An automatic glass loading machine fundamentally changes how glass is made by getting rid of bottlenecks caused by people handling the glass and cutting production cycle times by a huge amount. These high-tech devices employ advanced control and precision robots to transfer glass sheets from storage areas to processing stations without any difficulties. This increases throughput by up to 50% and nearly totally prevents damage to the products. Modern automated loading solutions use modern sensors, vacuum handling systems, and programmable controls to make sure that glass is handled consistently and reliably in a wide range of manufacturing settings. These solutions are vital for glass production facilities that wish to stay competitive.

Understanding Automatic Glass Loading Machines: Advanced Technology at Work

Modern glass loading automation is the result of combining great mechanical engineering with smart control systems. These machines work by moving in a way that perfectly handles glass sheets of all sizes, from normal architectural standards to specialty ones up to 3660×2440mm. This allows them to meet the needs of modern industry.

Three basic parts that operate perfectly together make up the core technology of these systems. Three large arms on advanced automatic loading systems are set up to equally distribute weight over glass surfaces. This stops stress concentrations that could cause breaking. Each arm has precision-engineered gripper systems that adapt to changing glass thicknesses and surface treatments, enabling secure handling throughout the loading process.

The air floating system is another important new feature that makes modern loading machines different from older handling equipment. This method makes a cushion of compressed air behind glass sheets, which lowers friction and lets things slide smoothly across loading surfaces without damaging them. The air flotation mechanism is especially useful for moving huge pieces of architectural glass or fragile decorative items that could be ruined by scratches on the surface.

The ability to walk in all directions gives production line layouts more flexibility than ever before. These mobile machines may move across complicated production settings and reach many processing stations and storage locations without the need for large conveyor installations, unlike fixed-position loading systems. This mobility is quite useful for facilities that work with different types of glass or that don't have a lot of room.

Comparing Automatic and Manual Glass Loading: The Clear Advantage

Handling glass by hand in the traditional way creates many operational problems that affect both the safety of workers and the profitability of manufacturing. When handling huge sheets of glass by hand, you usually need more than one person to do it, which makes it harder to coordinate and costs more in labor. Workers are always at danger of cuts, back injuries, and repetitive strain syndromes, which can lead to insurance claims and lost productivity.

It's also tougher to be consistent with speed and accuracy when you load by hand. Even the best operators can't get the timing right as well as automated systems can. This might cause delays in manufacturing and make work flow unevenly. When glass is handled by hand, it normally breaks between 2% and 5% of the time. This implies that a lot of materials are wasted and it takes longer to bring products to customers.

Automated glass handling systems, such as the automatic glass loading machine, solve these concerns by always working the same manner. Data from manufacturers of architectural glass show that automation decreases the time it takes to handle each sheet by 60–70%. This allows facilities to handle a lot more units throughout each shift. When loading, robotic handling is so exact that it nearly never destroys anything. When systems are properly calibrated, the rate of damage drops below 0.5%.

Another huge advantage of automation is that it makes sure that quality stays the same. Automated systems insert glass sheets in the appropriate spot with millimeter-level accuracy, ensuring sure they are exactly lined up for the next steps, which could be cutting, edging, or coating. This level of accuracy speeds up the process and makes the end result better. This is especially crucial for architectural glass, since the success of the installation depends on how accurate the proportions are.

Key Features That Drive Manufacturing Excellence

Modern glass loading automation has a number of innovative features that are meant to make operations as efficient and reliable as possible. Manufacturers can choose the solutions that best meet their production needs and growth goals if they know what these capabilities are.

Customization options are a key benefit for producers who sell to a wide range of customers. Modular design concepts allow leading systems to work with different manufacturing line setups, glass specs, and facility limits. With custom programming, operators can set particular handling parameters for different types of glass. The system will then automatically change the vacuum pressure, movement speed, and positioning accuracy to meet the needs of each product.

Integrated safety systems keep both people and equipment safe by using numerous layers of monitoring. Advanced sensor networks can find out where glass is, how well equipment is working, and any possible dangers. They will automatically stop operations if something goes wrong. Safety light curtains keep people from accessing operational zones while the machine is running, and emergency stop feature makes sure that safety concerns are dealt with right away.

Energy-saving features help the environment and lower operating costs at the same time. Modern loading systems make the best use of compressed air, use less electricity when they're not in use, and have regenerative braking systems that store energy as the vehicle slows down. These advances in efficiency usually cut energy use by 20 to 30 percent compared to prior automation technology.

Real-time monitoring and diagnostic tools make it possible to do maintenance before problems happen and maintain performance at its best. Sensors built into the system keep an eye on things like operating parameters, cycle counts, and performance indicators. This lets you know about possible problems before they affect production. Technical support personnel can detect problems and offer remedies without having to go to the site thanks to remote monitoring.

Selecting the Right System for Your Manufacturing Needs

To choose the best way to automate glass loading, you need to carefully think about your production needs, the limitations of your facility, and your goals for long-term expansion. Successful selection methods take into account a number of things that affect both short-term operational gains and long-term growth potential.

