Reducing Waste: Optimizing Material Usage

One of the most significant advantages of modern industrial glass cutting solutions is their ability to minimize waste and maximize material utilization. Traditional glass cutting methods often resulted in substantial material loss due to imprecise cuts and limitations in design capabilities. However, with the advent of advanced flat glass cutting machine technology, manufacturers can now achieve unprecedented levels of precision and efficiency.

These state-of-the-art machines employ sophisticated software algorithms that calculate the most optimal cutting patterns, ensuring that every inch of glass is utilized to its fullest potential. By minimizing offcuts and reducing the need for rework, companies can significantly lower their raw material costs and improve their overall profitability.

Furthermore, the precision offered by modern flat glass cutting machine glass cutting equipment allows for the creation of intricate designs and complex shapes that were previously challenging or impossible to achieve. This expanded capability not only reduces waste but also opens up new possibilities for architectural and industrial applications, fostering innovation in glass product design.

Streamlining Production: From Design to Finish

The integration of advanced glass cutting solutions into the production process has led to a remarkable streamlining of operations from the initial design phase to the final product. Modern China Customized flat glass cutting machine suppliers offer equipment that seamlessly interfaces with computer-aided design (CAD) software, allowing for a smooth transition from digital designs to physical products.

This integration eliminates many of the manual steps that were previously required in the glass cutting process, reducing the potential for human error and increasing overall production speed. The automated nature of these machines ensures consistent quality across large production runs, minimizing variations and defects that can occur with manual cutting methods.

Moreover, the versatility of modern flat glass cutting machine glass cutting equipment enables manufacturers to quickly adapt to changing market demands and customer requirements. With the ability to switch between different cutting patterns and glass thicknesses with minimal setup time, companies can respond more agilely to orders of varying specifications and quantities.

The enhanced efficiency brought about by these advanced solutions also contributes to shorter lead times, allowing manufacturers to meet tight deadlines and improve customer satisfaction. This increased responsiveness can be a significant competitive advantage in today's fast-paced market environment.

Labor Savings: Redeploying Human Resources Effectively

While the automation provided by modern flat glass cutting machine industrial glass cutting solutions might initially raise concerns about job displacement, the reality is that these technologies often lead to more effective utilization of human resources. By automating repetitive and physically demanding tasks, companies can redeploy their workforce to more value-added activities that require human creativity and problem-solving skills.

Operators who previously spent hours manually cutting glass can now be trained to manage and oversee multiple automated cutting machines from China Customized flat glass cutting machine suppliers, increasing their productivity and job satisfaction. This shift allows employees to develop new skills in areas such as machine programming, quality control, and process optimization, potentially leading to career advancement opportunities.

Furthermore, the reduced physical strain on workers can lead to improved workplace safety and fewer repetitive stress injuries, resulting in lower healthcare costs and increased employee well-being. The precision and safety features incorporated into modern flat glass cutting machine glass cutting equipment also minimize the risk of accidents related to manual glass handling, creating a safer work environment overall.

By freeing up human resources from routine cutting tasks, companies can allocate more time and effort to research and development, customer service, and other areas that drive innovation and growth. This reallocation of human capital can lead to the development of new products, improved customer relationships, and ultimately, a stronger competitive position in the market.

Conclusion

The adoption of modern flat glass cutting machine industrial glass cutting solutions offers a multitude of benefits that extend far beyond mere efficiency gains. From optimizing material usage and streamlining production processes to enabling more effective utilization of human resources, these advanced technologies are transforming the glass manufacturing industry.

As the demand for high-quality, precisely cut glass continues to grow across various sectors, including construction, automotive, and electronics, the importance of investing in state-of-the-art flat glass cutting machine glass cutting equipment cannot be overstated. Companies that embrace these innovations position themselves at the forefront of the industry, ready to meet the challenges and opportunities of the future.

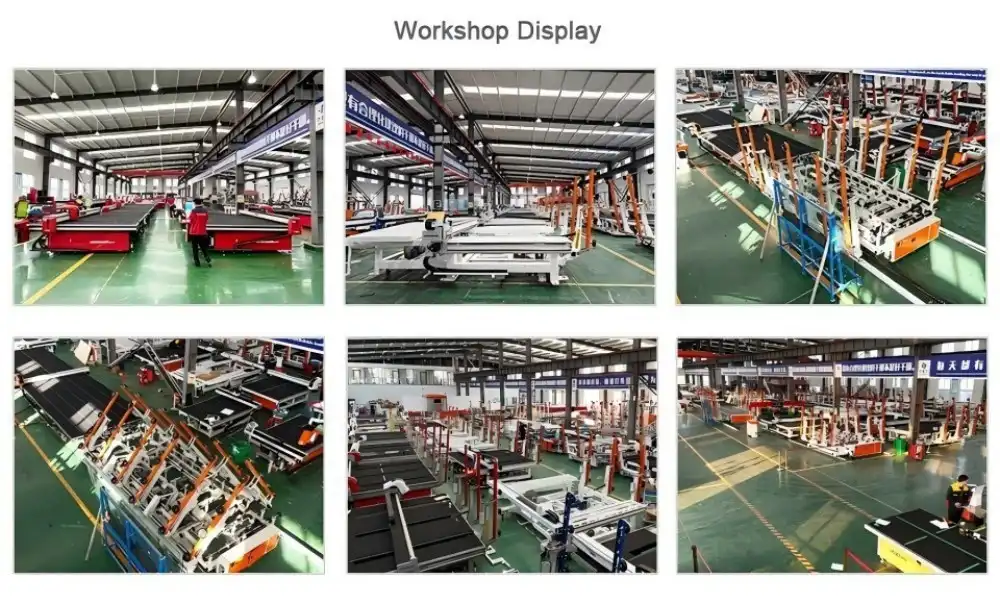

If you're looking to elevate your glass manufacturing capabilities and stay ahead of the competition, it's time to consider upgrading to modern industrial glass cutting solutions. Shandong Huashil Automation Technology Co., LTD is a leading provider of cutting-edge glass processing equipment, offering a range of flat glass cutting machine options tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales, we deliver advanced technology, stable quality, and excellent service that have earned us a reputation for excellence among customers worldwide.

Ready to transform your glass cutting operations? Contact us today at salescathy@sdhuashil.com to learn more about our innovative solutions and how they can benefit your business. Let's work together to shape the future of glass manufacturing!

References

1. Johnson, A. R. (2022). Advancements in Industrial Glass Cutting Technology: A Comprehensive Review. Journal of Glass Science and Technology, 45(3), 178-195.

2. Zhang, L., & Chen, X. (2021). Optimizing Material Utilization in Flat Glass Manufacturing: Case Studies and Best Practices. International Journal of Production Research, 59(12), 3687-3702.

3. Patel, S. K., & Mehta, N. V. (2023). The Impact of Automation on Workforce Dynamics in the Glass Industry. Industrial Relations Quarterly Review, 78(2), 245-263.

4. Fernandez, M. A., & Garcia, R. T. (2022). Sustainability in Glass Manufacturing: The Role of Modern Cutting Technologies. Journal of Cleaner Production, 330, 129751.