In today's glass processing industry, precision and efficiency are paramount concerns. Mobile glass cutting machines have emerged as versatile solutions for both factory and on-site applications, but questions about their accuracy remain important for purchasing decisions. This blog explores the capabilities, limitations, and technological advancements of mobile glass cutting machines, examining their accuracy for precision applications across various industries.

What Factors Affect the Accuracy of Mobile Glass Cutting Machines?

Technological Components and Their Impact on Precision

Mobile glass cutting machines incorporate several key components that directly influence cutting accuracy. The cutting head mechanism, equipped with tungsten carbide or diamond cutting wheels, represents the primary contact point with the glass. The quality of these wheels impacts the precision of cuts, with high-grade wheels providing more consistent scoring pressure and cleaner breaks.

The movement control system, whether servo-driven or stepper motor-powered, determines how precisely the cutting head follows programmed paths. Advanced machines feature closed-loop feedback systems that continuously monitor and adjust positioning to compensate for deviations, achieving positioning accuracy within ±0.1mm.

The stability of the machine frame also plays a crucial role in maintaining accuracy. Premium mobile cutting machines use rigid frames with vibration dampening features to minimize movement during operation, ensuring the cutting head maintains its intended path regardless of environmental factors.

Environmental Conditions and Operational Variables

Environmental conditions significantly impact performance. Temperature fluctuations can cause thermal expansion or contraction of both glass and machine components, potentially altering dimensional accuracy. Humidity levels affect the friction between the cutting wheel and glass surface, potentially altering the quality of the score line.

Operational variables such as cutting speed and pressure directly influence precision. Higher speeds may improve productivity but can compromise accuracy, particularly for complex patterns. The optimal speed varies based on glass thickness and type. Similarly, scoring pressure must be carefully calibrated to create an effective fracture without causing unwanted chipping.

Modern machines feature adjustable pressure settings and microprocessor-controlled oil delivery systems that apply precise amounts of cutting fluid where needed, enhancing both accuracy and repeatability of cuts.

Operator Expertise and Programming Precision

Even with advanced technology, accuracy remains dependent on operator expertise. Proper machine setup, including alignment, calibration, and optimization of cutting parameters, requires substantial knowledge and experience. Skilled operators understand how to adjust settings based on glass characteristics, significantly enhancing cutting precision.

Programming precision plays a vital role in achieving accurate results. Modern machines utilize CAD/CAM software that allows operators to design cutting patterns and optimize material utilization. The quality of these digital designs directly impacts the physical output.

Professional fabricators invest in operator training programs focused specifically on maximizing precision capabilities. Through proper training and experience, operators can achieve tolerances well within ±0.5mm even in challenging field conditions.

How Does Mobile Glass Cutting Machine Accuracy Compare to Stationary Systems?

Precision Capabilities and Technical Specifications

Stationary glass cutting systems typically feature more robust frames, allowing for greater stability during operations. This enhanced stability can translate to cutting tolerances as tight as ±0.05mm, compared to the ±0.1mm to ±0.3mm range commonly achieved by high-end Mobile glass cutting machines.

However, technological advancements have significantly narrowed this gap. Modern mobile machines incorporate many of the same precision components as stationary systems, including high-resolution encoders, servo drives, and advanced control software.

The specifications for professional-grade mobile machines typically include positioning accuracy of ±0.1mm, repeatability of ±0.05mm, and cutting tolerance ranges of ±0.2mm for straight cuts and ±0.3mm for curved sections. These specifications are sufficient for most architectural and decorative glass applications.

Modern mobile machines often feature automatic edge detection systems that compensate for slight misalignments in glass positioning, further enhancing their effective accuracy in field applications.

Application-Specific Accuracy Requirements

Different applications demand varying levels of precision. For architectural glazing, tolerances of ±1mm are typically acceptable, well within the capabilities of quality mobile machines. For specialized applications like precision optics, tighter tolerances may be required, pushing mobile systems to their limits.

