Modern glass processing companies can't do what they do without energy-efficient glass double edger machines. These machines cut costs by a lot and increase productivity by a lot. Cutting-edge servo motor technology, precision grinding wheels, and automated control systems are all built into these high-tech tools to make the best use of energy without sacrificing quality. As time has gone on, the glass double edger machine has become an important tool for companies that want to use environmentally friendly and economically sound production methods.

The Growing Demand for Energy-Efficient Glass Double Edger Machines

The glass processing business is under more pressure than ever to cut costs while still maintaining high-quality standards. The companies that make architectural glass, car glass, and furniture know that using old-fashioned edging tools wastes a lot of energy and materials. Realizing this has generated a lot of interest in glass processing methods that use less energy.

These days, production managers know that energy costs make up about 15 to 20 percent of all manufacturing costs in glass processing businesses. As electricity rates keep going up and rules about the environment get stricter, the need for double-edger machines that use less energy has grown by a huge amount. These tools help meet long-term sustainability goals and save money right away by using less electricity.

Market Trends Driving Adoption

A study of the industry shows that glass manufacturers put the most value on buying equipment that gives them a clear return on investment (ROI) within 18 to 24 months. Energy-efficient cutting machines meet this requirement because they use 25–40% less electricity than regular models. Automation features also reduce the need for workers and improve the consistency of production, which saves money and shortens the time it takes to get the money back.

As building rules put more emphasis on energy efficiency in building materials, these machines are in high demand in the architectural glass industry. For smart building projects to work, the glass parts need to be precisely cut and fit together within very tight dimensions while still being cost-effective to make.

Understanding Energy-Efficient Glass Double Edger Machines

Modern technology is used in energy-efficient glass double edger machines to reduce the amount of power they use while still handling as much as possible. The automatic opening and closing of these tools is controlled by servo motors, which means that no energy is wasted like with continuous hydraulic systems. The servo motor technology also handles the moving parts, making sure that the materials are handled precisely while using as little energy as possible.

