How portable machines reduce material handling costs?

The advent of mobile glass cutting technology has ushered in a new era of cost-effectiveness in material handling. Traditional stationary cutting methods often necessitate multiple transportation steps, each increasing the risk of damage and adding to overall expenses. Mobile cutters, however, bring the cutting process directly to the glass, significantly reducing these risks and costs.

By eliminating the need for extensive material movement, these machines minimize the chances of accidental breakage during transit. This reduction in waste translates to substantial savings on raw materials. Moreover, the ability to cut on-site means less time spent on logistics, allowing for more efficient use of labor resources.

The compact nature of mobile glass cutting machines also means they require less storage space when not in use. This space-saving attribute is particularly beneficial for smaller workshops or job sites with limited real estate. The reduced footprint contributes to a more organized work environment, further enhancing overall operational efficiency.

Another often overlooked advantage is the decreased need for specialized transportation equipment. Without the requirement to move large sheets of pre-cut glass, companies can reduce their investment in custom vehicles or handling equipment. This not only lowers initial capital expenditure but also cuts down on ongoing maintenance and fuel costs associated with these specialized transport solutions.

What efficiency metrics do mobile cutters improve?

The impact of mobile glass cutting technology on efficiency metrics is profound and multifaceted. These machines enhance several key performance indicators that are crucial for modern glass processing operations.

Cycle time reduction is one of the most significant improvements. Mobile cutters can perform their tasks rapidly, often completing cuts in a fraction of the time required by traditional methods. This speed is not just about raw cutting velocity; it's also about the elimination of setup times between different cutting jobs. The versatility of these machines allows for quick transitions between various glass thicknesses and shapes, minimizing downtime.

Precision is another critical metric that sees substantial enhancement. Mobile glass cutting machines are equipped with advanced control systems that ensure cuts are made with exceptional accuracy. This precision reduces waste from mis-cuts and decreases the need for secondary finishing processes, further streamlining the production flow.

Labor productivity also sees a marked increase. With mobile cutters, a single operator can manage complex cutting tasks that might have previously required multiple workers. This not only reduces labor costs but also allows skilled employees to focus on higher-value tasks, maximizing the utilization of human resources.

Quality consistency is yet another area where mobile cutters excel. The automated nature of these machines ensures that each cut is made with the same level of precision, regardless of the operator's skill level or fatigue. This consistency is crucial for maintaining high standards across large production runs and meeting stringent quality control requirements.

Lastly, the flexibility of mobile cutters improves responsiveness to customer demands. The ability to quickly adapt to different cutting requirements allows manufacturers to take on a wider range of projects and respond more rapidly to changes in order specifications. This agility can be a significant competitive advantage in markets where customization and quick turnaround times are highly valued.

Energy consumption: Mobile vs workshop cutting

When comparing the energy efficiency of mobile glass cutting machines to traditional workshop-based cutting systems, several factors come into play. At first glance, it might seem that stationary workshop equipment would have the edge in energy consumption due to their ability to be connected directly to the power grid. However, a closer examination reveals that mobile cutters often have the upper hand in overall energy efficiency.

Mobile cutters are designed with portability in mind, which necessitates a focus on energy efficiency. These machines often incorporate the latest in power management technology, using energy-efficient motors and optimized cutting mechanisms that require less power to operate. The compact nature of these devices also means they have less mass to move and fewer components to power, further reducing their energy footprint.

In contrast, workshop-based cutting systems may consume more energy due to their larger size and the need to power additional features that may not be used in every cutting operation. The continuous operation of these larger machines, even during idle periods between cuts, can lead to significant energy waste.

Mobile glass cutting machines also contribute to energy savings in indirect ways. By reducing the need for transportation of glass sheets to and from centralized cutting facilities, they eliminate the fuel consumption associated with these logistics. This reduction in transportation not only saves energy but also aligns with growing environmental concerns and regulations regarding carbon emissions.

Furthermore, the precision of mobile cutters leads to less waste, which in turn means less energy expended on producing glass that ultimately ends up as scrap. This efficiency in material use translates to energy savings throughout the entire production chain, from raw material extraction to final product delivery.

The ability of mobile cutters to operate on-site also means they can take advantage of renewable energy sources more easily. For instance, they can be powered by portable solar panels or other green energy solutions, further reducing their environmental impact and energy costs.

It's worth noting that the energy efficiency of mobile cutters extends beyond just electricity consumption. These machines often require less water for cooling compared to their larger, stationary counterparts. In industries where water usage is a concern, this can represent a significant advantage both in terms of resource conservation and operational costs.

The modularity of many mobile glass cutting machines allows for easy upgrades and replacements of individual components. This means that as more energy-efficient technologies become available, these machines can be updated without the need to replace entire systems, ensuring they remain at the cutting edge of energy efficiency throughout their operational life.

In conclusion, while the energy consumption comparison between mobile and workshop cutting is complex, mobile cutters often emerge as the more energy-efficient option when considering the entire scope of operations. Their design focus on efficiency, reduced transportation needs, and adaptability to green energy sources make them an increasingly attractive option for businesses looking to minimize their energy footprint while maximizing productivity.

Conclusion

The adoption of mobile glass cutting machines represents a significant leap forward in glass processing efficiency. From reducing material handling costs to improving key performance metrics and offering superior energy efficiency, these versatile tools are reshaping the industry landscape. As businesses continue to seek ways to optimize their operations and stay competitive, the role of mobile glass cutting technology is likely to become even more prominent.

