Selecting the right LOW-E glass cutting machine is a critical decision for glass processors, manufacturers, and fabrication companies. LOW-E (low emissivity) glass has become increasingly popular in modern construction due to its excellent thermal insulation properties, and processing this specialized glass requires appropriate cutting technology. This guide will help you navigate the important factors to consider when choosing a LOW-E glass cutting machine for your specific needs.

What factors should you consider when purchasing a LOW-E glass cutting machine?

Technical Specifications and Cutting Capabilities

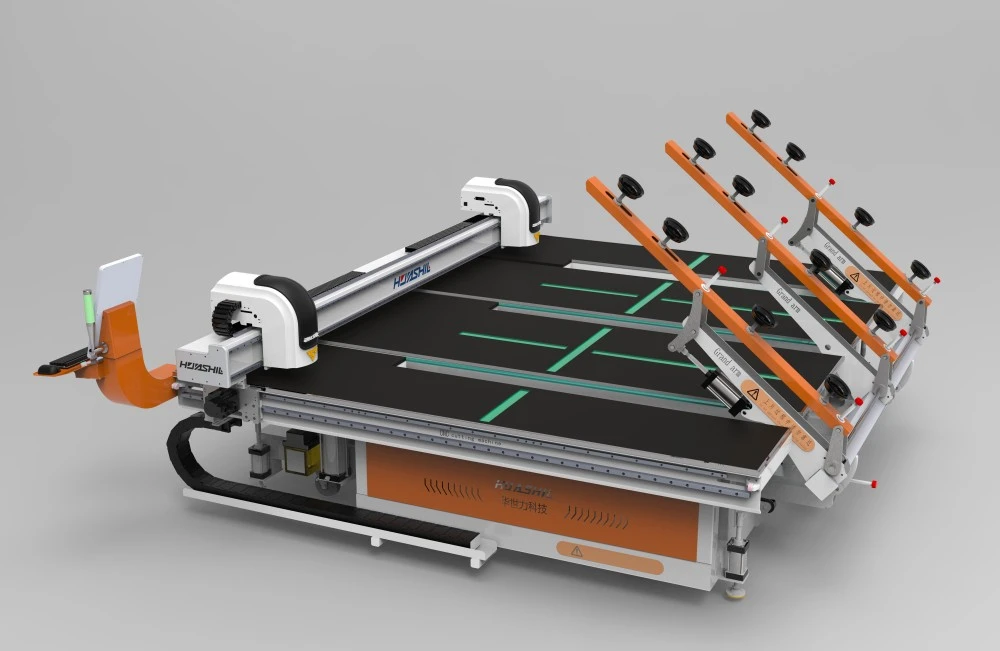

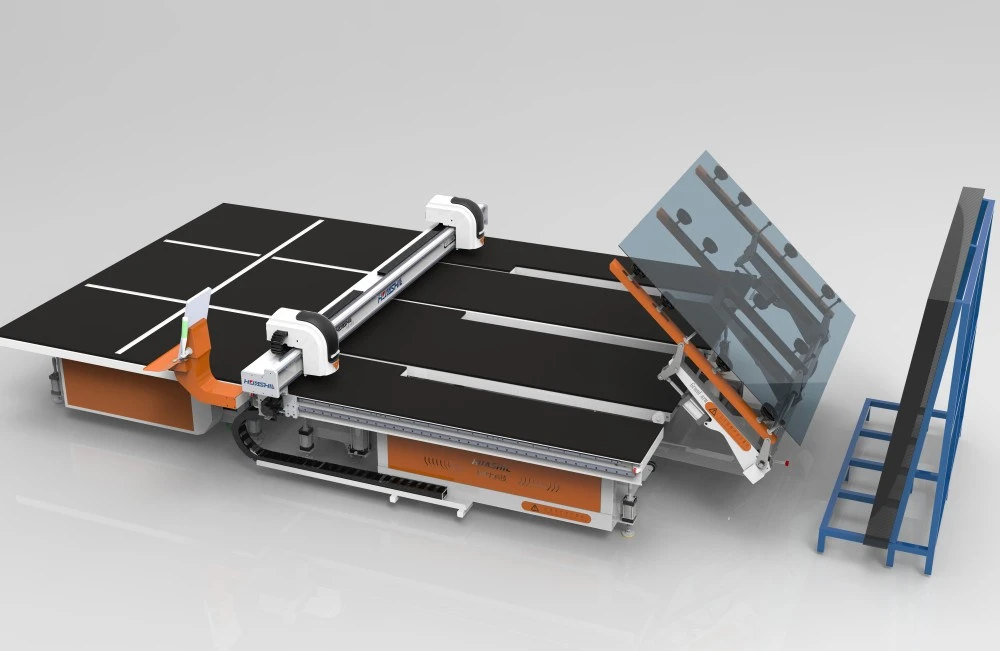

When evaluating LOW-E glass cutting machines, technical specifications should be prioritized. The cutting capabilities directly impact production efficiency and finished product quality. Modern machines offer various cutting technologies, including straight-line cutting, shape cutting, and automatic optimization systems. Consider the maximum cutting dimensions to ensure the machine can accommodate your typical glass sizes with room for growth.

