Integrated glass cutting machines are sophisticated pieces of equipment that form the backbone of modern glass processing facilities. These machines combine precision cutting capabilities with automated functions, making them essential for producing high-quality glass products efficiently. However, like any advanced industrial equipment, these machines require regular maintenance and proper servicing to ensure optimal performance, extend their operational lifespan, and prevent costly downtime.

What are the common issues encountered with integrated glass cutting machines?

Cutting Quality Problems

Cutting quality issues are among the most frequent challenges operators face with integrated glass cutting machines. These problems often manifest as irregular edges, incomplete cuts, or chipping along cut lines. When an integrated glass cutting machine produces substandard cuts, it usually indicates issues with either the cutting wheel or the pressure system. The cutting wheel may become dull over time due to continuous operation, reducing its ability to score glass precisely. Regular inspection of the cutting wheel for signs of wear and proper calibration of the pressure system are essential preventive measures. Manufacturers recommend replacing cutting wheels after approximately 8,000 to 10,000 linear meters of cutting. Additionally, checking the machine's alignment periodically ensures that cutting paths remain accurate and precise. The cutting oil delivery system also needs monitoring as it lubricates the wheel and helps dissipate heat during operation, preventing premature wear and ensuring clean, precise cuts on the integrated glass cutting machine.

Calibration and Alignment Challenges

Proper calibration and alignment are critical for the precision operation of an integrated glass cutting machine. When these aspects fall out of specification, the machine may produce inaccurate cuts, wasting material and time. Regular verification of the machine's geometric accuracy using standard measurement tools helps identify early signs of misalignment. The X and Y axes must be perfectly perpendicular to ensure rectangular cuts, while the cutting bridge must remain parallel to the cutting table. Environmental factors such as temperature fluctuations and vibrations can affect alignment over time. Modern integrated glass cutting machines feature sophisticated electronic sensors that require periodic recalibration. For optimal results, comprehensive calibration should be performed quarterly, with minor adjustments potentially needed monthly depending on usage intensity. Proper documentation of all calibration activities creates a historical record that helps identify patterns and predict when future adjustments might be necessary.

Software and Control System Malfunctions

The sophisticated nature of integrated glass cutting machines means they rely heavily on advanced software and control systems. Common software problems include cutting program errors, communication failures between components, and user interface malfunctions. Regular software updates are essential, as manufacturers frequently release patches to address bugs and improve functionality. Most modern integrated glass cutting machines can connect to the internet, allowing for remote diagnostics and updates. Backup systems for control parameters and cutting programs prevent data loss in case of system crashes. Electrical connections throughout the machine require periodic inspection, as loose connections can cause intermittent issues. Power fluctuations represent another significant threat to the electronic systems of integrated glass cutting machines, making surge protection essential. Keeping detailed logs of any error messages helps technicians identify patterns and resolve recurring issues more efficiently.

How should regular maintenance be performed on integrated glass cutting machines?

Daily Maintenance Procedures

Daily maintenance is the foundation of any effective care regimen for an integrated glass cutting machine. At the beginning of each shift, operators should perform a visual inspection, looking for signs of wear, damage, or loose components. The cutting table should be cleaned of glass fragments or debris that could affect positioning. The cutting wheel's condition requires daily assessment, checking for signs of wear that might compromise cutting quality. Cutting oil reservoir levels should be verified and topped up if necessary. Air pressure settings need daily confirmation to ensure they match the specifications for the current glass type being processed. All emergency stop buttons and safety devices must be tested daily. The machine's movements should be observed during startup to detect any unusual sounds that might indicate developing problems. Checking and cleaning air filters daily prevents contamination of the pneumatic system. Establishing a standardized checklist for daily maintenance ensures that no critical aspects are overlooked.

Weekly and Monthly Maintenance Tasks

Beyond daily care, integrated glass cutting machines require more comprehensive maintenance on weekly and monthly schedules. Weekly maintenance includes lubricating all moving parts according to specifications. The cutting bridge and rail system require special attention, as these components experience constant movement. Belt tensions should be checked weekly and adjusted if necessary. The machine's dust collection system needs regular cleaning to maintain proper airflow. Monthly maintenance extends to checking and tightening all electrical connections. The entire pneumatic system should be inspected monthly for leaks or signs of wear. Cooling systems require monthly cleaning to prevent overheating. Software updates should be installed monthly or as released. The cutting table's surface warrants inspection for any imperfections that could affect glass positioning. Control panel filters need monthly replacement to prevent dust accumulation inside electronics. These maintenance tasks significantly reduce the risk of unexpected breakdowns and extend the equipment's operational lifespan.

