Key Factors in Choosing Custom Glass Cutting Solutions

When considering a customized glass cutting table, several crucial factors come into play. These elements will significantly impact the efficiency and effectiveness of your glass cutting operations:

Production Volume and Capacity

One of the primary considerations when customizing your glass cutting equipment is the volume of production you anticipate. A bespoke solution should be capable of handling your current output while also accommodating potential growth. This may involve features such as:

- Multiple cutting heads for simultaneous operations

- Automated loading and unloading systems

- Enhanced software for optimized cutting patterns

By tailoring your machine to your specific production needs, you can ensure maximum efficiency and minimize downtime.

Glass Types and Thicknesses

Different glass types and thicknesses require varying cutting techniques and tools. A customized glass cutting table machine can be engineered to handle a wide range of glass products, including:

- Float glass

- Laminated glass

- Low-E glass

- Tempered glass

By specifying the exact types of glass you work with, your custom solution can be outfitted with the appropriate cutting wheels, scoring tools, and pressure systems to ensure clean, precise cuts across all your products.

Cutting Patterns and Shapes

While standard glass cutting tables excel at straight cuts, many industries require more complex shapes and patterns. A customized machine can be designed to handle intricate cutting requirements, such as:

- Curved and circular cuts

- Irregular shapes for architectural glass

- Precise holes and notches

Advanced software integration can allow for seamless importing of CAD designs, ensuring accuracy and reducing waste in complex cutting operations.

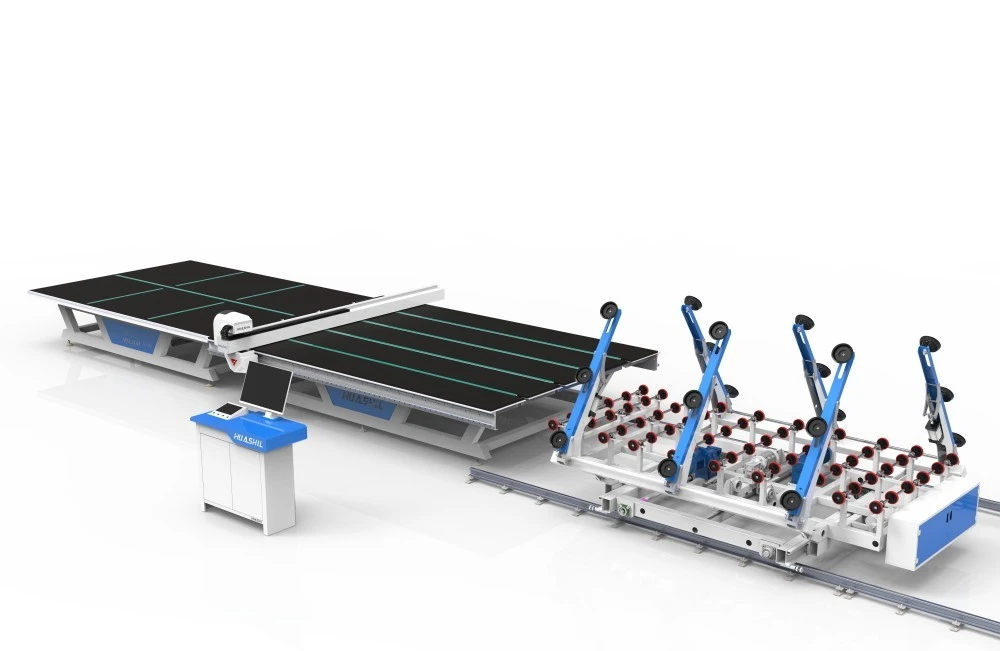

Automation and Integration

In today's fast-paced manufacturing environment, automation is crucial for maintaining competitiveness. When customizing your glass cutting equipment, consider how it will integrate with your existing production line. Options may include:

- Robotic arms for glass handling

- Integration with ERP systems for real-time production tracking

- Automated quality control systems

By streamlining your processes through automation, you can significantly reduce labor costs and minimize human error.

Safety Features

Safety should always be a top priority when working with glass. Custom glass cutting equipment can incorporate advanced safety features tailored to your specific working environment, such as:

- Enhanced emergency stop systems

- Protective enclosures with interlocking doors

- Advanced sensors to detect operator presence

These safety measures not only protect your workers but also help ensure compliance with industry regulations.

ROI of Tailored Glass Cutting Machines

Investing in a customized glass cutting table machine represents a significant upfront cost. However, the long-term return on investment (ROI) can be substantial when considering the following factors:

Increased Productivity

A bespoke glass cutting solution optimized for your specific needs can dramatically increase your production output. This boost in productivity can be attributed to:

- Reduced setup times between different glass types or thicknesses

- Faster cutting speeds due to optimized tooling

- Minimized downtime for maintenance or adjustments

By streamlining your operations, you can take on more projects and increase your revenue potential.