Cutting speed and accuracy are crucial, particularly for precision-dependent applications such as architectural facades or energy-efficient windows. Check the machine's compatibility with different glass thicknesses, as this determines production versatility. Premium LOW-E glass cutting machines typically cut glass from 2mm to 25mm thick. Look for cutting precision within ±0.1mm to meet industry standards. Superior cutting technology reduces waste, minimizes edge defects, and preserves the integrity of the LOW-E coating.

Automation Features and Integration Capabilities

Automation is essential for maintaining competitiveness. Evaluate machines with automated loading and unloading systems to reduce manual handling and labor costs. Automatic optimization software maximizes material utilization by calculating efficient cutting patterns, particularly important for expensive LOW-E glass.

Integration capabilities create a seamless production environment. Choose machines that integrate with industry-standard CAD/CAM systems and production management software. Advanced LOW-E glass cutting machines offer barcode scanning for easy tracking throughout production. Consider machines that integrate with edge deletion, washing, and insulating glass assembly lines for comprehensive processing operations. Data collection and analysis features like Ethernet ports or IoT capabilities support continuous improvement initiatives.

Maintenance Requirements and After-Sales Support

Long-term performance depends significantly on proper maintenance and timely technical support. Investigate maintenance requirements thoroughly, looking for design features that facilitate easy access to components requiring regular attention. Machines with self-diagnostic capabilities alert operators to potential issues before causing significant downtime.

Research the manufacturer's reputation for customer service and parts availability. Leading manufacturers offer comprehensive warranty packages (12-36 months) with extension options. Consider technical support availability in your region, response times for emergency service calls, and remote diagnostics options. Training programs for operators and maintenance personnel are valuable resources. Some manufacturers offer preventive maintenance contracts, which can be cost-effective for ensuring optimal performance throughout the machine's lifespan.

How does the cost of a LOW-E glass cutting machine impact your business ROI?

Initial Investment vs. Long-term Benefits

A LOW-E glass cutting machine represents a significant capital investment, ranging from $50,000 for basic models to over $500,000 for fully automated systems. Look beyond the sticker price to consider long-term benefits. High-quality machines offer superior cutting precision, faster processing speeds, and reliable performance, translating to higher production capacity, reduced waste, and fewer rejected pieces.

Premium machines feature industrial-grade components for extended service life (10-15 years with proper maintenance). Modern LOW-E glass cutting machines incorporate energy-efficient technologies like regenerative braking systems and optimized air consumption, reducing operational costs. A 5-10% reduction in waste or 15-20% increase in throughput can generate substantial profits over the machine's lifetime. The ability to process specialized LOW-E glass with precision also opens access to higher-margin market segments.

Operating Costs and Efficiency Considerations

Consider ongoing operating costs for accurate budget planning. Energy-saving features in advanced machines can reduce energy costs by 15-30% compared to older models. Consumable expenses include cutting wheels, lubricants, and replacement parts. Premium cutting wheels for LOW-E glass cost more initially but offer extended life and superior edge quality.

Automation reduces labor costs and minimizes operator errors. Material utilization efficiency directly impacts profitability, with advanced optimization software improving utilization by 3-8%. Modern machines can increase throughput by 20-40% compared to previous-generation equipment, lowering per-piece production costs. Production flexibility—the ability to quickly transition between different glass types and cutting patterns—minimizes downtime and maintains high overall equipment effectiveness.

Financing Options and Depreciation Strategies

Various financing options make advanced LOW-E glass cutting machines accessible. Traditional equipment loans offer 3-7 year terms, while leasing requires minimal down payment with options to upgrade at lease-end. Some manufacturers offer in-house financing with customized payment structures.

Strategic tax planning yields significant benefits. Capital equipment often qualifies for accelerated depreciation, allowing faster write-offs against taxable income. In the US, Section 179 deductions enable qualifying businesses to deduct the full purchase price in the acquisition year, up to certain limits. Some regions offer tax incentives for energy-efficient manufacturing equipment. When comparing financing scenarios, consider total ownership cost, including interest, tax implications, and potential residual value.

What technological innovations should you look for in modern LOW-E glass cutting machines?

Cutting-Edge Control Systems and Software

Modern LOW-E glass cutting machines feature sophisticated CNC control systems with intuitive interfaces that simplify operation. Multi-touch screens offer gesture control similar to tablets, providing intuitive operation and faster learning curves. Control software should include comprehensive glass libraries with predefined parameters for different LOW-E glass types, automatically adjusting cutting pressure, speed, and breaking techniques.

Advanced optimization algorithms can increase material utilization by 5-8%. Real-time production monitoring dashboards track performance metrics and identify bottlenecks. Look for connectivity features including remote access for diagnostics and software updates. Open-architecture control systems interface with existing ERP and MES systems for seamless data flow. Advanced machines incorporate machine learning algorithms that continuously optimize cutting parameters based on historical performance data.