Requirements for production capacity are the basis for choosing a system. To make sure that the systems they choose will fulfill both their present and future needs, manufacturers should look at current throughput needs, peak production times, and expected growth. High-volume architectural glass makers need different skills than specialist furniture makers. For example, the speed at which they can load glass, the amount of the glass they can handle, and how well they can integrate automation all differ.

When planning for facility integration, you need to think about both the expenses of installation and how well the system will work. The way the manufacturing line is set up, the power infrastructure, and the amount of space available all affect the choices for system setup. Modern loading systems can be installed in a variety of ways, but to get the best performance, you need to carefully organize the flow of materials and the needs of the operators.

When planning for facility integration, you need to think about both the expenses of installation and how well the system will work. The way the manufacturing line is set up, the power infrastructure, and the amount of space available all affect the choices for system setup. Modern loading systems, such as the automatic glass loading machine, can be installed in a variety of ways, but to get the best performance, you need to carefully organize the flow of materials and the needs of the operators.

When doing a total cost of ownership analysis, you should look at the original purchase price, installation costs, training needs, and continuing maintenance costs. Even though premium systems may cost more up front, they frequently save money in the long run by being more reliable and efficient, which leads to improved productivity and lower operating expenses.

Safety and Compliance in Glass Loading Automation

Safety is the most important thing to think about while automating the handling of glass, since huge, fragile materials and powerful mechanical systems can be very dangerous. Comprehensive safety measures protect people, equipment, and products while making sure that the rules for workplace safety are followed.

Automated technologies make it much less likely that workers will be directly exposed to the dangers of handling glass. Workers who do traditional manual loading have to lift, carry, and position large glass sheets, which can lead to cuts, crushing injuries, and musculoskeletal illnesses. Automation gets rid of direct touch with glass edges and cuts down on the repetitive lifting actions that cause injuries at work.

Advanced safety control systems have several layers of protection built in to keep accidents and damage to equipment from happening. Pressure-sensitive floor mats can tell when people are in operational zones and will stop equipment from moving until the areas are clear. Light curtains make invisible walls around the edges of equipment. If someone breaks through them, the equipment can be turned off right away.

All staff should have clear written instructions for how to respond to emergencies and practice them often. Operators need to know how to properly shut down machines, where to stop them in an emergency, and how to report safety incidents. Regular safety training keeps staff up to date on best practices and rules.

To follow industry safety standards, you need to keep an eye on equipment certification, inspection schedules, and paperwork requirements. Regular safety audits find any dangers and make sure that the rules are still being followed. Keeping accurate records of safety procedures, training sessions, and incidents shows that you care about safety at work and following the rules.

Conclusion

Automatic glass loading machines represent essential technology for modern glass manufacturing operations seeking improved efficiency, safety, and competitiveness. Through advanced automation featuring precision handling mechanisms, air floating systems, and customizable configurations, these systems deliver substantial productivity improvements while reducing operational risks and costs. The combination of reduced labor requirements, virtually eliminated breakage rates, and consistent processing quality provides compelling return on investment for facilities processing diverse glass products. As manufacturing demands continue evolving, automated loading technology offers the flexibility and reliability necessary for sustained success in competitive global markets.

Frequently Asked Questions

Q1: How much improvement in production efficiency can be expected from implementing an automatic glass loading machine?

A: Most manufacturers experience efficiency improvements of 40-60% after implementing automated glass loading systems. These improvements result from faster cycle times, reduced handling errors, and elimination of manual loading bottlenecks. Specific gains depend on current manual processes, glass sizes handled, and production volume, but payback periods typically range from 12-18 months through labor savings and increased throughput.

Q2: Can automatic glass loading machines handle different glass types and sizes within the same production run?

A: Modern automated loading systems accommodate diverse glass specifications through programmable control systems and adjustable handling mechanisms. Systems can be programmed with multiple handling profiles for different glass types, thicknesses, and sizes up to 3660×2440mm. Quick changeover capabilities allow operators to switch between glass specifications with minimal production delays, making these systems suitable for custom glass manufacturers serving varied markets.

Q3: What maintenance requirements should be expected for automatic glass loading equipment?

A: Maintenance requirements for quality automated systems are generally minimal, focusing on routine inspections, lubrication, and sensor calibration. Daily checks require approximately 15 minutes per shift, while weekly maintenance takes 2-3 hours. Annual maintenance costs typically represent 3-5% of initial equipment investment. Proper maintenance protocols, combined with quality component design, ensure reliable operation for 10-15 years with minimal major repairs.