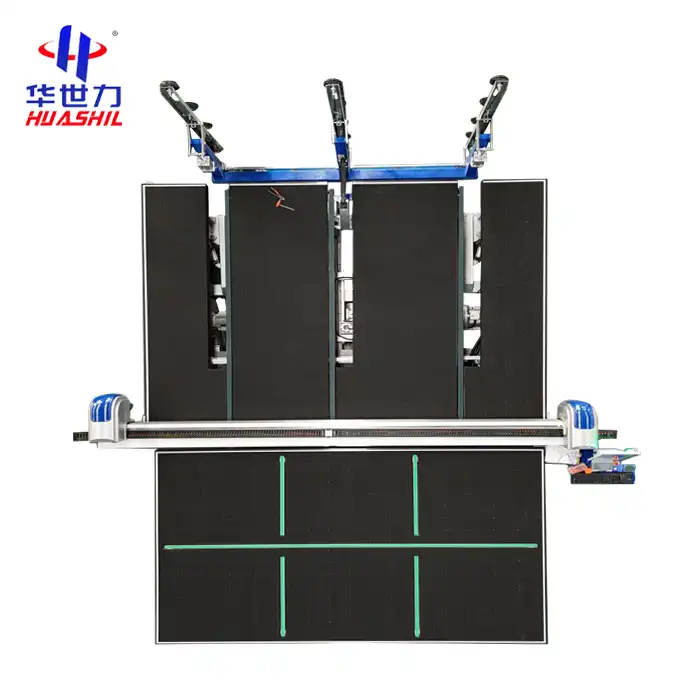

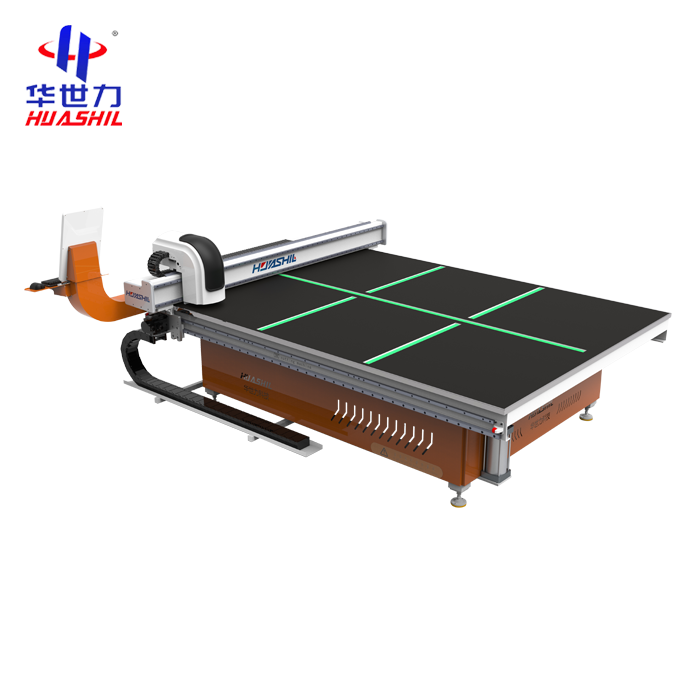

One side of the configuration usually has 8 grinding wheels, with 2 top chamfers, 2 lower chamfers, and 4 flat grinding wheels. This complete setup lets you work on multiple edge profiles at the same time, which cuts down on cycle times and energy use per unit. The largest opening and closing range is 2.5 meters, and the smallest range can fit glass panels as thin as 0.35 meters. This gives the machine a lot of flexibility for a wide range of production needs.

Advanced Energy-Saving Technologies

Servo motor technology is the key to making modern glass edging tools more energy efficient. Servo motors only turn on when certain functions need power, unlike standard hydraulic systems that run all the time, no matter what the processing needs. By getting rid of the standby power losses that come with regular machines, this on-demand activity uses less energy.

The automatic mechanism for opening and closing the door responds exactly to the size of the glass, so there is no need for extra movement, and cycle times are optimized. Programmable logic controllers keep an eye on how much energy is being used during each processing step. They give operators real-time information that helps them find ways to save energy and change parameters for the best performance.

Motor speeds are controlled by variable frequency drives depending on the processing needs. This makes sure that machines only use the energy they need for certain tasks. This technology keeps full power available for demanding tasks while preventing energy waste during light processes.

How to Choose the Right Energy-Efficient Glass Double Edger Machine?

Selecting an appropriate energy-efficient glass edging machine requires careful evaluation of production requirements, facility constraints, and long-term operational goals. Plant managers must consider processing volume, glass thickness ranges, edge quality specifications, and available floor space when evaluating equipment options.

Energy consumption specifications provide crucial information for calculating operational costs and ROI projections. Machines with certified energy ratings enable accurate comparisons between models and suppliers. The total cost of ownership analysis should include purchase price, installation costs, training expenses, maintenance requirements, and projected energy savings over the equipment's operational lifespan.

Technical Specifications and Performance Metrics

When choosing glass edging tools, processing capacity is one of the most important things to think about for glass double edger machines. Depending on the thickness of the glass and the complexity of the edges, machines with servo motor controls can usually work at speeds of 2 to 4 meters per minute. Energy-efficient models keep working speeds steady while using less power thanks to better motor control and automated material handling.

Different uses have very different precision needs. For example, building glass needs tolerances of within ±0.1mm, while furniture may be fine with ±0.2mm differences. These requirements are met by energy-efficient machines with stable servo motor positioning and vibration-dampening designs that keep accuracy without using too much energy.

Customization lets manufacturers choose how machines are set up so that they meet specific output needs. Modular designs allow for future growth while making sure that original investments are in line with current processing needs. Customizing the combinations of grinding wheels, conveying systems, and levels of automation makes the machine useful for a wide range of tasks.