Energy Efficiency and Sustainability Features

Energy efficiency features have become important selection criteria. Modern machines use high-efficiency motors with variable frequency drives that consume 20-30% less power than older models. Zoned air management systems activate cushions only where glass is present, reducing air consumption by up to 40%.

Sustainable manufacturing extends to other aspects of machine design. High-precision cutting heads and optimized breaking systems minimize edge trim and rejected pieces. Modern cutting fluids are increasingly biodegradable with extended service life. Some manufacturers offer eco-certification documenting reduced carbon footprint. Modular construction facilitates component replacement rather than complete machine disposal.

Future-Proofing and Adaptability Considerations

The glass industry evolves rapidly with new coating technologies and performance requirements. Modular design allows for targeted upgrades rather than complete replacement when new technologies emerge. Look for expandable software platforms that accommodate new features through updates.

Ensure compatibility with emerging glass technologies, as LOW-E coatings continue to advance with multi-layer systems. Forward-thinking manufacturers design cutting systems with sufficient adjustment range to accommodate both current and anticipated glass technologies. Consider scalability features, such as integration with automated material handling systems. Advanced machines incorporate Industry 4.0 preparation, including standardized communication protocols and comprehensive sensor arrays.

Conclusion

Choosing the best LOW-E glass cutting machine requires careful evaluation of technical specifications, automation capabilities, maintenance requirements, cost considerations, and technological innovations. By assessing these factors against your specific production needs, you can select equipment that provides optimal performance, efficiency, and return on investment. Remember that the right machine will not only meet your current requirements but also adapt to future industry developments, ensuring long-term competitiveness in the evolving glass processing market.

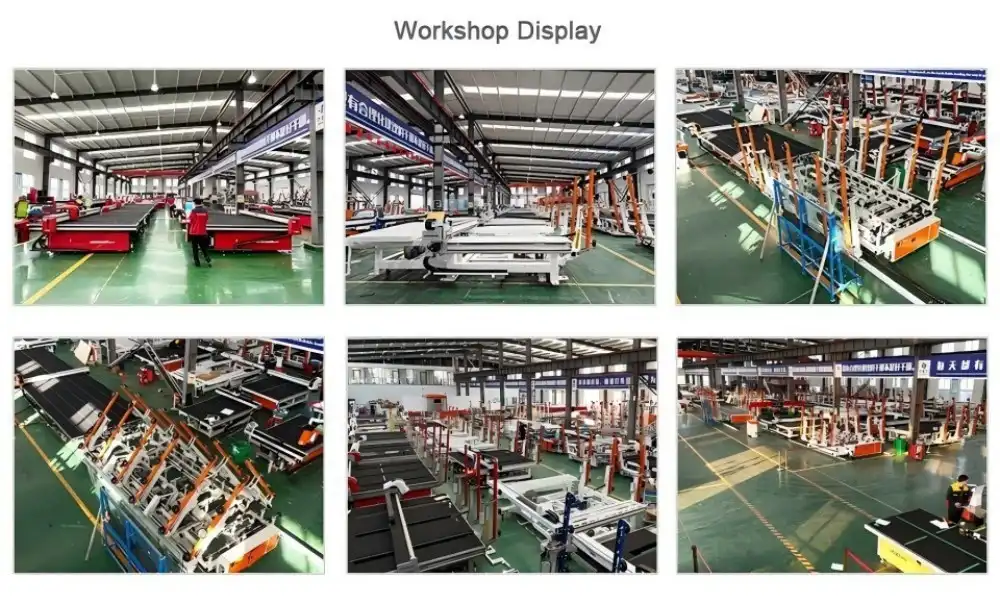

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Anderson, R. & Thompson, K. (2023). "Advances in Automated Glass Cutting Technologies for Energy-Efficient Applications." Journal of Glass Processing Technology, 42(3), 78-92.

2. Chen, H., Williams, J., & Zhang, L. (2024). "Comparative Analysis of LOW-E Glass Processing Equipment: Performance Metrics and Selection Criteria." International Glass Review, 18(2), 145-163.

3. Martínez-Rodríguez, S. & Johnson, P. (2023). "The Economics of Glass Processing Equipment: Cost-Benefit Analysis for Small to Medium Enterprises." Glass Industry Quarterly, 55(1), 29-47.

4. Petrova, N., Smith, J., & Kumar, V. (2024). "Sustainability in Glass Manufacturing: Energy Efficiency Improvements Through Advanced Cutting Technologies." Journal of Sustainable Manufacturing, 16(4), 312-328.

5. Roberts, T. & Wang, Y. (2023). "Industry 4.0 Applications in Glass Processing: Smart Cutting Systems and Digital Integration." Manufacturing Technology Review, 37(2), 183-201.

6. Wilson, D., Li, M., & Patel, S. (2024). "Future Trends in LOW-E Glass Production: Technological Innovations and Market Dynamics." Global Glass Technology Report, 29(1), 56-74.