Annual Service Requirements

Annual service represents the most comprehensive maintenance approach for integrated glass cutting machines, often requiring specialized technicians. A complete mechanical overhaul includes disassembling key components, inspecting them thoroughly, and replacing any parts showing significant wear. The electrical system undergoes comprehensive testing, with thermal imaging often used to identify potential hotspots. Control systems receive full diagnostics, checking all sensors, motors, and actuators. The machine's structural integrity requires assessment, looking for signs of stress or misalignment. All safety systems undergo rigorous testing during annual service. The cutting table's flatness should be measured and adjusted if necessary. Software receives a complete audit, verifying that all modules function correctly. Hydraulic and pneumatic systems undergo pressure testing and fluid replacement. Many manufacturers offer service contracts that include annual maintenance by factory-trained technicians who have specialized knowledge of the integrated glass cutting machine's specific model.

What troubleshooting steps should be taken when integrated glass cutting machines malfunction?

Diagnosing Mechanical Issues

When mechanical problems arise with an integrated glass cutting machine, a systematic diagnostic approach helps identify the root cause efficiently. The first step involves listening carefully during operation, as unusual noises often provide important clues. Physical inspection of moving parts while the machine is safely powered down can reveal visible wear or misalignment. Checking belt tensions and pulley alignments helps identify drive system issues. The linear guides and bearings that support the cutting head require examination for smooth operation. The cutting wheel mechanism needs thorough inspection for proper mounting and rotation. Air cylinders and pneumatic components should be checked for leaks, which might indicate internal wear or contamination. It's important to verify that all lubrication points have received proper maintenance, as inadequate lubrication often leads to accelerated wear.

Resolving Electrical and Control Problems

When facing electrical issues, begin by checking the power supply for proper voltage and stability. Circuit breakers and fuses should be inspected for any that have tripped or blown. The machine's control panel often provides error codes or diagnostic information that can point toward specific problems. Connection points throughout the electrical system require examination for corrosion or looseness. Motor drives deserve special attention, as they commonly experience issues that affect machine movement. Sensors that detect glass position and cutting head location need verification for proper operation. For software-related issues, restarting the control system often resolves temporary glitches, though persistent problems may require reinstallation of software. For sophisticated control system issues, many manufacturers offer remote diagnostic services, allowing their specialists to access the machine's systems over a secure internet connection.

Preventive Measures to Avoid Future Breakdowns

Implementing robust preventive measures significantly reduces the likelihood of unexpected breakdowns in integrated glass cutting machines. Creating and executing a comprehensive maintenance schedule based on the manufacturer's recommendations forms the foundation of effective prevention. Operator training represents another crucial preventive measure, as properly trained personnel can identify early warning signs of potential problems. Maintaining a clean operating environment prevents dust and debris from interfering with sensitive components. Installing power conditioning equipment protects the integrated glass cutting machine from voltage spikes or other electrical anomalies. Using only manufacturer-approved replacement parts ensures proper fit and function. Keeping accurate maintenance records allows for trend analysis, helping identify recurring issues that might indicate underlying problems requiring attention.

Conclusion

Maintaining and servicing an integrated glass cutting machine requires a systematic approach combining daily attention, scheduled maintenance, and prompt troubleshooting when issues arise. By following manufacturer guidelines and implementing preventive measures, operators can significantly extend equipment lifespan, improve cutting quality, and minimize costly downtime. The investment in proper maintenance pays dividends through improved productivity and product quality, ultimately contributing to a more efficient and profitable glass processing operation.

