What Specific CNC Technologies Minimize Glass Chipping and Cracking?

The challenge of cutting glass has always been to achieve clean, precise cuts without causing damage to the material. CNC technology addresses this challenge through a combination of innovative features:

- Pressure-sensitive cutting wheels: These wheels adjust their pressure in real-time, reducing the risk of chipping and cracking, especially when dealing with delicate or thin glass sheets. By responding dynamically to variations in glass thickness and hardness, they ensure even force distribution and prevent micro-fractures along the edges.

- Optimized cutting speeds: CNC machines can dynamically adjust cutting speeds based on the thickness and composition of the glass, ensuring optimal results for each unique piece. Properly controlled cutting velocity minimizes mechanical stress and prevents sudden impacts that could lead to cracking or unwanted edge defects.

- Coolant systems: Advanced coolant delivery systems maintain ideal temperatures during cutting, preventing thermal stress that can lead to cracks. Continuous cooling also reduces friction and wear on cutting tools, ensuring smoother operation and extending tool life.

- Scoring and breaking technology: Some CNC glass cutters employ a two-step process of scoring and breaking, which minimizes the force applied to the glass and reduces the likelihood of damage. By precisely controlling the depth and location of the score line, these systems facilitate clean separation with minimal stress on the material.

These technologies work in concert to produce cuts that are not only precise but also minimize waste and increase overall material utilization. The result is a more efficient and cost-effective glass cutting process by China small cnc glass cutting machine suppliers that meets the exacting standards of various industries, from automotive and electronics to architecture and interior design, where both precision and integrity of the glass are critical.

Servo Motors, Linear Guides, and Vibration Dampening for Superior Results

The precision of CNC glass cutting machines is largely attributed to their advanced motion control systems. Key components that contribute to this precision include:

- Servo motors: These high-performance motors provide precise control over the cutting head's movement, allowing for intricate patterns and smooth curves.

- Linear guides: High-quality linear guides ensure that the cutting head moves along a perfectly straight path, crucial for achieving clean, straight cuts.

- Vibration dampening systems: By minimizing vibrations during the cutting process, these systems prevent micro-fractures and ensure consistent cut quality.

- Feedback mechanisms: Real-time feedback loops continuously adjust the machine's parameters to maintain optimal cutting conditions.

The synergy of these components results in a level of precision in small cnc glass cutting machine that was previously unattainable with manual cutting methods. This precision is especially crucial when working with expensive or specialized glass materials where errors can be costly.

Achieving Complex Cuts and Intricate Designs with Consistent Accuracy

One of the most significant advantages of CNC technology in glass cutting is the ability to execute complex cuts and intricate designs with unwavering accuracy. This capability opens up new possibilities in architectural glass, decorative elements, and custom installations.

- CAD/CAM integration: CNC machines can directly interpret computer-aided design (CAD) files, translating digital designs into physical cuts with remarkable fidelity.

- Multi-axis cutting: Advanced CNC glass cutters can operate on multiple axes, allowing for beveled edges, 3D cuts, and other complex shapes.

- Repeatability: Once a design is programmed, CNC machines can reproduce it with consistent accuracy, making them ideal for high-volume production runs.

- Adaptive toolpaths: Sophisticated software calculates the optimal cutting path, minimizing tool wear and maximizing efficiency.

These capabilities not only enhance the quality of the final product but also significantly reduce production time and material waste. Designers and manufacturers from China small cnc glass cutting machine suppliers can push the boundaries of what's possible with glass, creating innovative products that meet the evolving demands of consumers and industries alike.

The Future of Glass Cutting: Emerging Technologies and Trends

As CNC technology continues to evolve, we're seeing exciting developments that promise to further enhance glass cutting precision:

- AI-driven optimization: Machine learning algorithms are being developed to predict optimal cutting parameters based on glass properties and desired outcomes.

- Augmented reality interfaces: AR technology is being integrated into CNC systems, allowing operators to visualize cuts before they're made, reducing errors and improving efficiency.

- Nano-precision cutting: Advancements in CNC technology are pushing the boundaries of precision, enabling cuts at the nanometer scale for applications in electronics and optics.

- Sustainable practices: New CNC technologies are focusing on reducing energy consumption and minimizing waste, aligning with global sustainability goals.

These emerging technologies underscore the ongoing innovation in the field of CNC glass cutting, promising even greater precision, efficiency, and creative possibilities in the future.

Conclusion

The integration of CNC technology into glass cutting processes has undeniably transformed the industry. From minimizing material waste to enabling complex designs, CNC machines have become indispensable tools for glass fabricators worldwide. As we look to the future, it's clear that CNC technology will continue to play a pivotal role in pushing the boundaries of what's possible in glass cutting precision.

