to 25mm

- Energy-efficient servo motor systems that reduce operational costs

This equipment particularly suits large architectural glass manufacturers and curtain wall fabricators who require consistent quality across high-volume production runs. The automated loading systems make it ideal for processing standard glass sizes used in commercial construction projects.

Precision Glass Drilling and Milling Center

Specialized for complex glass shaping operations, this machining center combines drilling, milling, and edge processing capabilities in a single platform. The system excels in producing intricate glass components for electronics, automotive, and decorative applications.

Notable features include:

- Multi-axis CNC control enabling complex 3D glass processing

- High-speed spindles operating up to 60,000 RPM for precise drilling operations

- Automatic tool changing systems with capacity for 20+ different cutting tools

- Integrated cooling systems that prevent thermal stress during processing

- Advanced vibration dampening that ensures smooth surface finishes

- Precise positioning accuracy within ±0.05mm for critical dimensions

- Capability to process both flat glass and curved glass surfaces

- Specialized software for optimizing cutting paths and reducing cycle times

This equipment serves manufacturers producing specialized glass components, including electronics housings, automotive glass panels, and custom architectural elements requiring precise hole patterns or complex edge profiles.

Automated Glass Engraving and Beveling System

Designed for decorative glass processing, this CNC system specializes in creating intricate patterns, beveled edges, and artistic glass elements. The machine combines traditional glass craftsmanship techniques with modern automation technology.

System capabilities include:

- Variable-depth engraving from 0.1mm to 5mm for artistic applications

- Automatic beveling with adjustable angles from 5° to 45°

- Laser cutting integration for extremely precise pattern work

- Multi-stage polishing systems that achieve mirror-finish quality

- Programmable pattern libraries with thousands of pre-designed templates

- Custom pattern creation through advanced CAD integration

- Automatic glass positioning systems that handle irregular shapes

- Dust collection systems that maintain clean working environments

This equipment targets furniture manufacturers, interior designers, and specialized glass artists who require sophisticated decorative processing capabilities while maintaining production efficiency.

Waterjet Glass Cutting System

Utilizing high-pressure water streams with abrasive materials, this system cuts through virtually any glass type without introducing thermal stress. The technology proves particularly valuable for processing thick glass sections and complex geometries.

Advantages include:

- Capability to cut glass thicknesses up to 150mm without edge chipping

- Cold cutting process that eliminates thermal stress and cracking

- Complex curve cutting with radius capabilities down to 2mm

- No tool wear concerns, reducing long-term operational costs

- Minimal material waste through optimized nesting software

- Ability to cut laminated and safety glass without delamination

- Precise edge quality that often eliminates secondary finishing

- Environmental safety through closed-loop water recycling systems

This technology serves specialized applications, including thick architectural glass, safety glass processing, and complex artistic installations where traditional cutting methods prove inadequate.

Compact Glass Processing Workstation

Engineered for smaller operations and specialized applications, this compact system provides comprehensive glass processing capabilities within a minimal footprint. The design emphasizes versatility and ease of operation for smaller production runs.

Key benefits include:

- Space-efficient design requiring less than 20 square meters of floor space

- Modular configuration allowing customization based on specific needs

- User-friendly interface reduces operator training requirements

- Quick changeover capabilities for processing different glass types

- Integrated quality control systems with automatic measurement

- Cost-effective entry point for businesses expanding into automation

- Flexible tooling options supporting various processing operations

- Remote monitoring capabilities for production tracking

This equipment suits smaller glass fabricators, prototype development facilities, and businesses requiring flexible processing capabilities without the investment of larger industrial systems.

Regional Market Analysis and Considerations

Understanding regional market characteristics proves essential when selecting CNC glass processing equipment. Each geographic region presents unique opportunities, challenges, and regulatory requirements that influence equipment selection and operational strategies.

Southeast Asian markets demonstrate strong growth in architectural glass demand, driven by rapid urbanization and infrastructure development. Countries like Vietnam, Thailand, and Indonesia show particular interest in energy-efficient building materials, creating opportunities for advanced glass processing technologies. Local regulations increasingly emphasize environmental compliance, making energy-efficient CNC systems particularly attractive.

Russian markets traditionally focus on heavy-duty equipment capable of handling extreme operating conditions. The preference leans toward robust, reliable systems with minimal maintenance requirements. Glass fabrication in this region often involves larger format processing for industrial applications, requiring equipment with substantial processing capabilities.