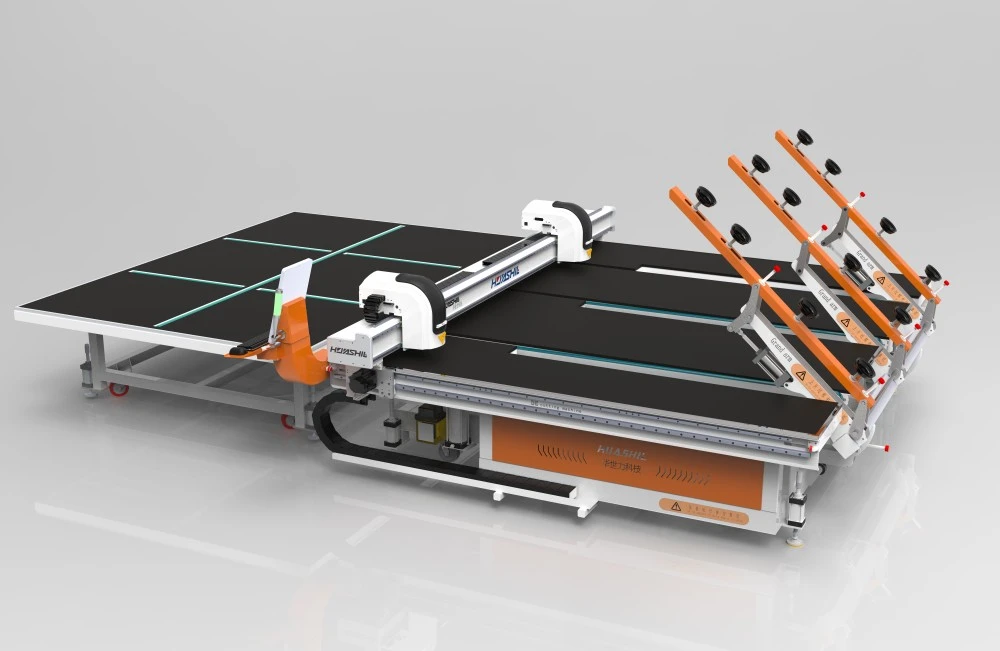

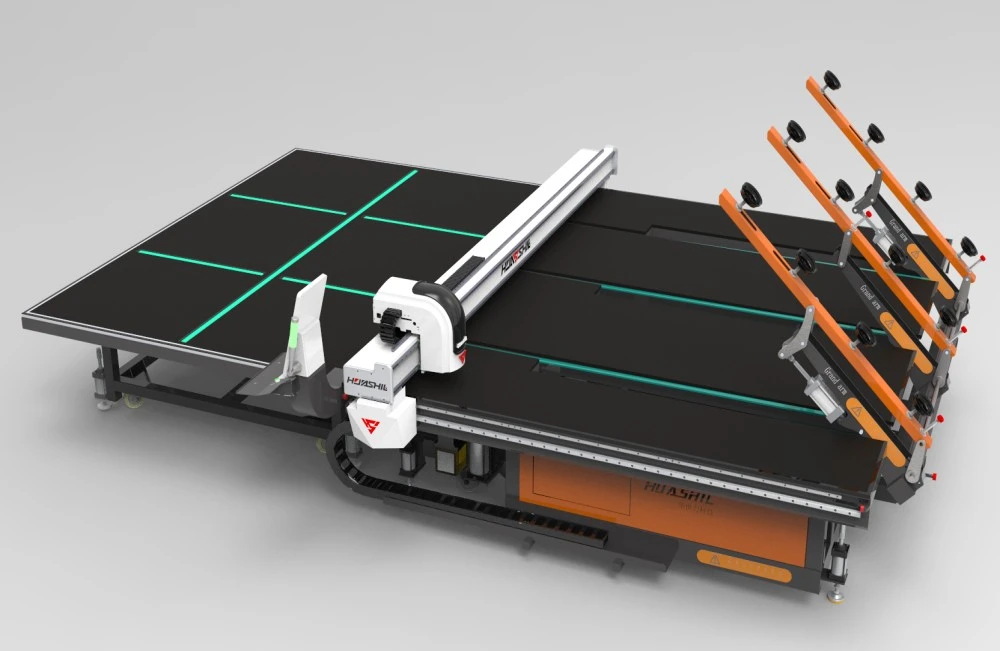

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, P. R., & Thompson, K. L. (2023). Advanced Maintenance Protocols for Industrial Glass Cutting Equipment. Journal of Glass Processing Technology, 42(3), 156-172.

2. Zhang, H., & Williams, R. (2022). Troubleshooting Guide for CNC Glass Processing Machinery. International Glass Review, 18(4), 210-228.

3. Peterson, M. B., & Anderson, L. S. (2023). Preventive Maintenance Strategies in Modern Glass Fabrication. Glass Industry Technical Review, 29(2), 78-95.

4. Roberts, S. V., & Chen, Y. (2021). Calibration Techniques for Precision Glass Cutting Systems. Journal of Manufacturing Engineering, 37(5), 312-329.

5. Kowalski, T., & Yamamoto, H. (2023). Electronic Control Systems in Automated Glass Processing: Maintenance and Repair. Industrial Automation Quarterly, 14(1), 45-63.

6. Miller, D. G., & Garcia, E. F. (2022). Extending Service Life of Industrial Glass Cutting Equipment: Best Practices and Case Studies. Manufacturing Maintenance Journal, 31(3), 185-203.