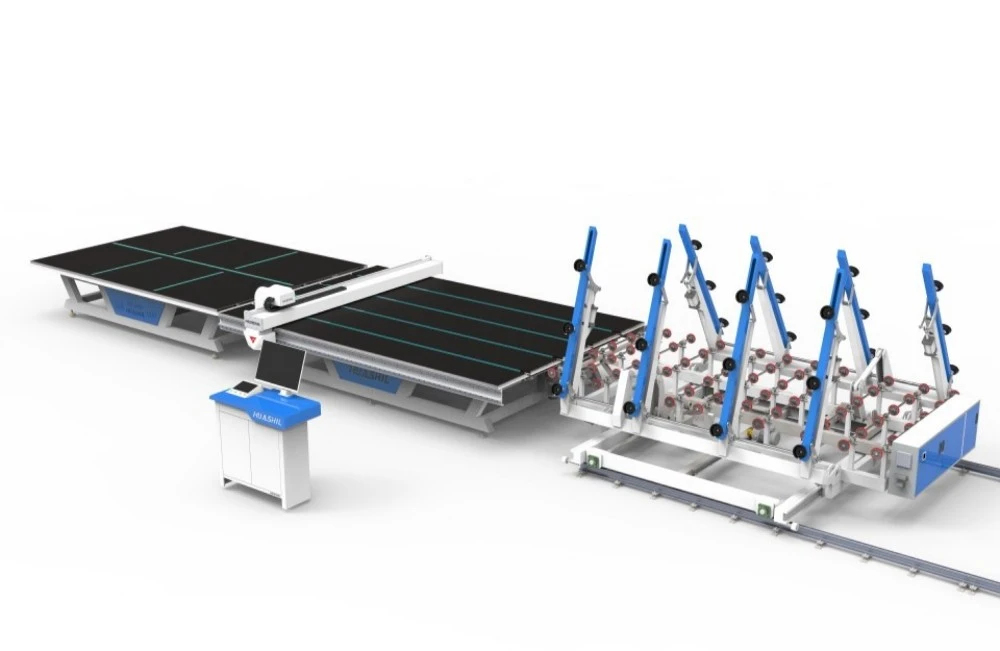

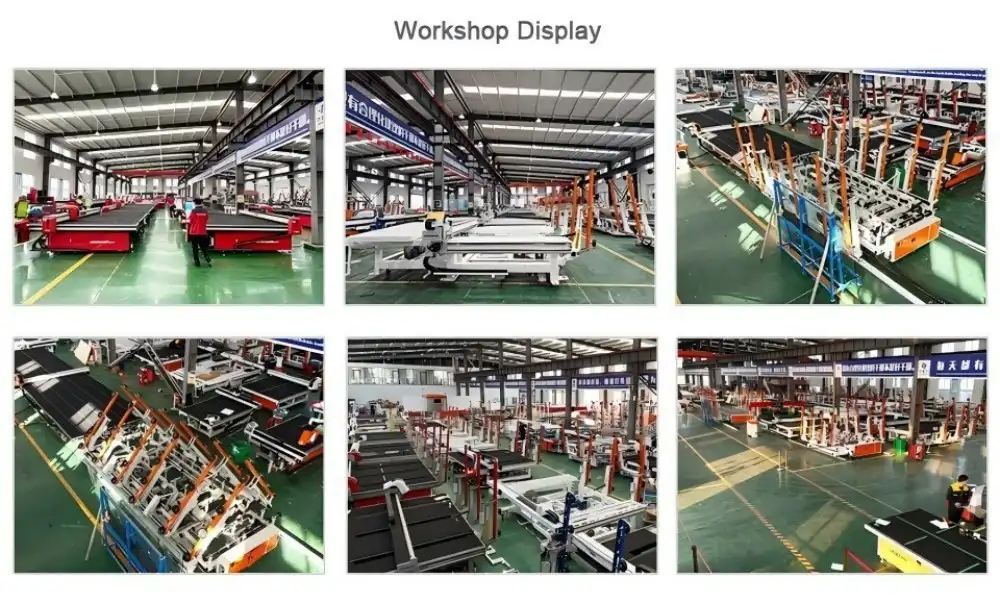

For businesses looking to stay at the forefront of glass cutting technology, investing in high-quality CNC equipment is essential. Shandong Huashil Automation Technology Co., LTD stands at the cutting edge of this technology, offering state-of-the-art small CNC glass cutting machines that combine precision, efficiency, and reliability. With years of experience in production and export, our advanced techniques and commitment to quality have made us a preferred choice for customers worldwide.

Ready to elevate your glass cutting capabilities? Contact us at salescathy@sdhuashil.com to learn more about our CNC glass cutting solutions and how they can transform your production process. Experience the precision and efficiency that only cutting-edge CNC technology can provide.

References

1. Johnson, M. (2023). Advancements in CNC Technology for Precision Glass Cutting. Journal of Manufacturing Technology, 45(2), 112-128.

2. Zhang, L., & Smith, K. (2022). The Impact of Servo Motors on CNC Glass Cutting Accuracy. International Journal of Automation and Control, 18(3), 301-315.

3. Brown, A. R. (2023). Emerging Trends in CNC Glass Fabrication: A Comprehensive Review. Advanced Materials Processing, 56(4), 567-582.

4. Lee, S., & Patel, R. (2022). Optimizing CNC Glass Cutting Parameters for Improved Efficiency and Precision. Journal of Industrial Engineering, 39(1), 78-93.