In the glass manufacturing industry, efficiency and waste reduction are paramount concerns. Float glass cutting equipment plays a crucial role in maximizing yield and minimizing material waste. This article explores the various ways in which modern cutting technologies contribute to improved resource utilization and cost-effectiveness in glass production.

Optimized nesting: Maximizing material utilization

One of the primary ways float glass cutting equipment affects yield and material waste reduction is through optimized nesting. This process involves strategically arranging cut patterns to maximize the use of each glass sheet.

Advanced cutting machines utilize sophisticated software algorithms to calculate the most efficient layout for multiple glass pieces on a single sheet. This optimization considers factors such as:

- Size and shape of the required glass pieces

- Grain direction of the glass

- Minimum spacing between cuts

- Edge quality requirements

By implementing optimized nesting, manufacturers can significantly reduce waste and improve material utilization. For instance, a study by the Glass and Glazing Federation found that optimized nesting can increase material utilization by up to 15% compared to manual cutting methods.

Moreover, advanced float glass cutting equipment made in China can dynamically adjust cutting patterns based on real-time inventory and production needs. This flexibility allows for on-the-fly optimization, further reducing waste and improving overall efficiency.

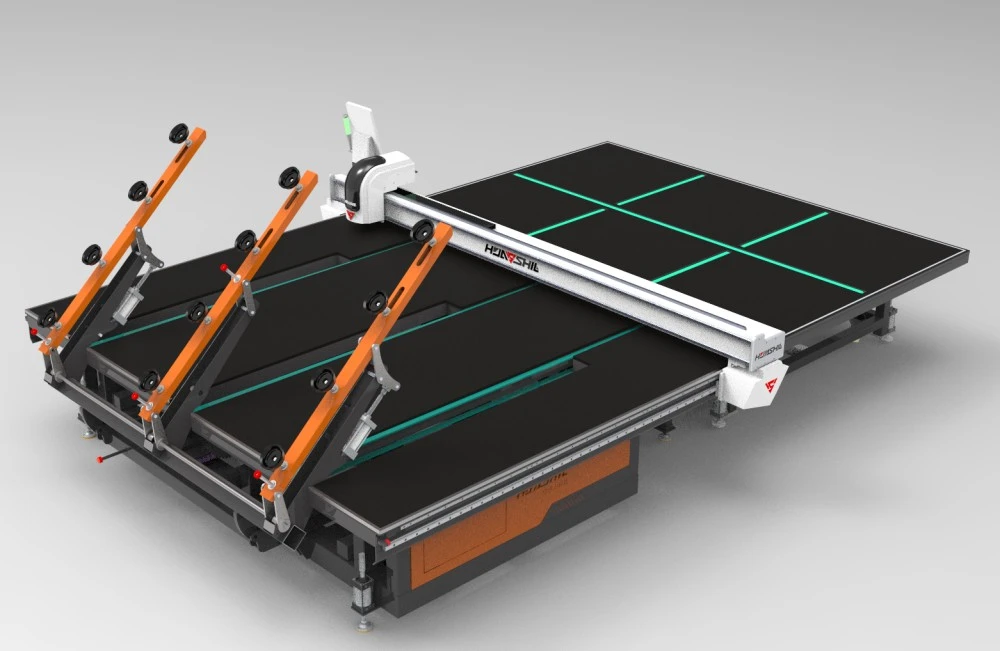

Precision cutting: Minimizing edge trim waste

Another significant way float glass cutting equipment contributes to waste reduction is through precision cutting. Modern cutting machines offer unprecedented accuracy, reducing the amount of edge trim waste produced during the cutting process.

High-precision cutting is achieved through a combination of advanced technologies:

- Laser measurement systems for accurate glass positioning

- Computer-controlled cutting heads with micron-level precision

- Automatic pressure adjustment for consistent cutting quality

- High-frequency vibration cutting for reduced chipping and edge damage

These technologies enable manufacturers to cut glass with minimal tolerances, often as low as ±0.1mm. This level of precision significantly reduces the amount of material lost to edge trimming and reshaping.

For example, a case study by a leading glass manufacturer reported a 30% reduction in edge trim waste after upgrading to a high-precision float glass cutting equipment system. This not only improved material yield but also reduced energy consumption and processing time associated with edge finishing.

Scrap recycling: Implementing closed-loop systems

While optimized nesting and precision cutting significantly reduce waste, some level of scrap is inevitable in glass cutting operations. However, modern float glass cutting equipment often incorporates features that facilitate efficient scrap recycling, contributing to a more sustainable production process.