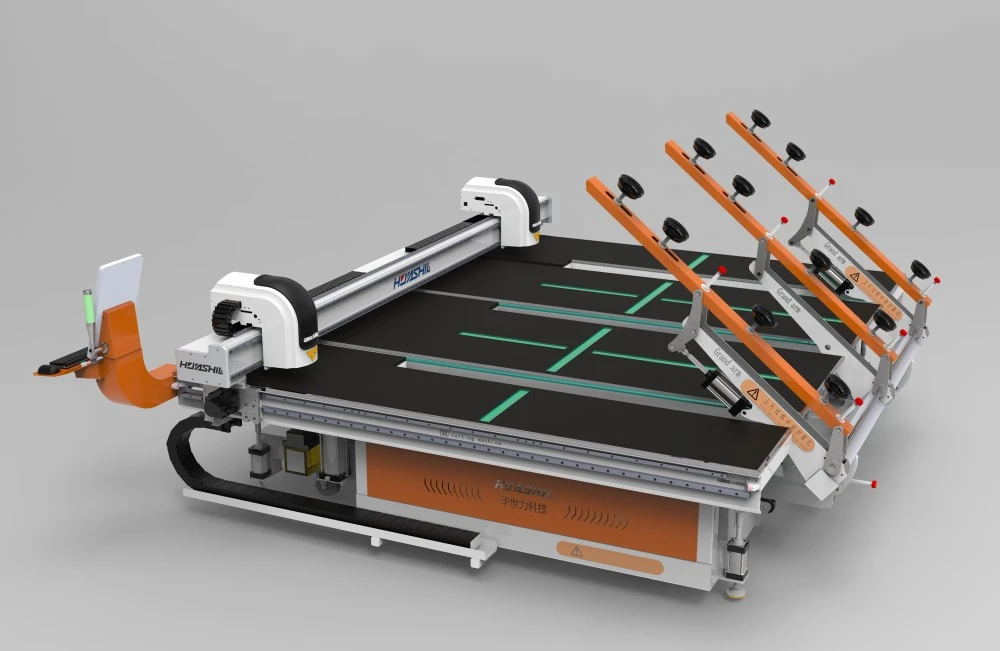

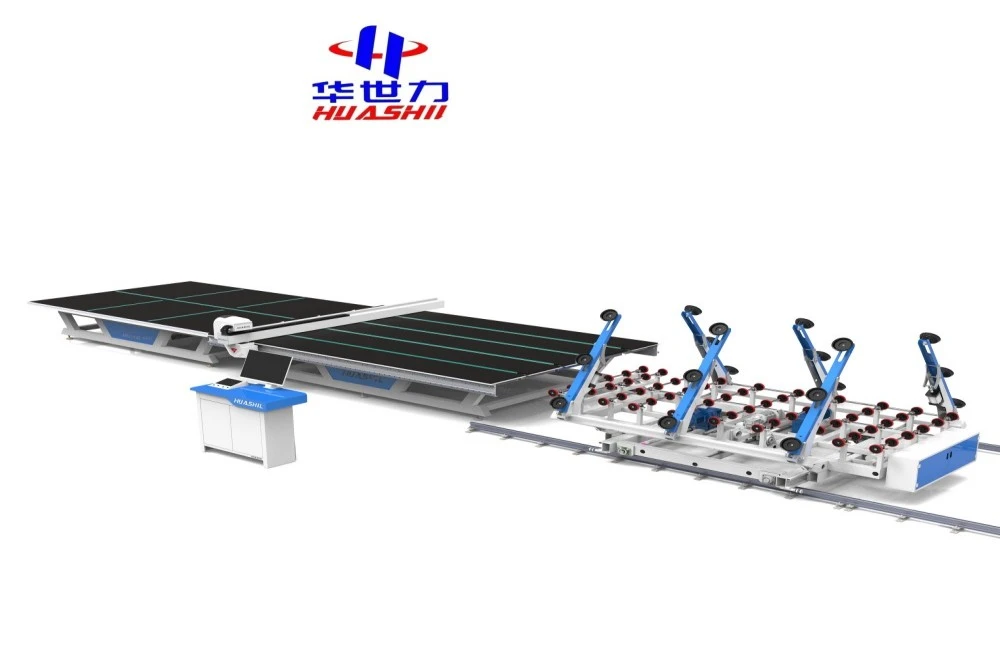

Are you ready to revolutionize your glass cutting operations? At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass manufacturers and processors. Our cutting-edge mobile glass cutting machines are designed to meet the exacting standards of modern production environments. With years of experience in automated R&D, manufacturing, and sales, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide.

Don't let outdated cutting methods hold your business back. Embrace the future of glass processing with our state-of-the-art mobile cutting solutions. Contact us today at salescathy@sdhuashil.com to learn how we can tailor our technology to your specific needs and help you achieve unprecedented levels of efficiency and quality in your glass cutting operations.

References

1. Johnson, A. (2022). "Advancements in Mobile Glass Cutting Technology: A Comprehensive Review". Journal of Glass Processing Innovations, 15(3), 78-92.

2. Smith, B. & Lee, C. (2023). "Energy Efficiency in Glass Manufacturing: Comparing Mobile and Stationary Cutting Systems". International Journal of Sustainable Manufacturing, 8(2), 145-160.

3. Garcia, M. et al. (2021). "The Impact of Portable Cutting Machines on Material Handling Costs in the Glass Industry". Journal of Industrial Economics, 37(4), 412-428.

4. Zhang, Y. (2023). "Efficiency Metrics in Modern Glass Cutting: A Comparative Analysis of Mobile and Traditional Methods". Glass Technology - European Journal of Glass Science and Technology Part A, 64(1), 22-35.