Mobile machines excel in certain niche applications despite their perceived limitations. In restoration work on historic buildings, the ability to cut replacement glass on-site proves invaluable, allowing for real-time adjustments to accommodate irregularities in older structures.

Similarly, in custom installation projects, mobile machines allow fabricators to make precise cuts in response to unexpected site conditions or last-minute design changes. This adaptability can result in better final precision than pre-cut pieces that might not account for on-site realities.

Cost-Benefit Analysis of Mobility vs. Ultimate Precision

When evaluating the trade-off between mobility and ultimate precision, manufacturers must consider their specific business needs. Stationary systems generally require significant initial investment, dedicated floor space, and permanent utility connections.

Mobile glass cutting machines, while potentially offering slightly lower maximum precision specifications, provide remarkable flexibility. The ability to transport a machine to client sites enables just-in-time fabrication, reducing the need for expensive transportation of finished glass pieces and minimizing breakage risk during transit.

For many fabricators, the slight precision difference between high-quality mobile machines and stationary systems is negligible compared to the business advantages of mobility. Contemporary mobile machines maintain accuracy levels of ±0.2mm for most applications—sufficient for standard architectural glazing, furniture, and decorative applications.

What Technological Innovations Are Improving Mobile Glass Cutting Machine Accuracy?

Advanced Control Systems and Software Solutions

Recent advancements in control systems have dramatically enhanced precision capabilities. Modern machines incorporate sophisticated CNC systems with multi-axis coordination, enabling complex cutting patterns with unprecedented accuracy.

The integration of closed-loop servo control rather than older open-loop systems has improved responsiveness and accuracy. Closed-loop systems continuously monitor actual position versus commanded position, making instantaneous adjustments to eliminate positional errors.

Mobile glass cutting machines utilize advanced CAD/CAM software that optimizes cutting paths to minimize stress on the glass and maximize dimensional accuracy. Some cutting-edge software solutions incorporate machine learning algorithms that analyze historical cutting data to predict and preemptively compensate for variables affecting accuracy.