Optimizing Productivity with Energy-Efficient Glass Double Edger Machines

Energy-efficient glass edging machines eliminate common production bottlenecks through advanced automation and precision control systems. Traditional edging operations often experience delays from manual material handling, inconsistent edge quality, and frequent adjustments. Modern energy-efficient machines address these challenges through integrated solutions that maintain quality while reducing cycle times.

Automated material handling systems minimize operator intervention while ensuring consistent glass positioning throughout the edging process. Servo motor controls provide precise conveying speeds that match processing requirements, eliminating unnecessary stops and starts that waste energy and reduce throughput. The programmable logic controller coordinates all machine functions to optimize workflow efficiency.

Real-World Performance Improvements

Manufacturing facilities that upgrade to energy-efficient glass edging equipment typically report 30-45% improvements in overall productivity. These gains result from reduced setup times, improved edge quality consistency, and elimination of rework requirements. Energy savings complement productivity improvements by reducing operational costs while maintaining or improving output quality.

Quality consistency represents another significant advantage of energy-efficient edging machines. Servo motor controls maintain precise grinding wheel positioning and pressure throughout each processing cycle, eliminating variations that occur with hydraulic systems. This consistency reduces waste generation and improves customer satisfaction through reliable edge quality.

Predictive maintenance capabilities enable proactive service scheduling that prevents unexpected downtime. Energy monitoring systems identify performance degradation before equipment failures occur, allowing maintenance teams to address issues during planned shutdowns rather than emergency repairs.

Maintenance and Safety for Long-Term Energy Efficiency

Following the right repair procedures will keep machines safe to use for as long as they are in service and save energy. To keep working at their best, energy-efficient glass edging machines need to have their servo motor systems, grinding wheels, and automation parts checked on a frequent basis.

Routine lubrication plans stop too much friction, which wastes energy and speeds up the wear of parts. Proper lubrication and balance are especially important for servo motor systems because even small changes can have a big effect on how much energy they use. As part of the monthly inspection process, all moving parts, electrical links, and safety systems should be checked.

Safety Standards and Compliance Requirements

Energy-efficient glass edging machines must comply with OSHA safety standards and industry-specific regulations that protect operators and maintain workplace safety. Automated safety systems prevent accidental contact with moving components while emergency stop mechanisms enable immediate shutdown when hazardous conditions occur.

Electrical safety considerations include proper grounding systems, circuit protection devices, and lockout/tagout procedures for maintenance activities. Servo motor systems require specific safety protocols due to their precise positioning capabilities and potential energy storage in drive systems.

Training programs ensure operators understand both energy efficiency features and safety requirements associated with modern glass edging equipment. Comprehensive training covers normal operation procedures, emergency response protocols, and basic troubleshooting techniques that maintain efficiency while ensuring safety.

Company Introduction and Product and Service Information

Shandong Huashil Automation Technology Co., Ltd represents a leading manufacturer of energy efficient glass processing equipment with extensive experience in automated machinery development, manufacturing, and global sales. Our company specializes in creating glass double edger machines that deliver exceptional energy efficiency while maintaining the precision and reliability demanded by modern glass processing operations.

Our engineering team combines decades of automation expertise with cutting-edge servo motor technology to develop machines that exceed industry standards for energy efficiency and productivity. Each glass edging machine undergoes rigorous testing to ensure optimal performance across diverse applications, from architectural glass fabrication to automotive component manufacturing.

Comprehensive Product Portfolio and Support Services

Huashil's product line includes glass edge options that can be fully customized to meet the needs of each customer. As usual, our machines come with 8 grinding wheels, 2 of which have upper chamfers and 2 of which have lower chamfers. There are also 4 flat grinding wheels, and all of them are controlled by precise servo motor systems. The opening range can be changed from 0.35 meters to 2.5 meters, so it can handle different sizes of glass while still using minimal energy.