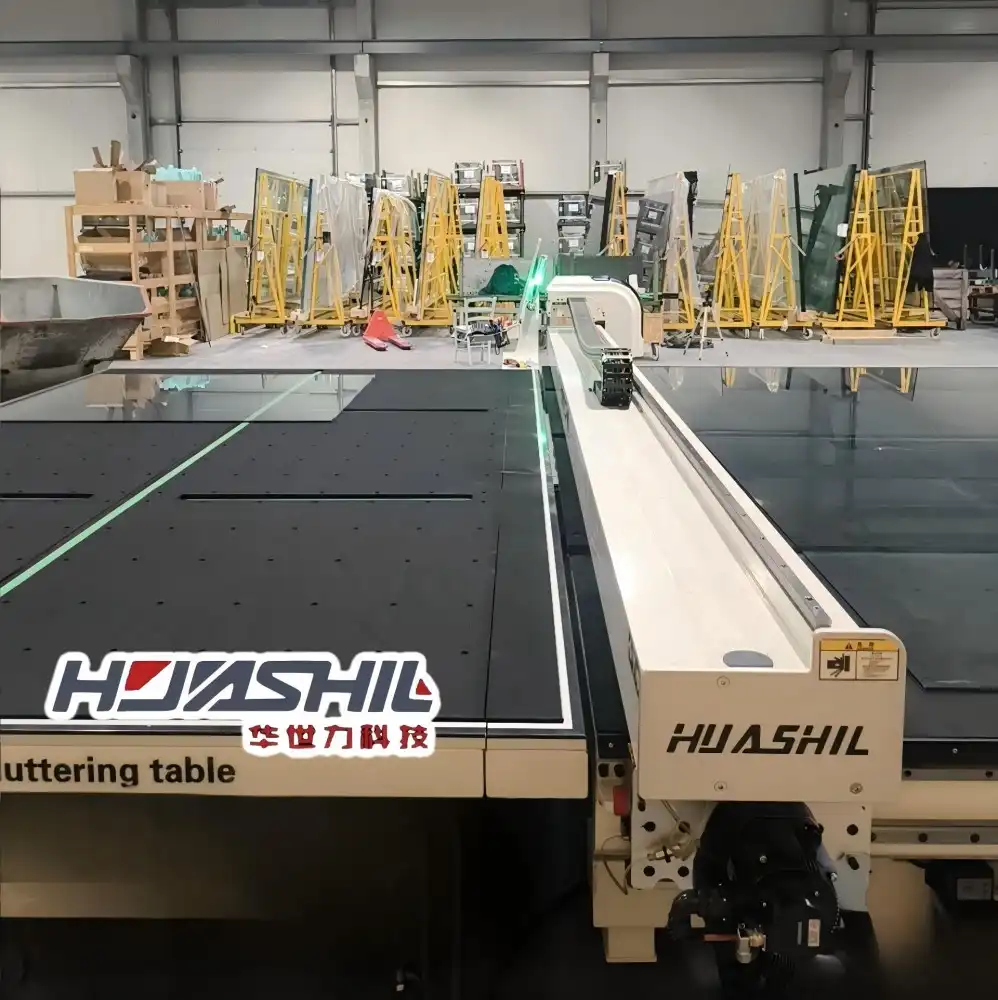

Experience Enhanced Glass Manufacturing Efficiency with HUASHIL

HUASHIL's advanced automatic glass loading machine delivers exceptional performance improvements for glass manufacturing operations seeking competitive advantages through automation. Our precision-engineered systems combine innovative three-arm loading technology with sophisticated air floating mechanisms to handle glass sheets up to 3660×2440mm with unmatched accuracy and safety.

Shandong Huashil Automation Technology Co., LTD brings decades of manufacturing expertise and global export experience to every installation. Our automated glass handling solutions feature complete customization capabilities, 360-degree mobility, and comprehensive safety systems designed specifically for demanding production environments. Whether you operate an architectural glass facility, furniture manufacturing plant, or specialized glass processing operation, our engineering team develops tailored solutions that maximize your operational efficiency.

As a leading automatic glass loading machine supplier, HUASHIL provides complete turnkey solutions including installation, operator training, and responsive technical support. Our commitment to quality engineering and customer success ensures optimal return on automation investments through improved productivity, reduced labor costs, and enhanced workplace safety.

Ready to transform your glass manufacturing operations with proven automation technology? Contact us at salescathy@sdhuashil.com to discuss your specific requirements and receive a customized proposal. Visit huashil.com to explore our complete range of glass processing automation solutions designed to elevate your manufacturing capabilities.

References

1. Industrial Automation Review. "Glass Manufacturing Automation: Trends and Technologies for Enhanced Production Efficiency." Manufacturing Technology Quarterly, 2024.

2. Glass Industry Research Institute. "Comparative Analysis of Manual vs. Automated Glass Handling Systems: Performance and Safety Metrics." Journal of Glass Manufacturing Technology, 2024.

3. Manufacturing Safety Council. "Workplace Safety Improvements Through Glass Handling Automation: A Comprehensive Industry Study." Occupational Safety and Health Engineering, 2024.

4. International Glass Manufacturing Association. "Economic Impact Assessment of Production Line Automation in Architectural Glass Manufacturing." Global Glass Industry Report, 2024.