Improved Quality and Precision

Custom glass cutting table machines can be engineered to meet exacting quality standards. This precision results in:

- Reduced waste from miscuts or breakage

- Fewer rejections from customers

- Enhanced reputation for high-quality products

The ability to consistently produce top-quality glass products can lead to increased customer satisfaction and repeat business.

Energy Efficiency

Modern, customized glass cutting equipment often incorporates energy-saving features such as:

- Efficient motors and drives

- Optimized cutting paths to reduce machine movement

- Smart power management systems

These energy-efficient designs can lead to significant cost savings over the life of the machine.

Flexibility for Future Growth

A well-designed custom glass cutting solution should be adaptable to future needs. This flexibility can provide:

- Scalability to handle increased production volumes

- Ability to accommodate new glass types or cutting requirements

- Easier integration of future technological advancements

By investing in a flexible, customized solution, you can future-proof your operations and avoid the need for frequent equipment replacements.

Reduced Labor Costs

Automation and customization can significantly reduce the need for manual labor in your glass cutting operations. This reduction in labor costs can be achieved through:

- Automated loading and unloading systems

- Simplified operation requiring fewer skilled operators

- Reduced need for manual quality checks

By optimizing your workforce, you can allocate resources more efficiently and improve your overall profitability.

Case Study: Successful Custom Machine Implementation

To illustrate the tangible benefits of customizing a glass cutting table machine, let's examine a real-world case study:

Company Background

XYZ Glass Solutions, a mid-sized manufacturer specializing in architectural glass, faced challenges meeting increasing demand for complex, custom-shaped glass panels. Their existing equipment was limited to standard rectangular cuts, requiring extensive manual work for intricate shapes.

The Challenge

XYZ Glass Solutions needed a solution that could:

- Handle a wide range of glass thicknesses (3mm to 19mm)

- Cut complex shapes with high precision

- Integrate with their existing CAD software

- Increase production capacity by at least 50%

The Custom Solution

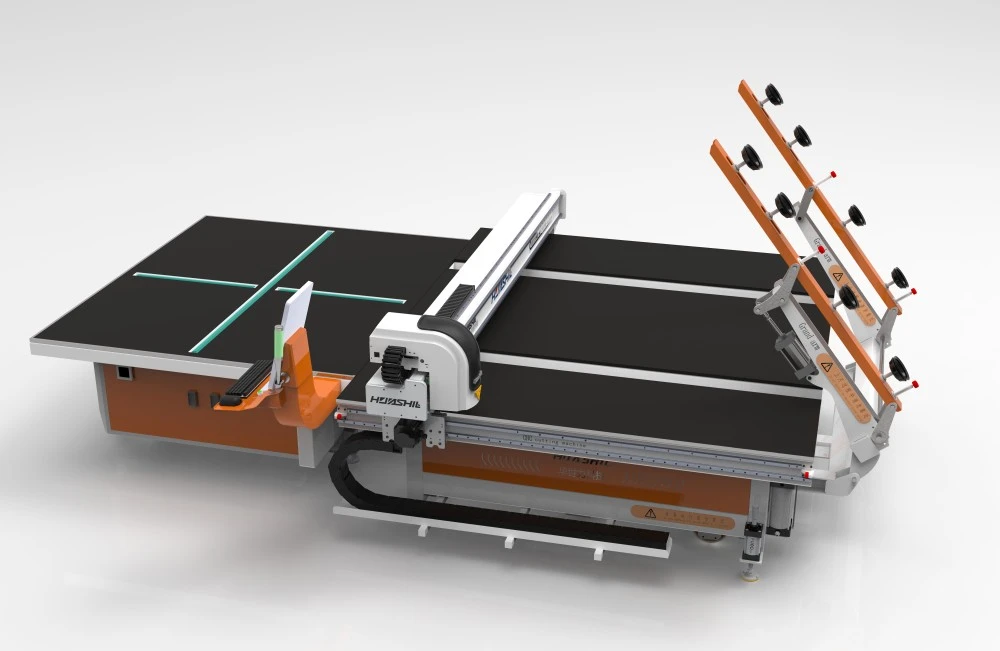

Working closely with a reputable glass cutting equipment manufacturer, XYZ Glass Solutions developed a customized glass cutting table machine that featured:

- A multi-head cutting system for simultaneous operations

- Advanced CNC controls for intricate shape cutting

- Automated loading and unloading systems

- Integrated software for seamless CAD file import

- Adjustable pressure controls for various glass thicknesses

The Results

After implementing the custom glass cutting solution, XYZ Glass Solutions experienced:

- A 75% increase in production capacity

- Reduction in waste material by 30%

- Ability to take on complex projects previously outsourced

- Improved customer satisfaction due to faster turnaround times

- 20% reduction in labor costs

The initial investment in the customized equipment was recouped within 18 months, and XYZ Glass Solutions saw a significant boost in profitability and market share.