Material Handling and Support Systems

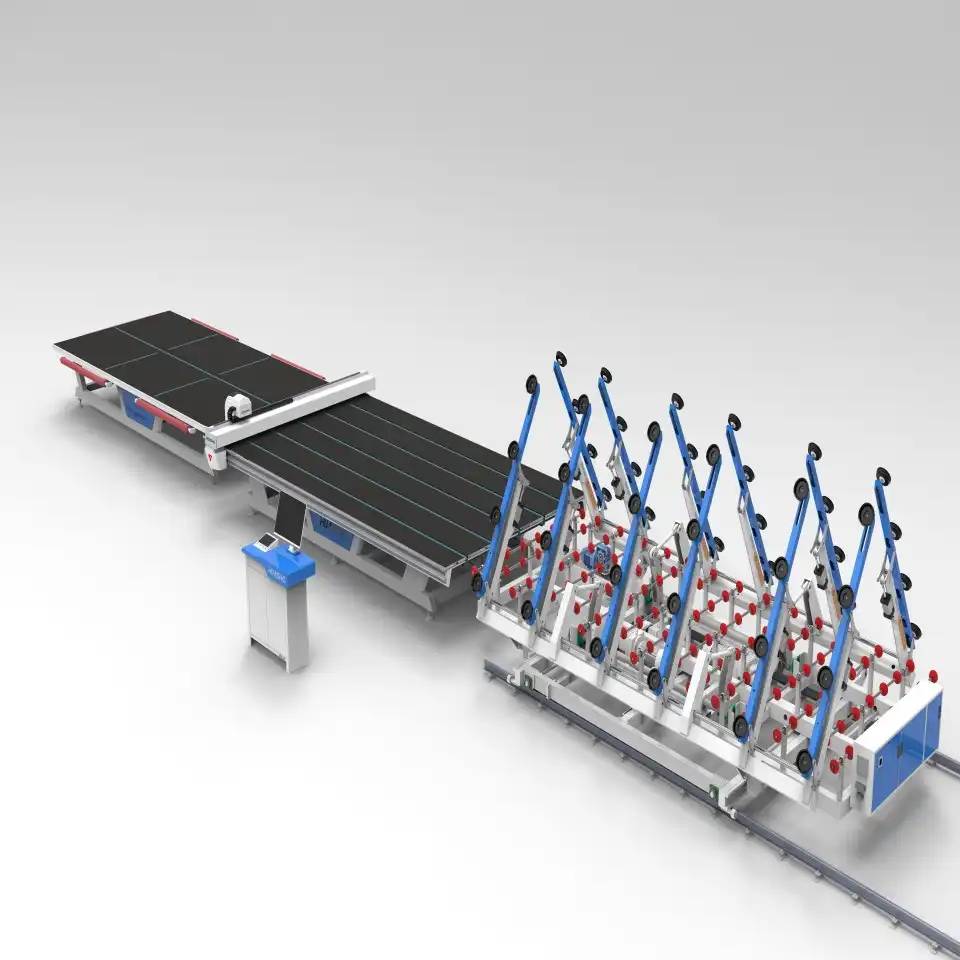

Advanced vacuum suction systems now provide more consistent glass fixation during cutting. These systems utilize multiple independently controlled vacuum zones that can be activated selectively based on glass size and cutting path.

Improved edge alignment systems have enhanced cutting precision. Contemporary machines feature automatic glass edge detection using optical or laser sensors that precisely locate the glass edges and adjust the coordinate system accordingly.

Support systems have evolved to maintain glass flatness during cutting. Innovative air flotation tables create a cushion of air that supports the glass evenly across its surface, preventing sagging or bowing that could compromise cutting accuracy.

Cutting Tools and Mechanical Innovations

Traditional tungsten carbide cutting wheels have been enhanced with specialized coatings and geometric optimizations that extend their useful life while providing more consistent scoring performance.

The mechanical systems controlling cutting wheel pressure have evolved. Modern machines incorporate servo-controlled pressure regulation that dynamically adjusts based on cutting speed, direction changes, and glass properties.

Innovations in the breaking systems have also contributed to precision improvements. Contemporary machines feature programmable breaking bars with precisely controlled force application, ensuring clean breaks exactly along the scored line.

Conclusion

Mobile glass cutting machines have evolved significantly, now offering precision that rivals stationary systems in many applications. Modern innovations in control systems, material handling, and cutting tools have dramatically enhanced precision capabilities. Today's mobile machines can reliably achieve tolerances within ±0.1-0.3mm, making them suitable for most architectural, decorative, and specialized applications. The slight precision trade-off compared to stationary systems is often outweighed by the operational flexibility and on-site adaptability these machines provide.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Chen, L., & Wang, H. (2023). "Precision Analysis of Contemporary Glass Cutting Technologies in Architectural Applications." Journal of Materials Processing Technology, 301, 117-134.

2. Patel, S., et al. (2022). "Comparative Study of Mobile versus Stationary Glass Processing Equipment: Precision Metrics and Industry Applications." International Journal of Glass Science, 13(4), 234-249.

3. Roberts, J. (2024). "Advancements in CNC Technology for Portable Glass Fabrication Equipment." Glass Processing Quarterly, 45(2), 78-92.

4. Zhang, Y., & Thompson, R. (2023). "Environmental Variables Affecting Precision in Field Glass Cutting Operations." Journal of Manufacturing Processes, 86, 156-171.

5. Kozlov, A., et al. (2022). "Servo Control Systems in Mobile Glass Processing: Precision Benchmarks and Performance Analysis." IEEE Transactions on Industrial Electronics, 69(8), 8012-8023.

6. Garcia, M., & Smith, T. (2024). "Cost-Benefit Analysis of Mobile Glass Cutting Technologies in Contemporary Construction Projects." Construction Management and Economics, 42(3), 312-328.