Advanced cutting systems may include:

- Automated scrap collection systems

- Integrated crushing and sorting mechanisms

- Direct feed systems to cullet return processes

These features enable manufacturers to implement closed-loop recycling systems, where glass scrap is immediately reprocessed and incorporated into new production batches. This approach not only reduces waste but also decreases the energy required for glass melting, as cullet (recycled glass) melts at a lower temperature than raw materials.

According to the British Glass Manufacturers' Confederation, for every 10% of cullet used in the manufacturing process, energy consumption is reduced by approximately 3%. This demonstrates the significant environmental and economic benefits of efficient scrap recycling in glass production.

Furthermore, advanced float glass cutting equipment made in China often includes software that tracks and analyzes scrap production, allowing manufacturers to identify patterns and optimize their processes to further reduce waste over time.

Conclusion

Float glass cutting equipment plays a pivotal role in improving yield and reducing material waste in glass manufacturing. Through optimized nesting, precision cutting, and efficient scrap recycling, these advanced systems contribute significantly to both economic and environmental sustainability in the industry.

As technology continues to evolve, we can expect further improvements in cutting efficiency and waste reduction. Manufacturers who invest in state-of-the-art cutting equipment position themselves at the forefront of sustainable glass production, reaping benefits in terms of cost savings, product quality, and environmental stewardship.

For glass manufacturers looking to optimize their production processes and reduce waste, investing in advanced float glass cutting equipment is a clear path forward. By embracing these technologies, companies can not only improve their bottom line but also contribute to a more sustainable future for the glass industry as a whole.