South American markets show growing demand for decorative and architectural glass applications. Brazil and Argentina lead regional growth, with increasing emphasis on modern building designs incorporating extensive glass elements. Equipment selection often prioritizes versatility and the ability to handle diverse project requirements.

Middle Eastern markets demonstrate strong demand for luxury and high-end glass applications. The region's focus on prestigious architectural projects creates opportunities for advanced glass processing technologies. Equipment must handle extreme environmental conditions while maintaining precision and reliability.

Purchasing Recommendations and Strategic Considerations

Successful CNC glass machine acquisition requires careful planning and strategic thinking beyond initial equipment costs. Total cost of ownership analysis should encompass installation, training, maintenance, and operational expenses over the equipment's expected lifespan.

Vendor selection proves equally important as equipment selection. Choose suppliers with proven track records in your specific industry and geographic region. Evaluate their technical support capabilities, spare parts availability, and training programs. Local service networks can significantly reduce downtime and operational disruptions.

Consider equipment scalability and future expansion possibilities. Modular systems allow gradual capacity increases as business grows, while integrated automation options can enhance efficiency over time. Software upgrade paths ensure your equipment remains current with evolving industry standards.

Financing options vary significantly across regions and vendors. Explore leasing arrangements, equipment loans, and supplier financing programs. Many manufacturers offer attractive terms for international buyers, including deferred payment schedules aligned with project completion milestones.

Industry Trends and Future Outlook

The glass processing industry continues evolving toward greater automation and integration. Smart factory concepts incorporating IoT connectivity and predictive maintenance systems are becoming increasingly common. Artificial intelligence integration helps optimize cutting patterns and reduce material waste. Sustainability concerns drive the development of energy-efficient processing technologies and recycling capabilities. These trends suggest that investing in advanced, connected CNC glass machines positions businesses for future success in an increasingly competitive marketplace.

Conclusion

Selecting the right CNC glass machine requires cautious assessment of your particular generation needs, showcase necessities, and long-term commerce goals. The speculation in quality computerization hardware pays profits through progressed productivity, reliable quality, and decreased operational costs. By considering the variables laid out in this direct and joining forces with experienced providers like HUASHIL, you can make certain choices that drive your glass handling operation toward supported victory and development in a progressively automated industry.

Frequently Asked Questions

1. What thickness range can CNC glass machines typically handle?

Most CNC glass cutting machines handle glass thicknesses from 2mm to 25mm effectively. Specialized waterjet systems can process glass up to 150mm thick, while standard cutting systems work best with common architectural glass thicknesses between 4mm and 12mm.

2. How long does operator training typically take for CNC glass equipment?

Basic operation training usually requires 2-3 weeks for experienced glass workers. Advanced programming and maintenance training may take 1-2 months. Modern systems with intuitive interfaces significantly reduce learning curves compared to older equipment.

3. What maintenance requirements should I expect for CNC glass machines?

Regular maintenance includes daily cleaning, weekly lubrication, and monthly calibration checks. Professional service visits typically occur quarterly or biannually, depending on usage intensity. Preventive maintenance significantly extends equipment life and maintains cutting accuracy.

Partner with HUASHIL for Your CNC Glass Machine Needs

Shandong Huashil Automation Technology has established itself as a leading CNC glass machine manufacturer, serving glass fabricators worldwide with advanced automation solutions. Our comprehensive product line includes cutting-edge glass processing equipment designed to meet diverse industry requirements across architectural, automotive, and decorative applications.

HUASHIL's engineering team brings decades of experience in glass technology and numerical control systems. We understand the unique challenges facing glass processors in today's competitive market and develop solutions that address real-world production needs. Our equipment undergoes rigorous testing to ensure reliability and precision that customers depend on.

We offer complete support throughout the equipment lifecycle, from initial consultation through installation, training, and ongoing technical assistance. Our global service network ensures rapid response times and comprehensive spare parts availability. Whether you need a single machine or complete production line integration, HUASHIL provides customized solutions that fit your specific requirements and budget.

Ready to transform your glass processing capabilities? Our experienced sales team can help you select the optimal CNC glass machine for sale that matches your production goals and operational requirements. Contact us at salescathy@sdhuashil.com to discuss your project and receive a detailed proposal tailored to your specific needs.