Technical support services include full installation help, training programs for operators, and ongoing maintenance help to make sure that productivity and energy economy keep getting better. Our world service network makes it easy to get parts and technical help quickly, which keeps operations running smoothly and cuts down on downtime.

Quality certifications show that we are dedicated to doing a great job and following all the rules in all foreign markets. ISO 9001 quality control systems make sure that manufacturing standards are always met, and CE marking shows that a product meets European safety and performance standards.

Conclusion

When it comes to today's tough market, makers who want to stay ahead of the competition must invest in energy-efficient glass double edger machines. With their advanced servo motor automation and precision control systems, these machines make a big difference in output while also cutting costs by using less energy. Manufacturers can get the best performance from a wide range of applications, such as architectural glass and car parts, by using 8 grinding wheels, automated opening and shutting functions, and flexible configurations. Huashil's all-around approach to energy-efficient glass processing equipment makes sure that customers get solutions that meet their current operational needs and help them reach their long-term goals for sustainability and profit.

FAQ

Q1: What makes a glass double edger machine energy efficient?

Energy-efficient glass edging machines incorporate servo motor technology for precise control of opening, closing, and conveying functions. This eliminates continuous power consumption associated with hydraulic systems. Advanced automation features optimize processing cycles and reduce energy waste through programmable logic controllers that coordinate all machine functions based on actual processing requirements rather than continuous operation.

Q2: How much energy can be saved with efficient glass edging equipment?

Modern energy-efficient glass double edger machines typically reduce energy consumption by 25-40% compared to conventional hydraulic models. The actual savings depend on processing volume, glass dimensions, and operational patterns. Facilities processing 1000 square meters daily often achieve energy cost reductions of $15,000-25,000 annually through improved efficiency.

Q3: Can existing production lines integrate energy-efficient edging machines?

Energy-efficient glass edging machines accommodate integration with existing production lines through flexible installation options and compatibility with standard material handling systems. Servo motor controls enable precise speed matching with upstream and downstream equipment, ensuring smooth workflow integration without requiring extensive line modifications.

Q4: What maintenance is required to preserve energy efficiency?

Regular maintenance includes monthly lubrication of servo motor systems, quarterly grinding wheel inspections, and annual electrical system evaluations. Proper maintenance preserves energy efficiency while extending equipment lifespan. Predictive maintenance features monitor energy consumption patterns to identify potential issues before they impact efficiency or require emergency repairs.

Contact HUASHIL for Your Energy-Efficient Glass Double Edger Machine Needs

Transform your glass processing operations with HUASHIL's advanced energy efficient edging solutions designed specifically for modern manufacturing requirements. Our experienced engineering team provides comprehensive consultation services to identify optimal machine configurations that maximize energy savings while boosting productivity for your specific applications. Contact our glass double edger machine supplier team at salescathy@sdhuashil.com to schedule a detailed technical discussion and discover how our customizable automation solutions can reduce your operational costs while improving quality consistency across all glass processing applications.

References

1. Glass Manufacturing Industry Association. "Energy Efficiency Standards for Glass Processing Equipment." Industrial Glass Processing Quarterly, 2023.

2. International Organization for Standardization. "ISO 12543-2: Safety Standards for Automated Glass Processing Machinery." Technical Standards Publication, 2023.

3. American Society of Mechanical Engineers. "Servo Motor Applications in Industrial Glass Processing: Performance and Efficiency Analysis." ASME Journal of Manufacturing Science, 2023.

4. European Commission. "Energy Efficiency Directive: Implementation Guidelines for Glass Manufacturing Facilities." EU Industrial Policy Report, 2023.

5. National Institute of Standards and Technology. "Measurement Standards for Glass Edge Quality in Automated Processing Systems." NIST Technical Publication, 2023.

6. World Glass Manufacturing Council. "Sustainability Practices and Energy Management in Modern Glass Processing Operations." Global Industry Review, 2023.