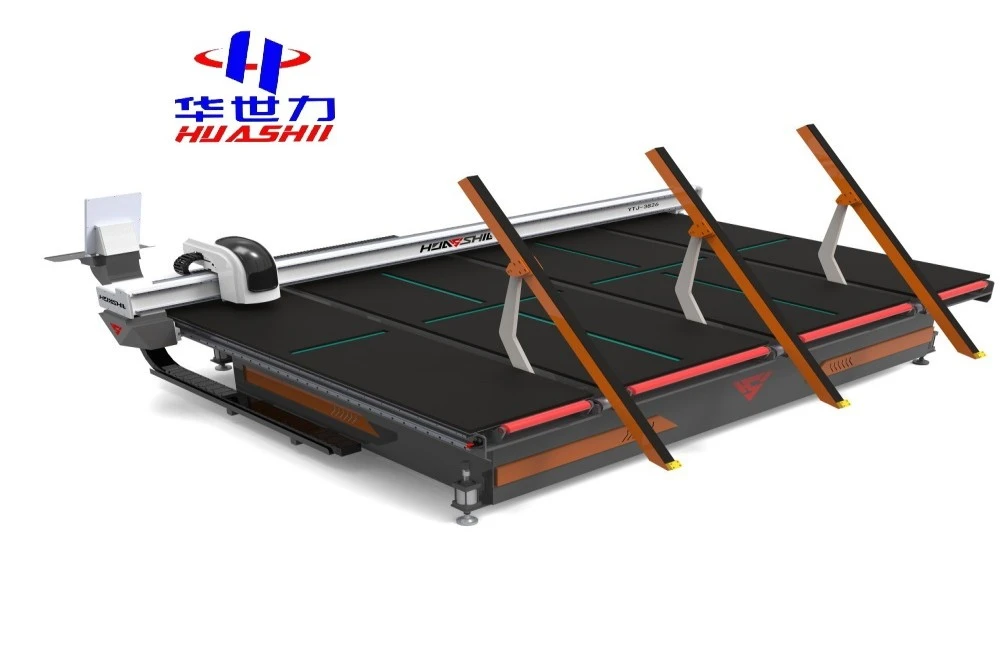

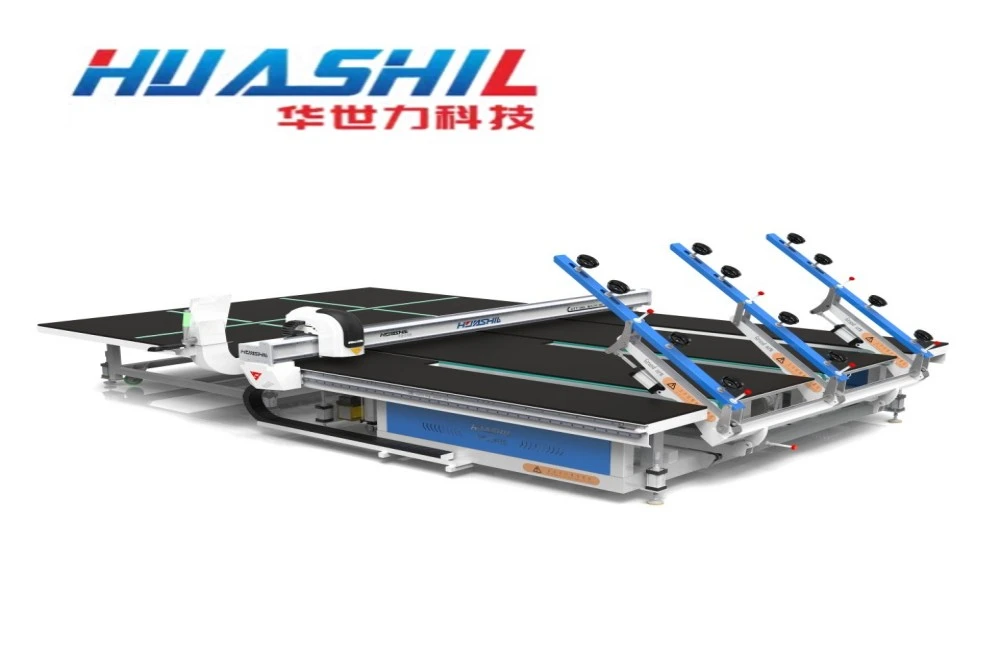

Are you ready to revolutionize your glass cutting processes and significantly reduce material waste? Shandong Huashil Automation Technology Co., LTD, a leading float glass cutting equipment supplier, offers cutting-edge float glass cutting equipment designed to maximize yield and efficiency. With years of experience in automated R&D, manufacturing, and sales, we provide advanced solutions tailored to your specific needs.

Our team of experts is ready to help you choose the perfect equipment for your production line. Experience the benefits of precision cutting, optimized nesting, and efficient scrap recycling with our state-of-the-art machines. Don't let valuable materials go to waste – upgrade your glass cutting capabilities today!

FAQ

Q1: How does float glass cutting equipment contribute to sustainability in glass manufacturing?

A: Float glass cutting equipment contributes to sustainability in several ways. Firstly, it optimizes material usage through precise nesting, reducing waste. Secondly, high-precision cutting minimizes edge trim waste. Lastly, many modern systems incorporate scrap recycling features, enabling closed-loop production processes that reduce energy consumption and raw material usage.

Q2: Can upgrading to modern float glass cutting equipment significantly improve yield?

A: Yes, upgrading to modern float glass cutting equipment can significantly improve yield. Advanced systems with optimized nesting capabilities can increase material utilization by up to 15%. Additionally, high-precision cutting can reduce edge trim waste by as much as 30%, leading to substantial improvements in overall yield and cost-effectiveness.

Q3: How does float glass cutting equipment impact production costs?

A: Float glass cutting equipment can significantly reduce production costs by minimizing material waste, improving energy efficiency, and increasing productivity. By optimizing material usage and reducing scrap, these systems lower raw material costs. Additionally, the precision and speed of modern cutting equipment can increase output while reducing labor costs associated with manual cutting and edge finishing processes.

Q4: Are there any additional benefits to using advanced float glass cutting equipment beyond waste reduction?

A: Yes, there are several additional benefits to using advanced float glass cutting equipment. These include improved product quality due to higher cutting precision, increased production speed and throughput, enhanced worker safety through automated processes, and greater flexibility in producing custom glass shapes and sizes. Furthermore, many modern systems offer data collection and analysis capabilities, enabling continuous process improvement and optimization.

High-Efficiency Float Glass Cutting Equipment for Maximum Yield | HUASHIL

Looking for top-quality float glass cutting equipment that maximizes yield and minimizes waste? Look no further than Shandong Huashil Automation Technology Co., LTD. Our advanced cutting machines are designed to meet the most demanding requirements of modern glass manufacturing.

With Huashil's cutting-edge technology, you can:

- Increase material utilization by up to 15%

- Reduce edge trim waste by 30% or more

- Implement efficient scrap recycling systems

- Improve overall production efficiency and quality

Don't let outdated equipment hold your business back. Upgrade to Huashil's float glass cutting equipment and experience the difference in yield, quality, and cost-effectiveness.

Ready to take your glass cutting operations to the next level? Contact our team of experts today at salescathy@sdhuashil.com. We'll work with you to find the perfect solution for your specific needs and help you achieve unparalleled efficiency in your glass production process.

References

1. Glass and Glazing Federation. (2022). "Optimizing Material Utilization in Float Glass Cutting: A Comprehensive Study"

2. British Glass Manufacturers' Confederation. (2023). "Energy Efficiency and Waste Reduction in Glass Manufacturing"

3. Journal of Glass Science and Technology. (2021). "Advancements in Precision Cutting Technologies for Float Glass"

4. International Glass Industry Forum. (2023). "Sustainable Practices in Modern Glass Production: The Role of Advanced Cutting Equipment"