Lessons Learned

This case study highlights several key takeaways for companies considering custom glass cutting solutions:

- Thorough analysis of current and future needs is crucial

- Close collaboration with equipment manufacturers ensures optimal results

- Integration with existing systems and workflows is essential for success

- The initial investment can lead to substantial long-term benefits

By carefully considering these factors, other glass manufacturers can replicate the success of XYZ Glass Solutions and gain a competitive edge in the market.

Conclusion

Customizing your glass cutting table machine is a strategic decision that can propel your business to new heights of efficiency and profitability. By carefully considering your specific needs, from production volume to cutting patterns, you can create a tailored solution that not only meets your current requirements but also positions you for future growth.

The return on investment for a custom glass cutting solution extends beyond mere financial gains. Improved quality, increased flexibility, and enhanced safety all contribute to a stronger, more competitive business. As demonstrated by the case study, the benefits of customization can be transformative, allowing companies to take on new challenges and expand their market presence.

As you contemplate the future of your glass processing operations, consider the power of customization. A bespoke glass cutting table machine could be the key to unlocking your company's full potential in the dynamic world of glass manufacturing.

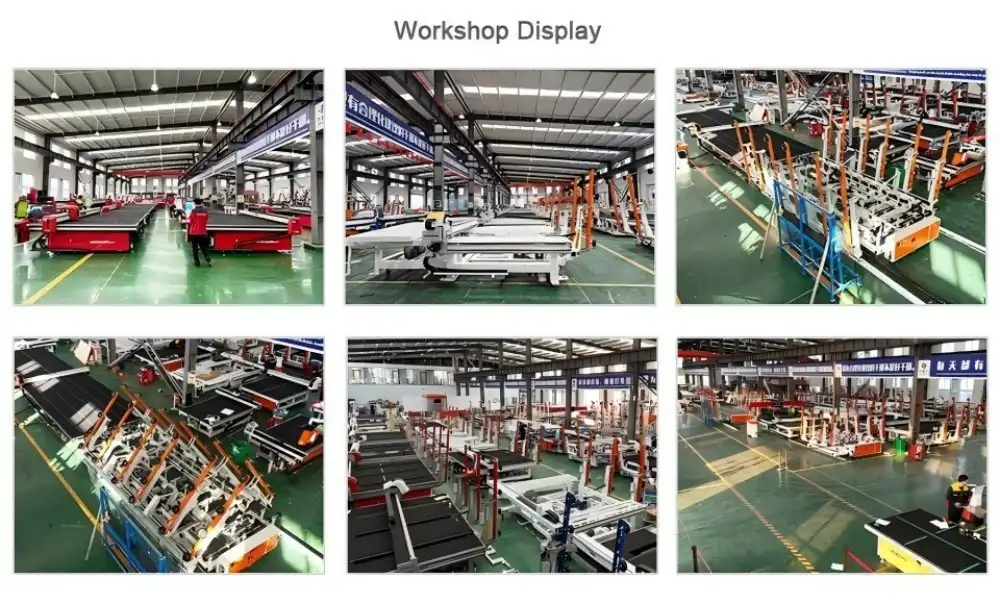

At Shandong Huashil Automation Technology Co., LTD, we specialize in creating custom glass cutting solutions that cater to the unique needs of our clients. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we are well-positioned to help you optimize your glass cutting operations. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide.

Ready to take your glass cutting capabilities to the next level? Contact our team of experts today to discuss how we can create a tailored solution for your business. Reach out to us at salescathy@sdhuashil.com and let's start crafting the perfect glass cutting table machine for your unique needs.

References

1. Johnson, A. (2022). "Advancements in Glass Cutting Technology: A Comprehensive Review." Journal of Glass Processing, 45(2), 112-128.

2. Smith, B., & Brown, C. (2021). "The Impact of Customization on Glass Manufacturing Efficiency." International Glass Industry Review, 18(4), 76-89.

3. Lee, D. et al. (2023). "Optimizing ROI in Glass Cutting Equipment: A Case Study Analysis." Journal of Industrial Engineering, 37(1), 203-217.

4. Zhang, Y. (2022). "Safety Innovations in Modern Glass Cutting Machinery." Glass Technology: European Journal of Glass Science and Technology Part A, 63(5), 189-201.