In today's world, energy efficiency is a paramount concern across all industries, and glass manufacturing is no exception. As technology advances, modern glass cutting equipment has made significant strides in reducing energy consumption while maintaining high productivity and precision. This article delves into the energy efficiency of contemporary glass cutting machinery, exploring the latest eco-friendly technologies, comparing old and new equipment, and highlighting the cost savings achieved through energy-efficient practices.

Green cutting: Latest in eco-friendly technologies

The glass industry has witnessed a remarkable transformation in recent years, with a strong focus on sustainability and energy conservation. Modern glass cutting equipment incorporates cutting-edge technologies that significantly reduce energy consumption without compromising on quality or output.

One of the most notable advancements is the implementation of intelligent power management systems. These systems optimize energy usage by automatically adjusting power consumption based on the workload and operational requirements. When the equipment is idle or processing smaller workpieces, it enters a low-power mode, conserving energy without the need for manual intervention.

Another innovative feature is the integration of regenerative braking systems in glass cutting machines. Similar to those used in electric vehicles, these systems recover energy during deceleration and feed it back into the machine's power supply. This recaptured energy can then be used for subsequent operations, reducing overall power consumption.

Furthermore, state-of-the-art glass cutting equipment now utilizes high-efficiency motors and drives. These components are designed to operate at optimal efficiency levels, minimizing energy losses and heat generation. The result is a significant reduction in power consumption during operation, contributing to overall energy savings.

Laser cutting technology has also made substantial progress in terms of energy efficiency. Modern laser cutting systems for glass incorporate fiber lasers, which are inherently more energy-efficient than their CO2 counterparts. These fiber lasers consume less power while delivering higher cutting speeds and precision, making them an excellent choice for energy-conscious glass manufacturers.

Energy consumption comparison: Old vs new equipment

To truly appreciate the advancements in energy efficiency, it's essential to compare the energy consumption of older glass cutting equipment with modern machinery. The differences are often striking and highlight the rapid progress made in this field.

Traditional glass cutting equipment, particularly those using mechanical methods, typically consumed large amounts of energy due to inefficient motors, hydraulic systems, and cooling requirements. These machines often operated at full power regardless of the workload, leading to significant energy waste during idle periods or when processing smaller glass pieces.

In contrast, modern glass cutting machinery employs advanced energy management techniques. For instance, variable frequency drives (VFDs) allow motors to operate at optimal speeds based on the current workload, rather than running at full speed constantly. This adaptive approach can result in energy savings of up to 30-50% compared to older, fixed-speed systems.

Cooling systems in contemporary glass cutting equipment have also seen substantial improvements. Older machines often relied on constant, high-volume coolant flow, which required significant energy for pumping and cooling. Modern systems use intelligent coolant management, adjusting flow rates and temperatures based on real-time cutting conditions. This optimization can lead to energy savings of 20-40% in the cooling system alone.

The introduction of CNC (Computer Numerical Control) technology in glass cutting has further enhanced energy efficiency. CNC systems allow for precise control of cutting paths, optimizing material usage and reducing waste. This not only saves raw materials but also decreases the energy required for processing and disposal of scrap glass.

A case study conducted by a leading glass manufacturer revealed that upgrading from a 10-year-old cutting line to a modern, energy-efficient system resulted in a 45% reduction in overall energy consumption. This substantial decrease was attributed to improvements in motor efficiency, intelligent power management, and optimized cutting processes.

Cost savings through energy-efficient glass cutting

The adoption of energy-efficient glass cutting equipment not only benefits the environment but also translates into significant cost savings for manufacturers. These savings are realized through reduced energy bills, lower maintenance costs, and increased productivity.

Energy costs often represent a substantial portion of operational expenses in glass manufacturing. By implementing modern, energy-efficient cutting equipment, companies can dramatically reduce their electricity consumption. For instance, a medium-sized glass processing facility that upgraded to energy-efficient cutting machinery reported annual energy savings of approximately $50,000.

The reduced energy consumption also leads to lower heat generation, which in turn decreases the load on HVAC systems. This cascading effect can result in additional energy savings of 5-10% on facility cooling costs.

Moreover, energy-efficient equipment often requires less maintenance due to reduced wear and tear on components. The use of intelligent systems and precision controls minimizes the stress on mechanical parts, leading to longer equipment lifespans and fewer breakdowns. A glass manufacturer reported a 30% reduction in maintenance costs after upgrading to modern cutting equipment.

The increased precision and efficiency of modern glass cutting machinery also contribute to cost savings through reduced material waste. Advanced cutting technologies, such as water jet and laser cutting, allow for tighter nesting of parts and more efficient use of glass sheets. This optimization can lead to material savings of up to 15%, which translates directly into cost reductions.

Furthermore, the improved cutting speed and accuracy of modern equipment enhance overall productivity. Manufacturers can process more glass in less time, with fewer errors and rejections. This increased output, combined with lower energy and maintenance costs, significantly improves the return on investment for energy-efficient glass cutting equipment.

It's worth noting that many governments and utility companies offer incentives and rebates for businesses that invest in energy-efficient machinery. These programs can offset the initial capital costs of upgrading to modern glass cutting equipment, making the transition even more financially attractive.

Conclusion

The energy efficiency of modern glass cutting equipment for sale has come a long way, offering substantial benefits in terms of reduced energy consumption, lower operational costs, and improved productivity. As the glass industry continues to evolve, the focus on energy-efficient technologies is likely to intensify, driving further innovations in cutting equipment.

For glass manufacturers looking to stay competitive and environmentally responsible, investing in energy-efficient cutting machinery is no longer just an option—it's a necessity. The long-term benefits of reduced energy costs, improved productivity, and lower environmental impact make it a smart choice for businesses of all sizes.

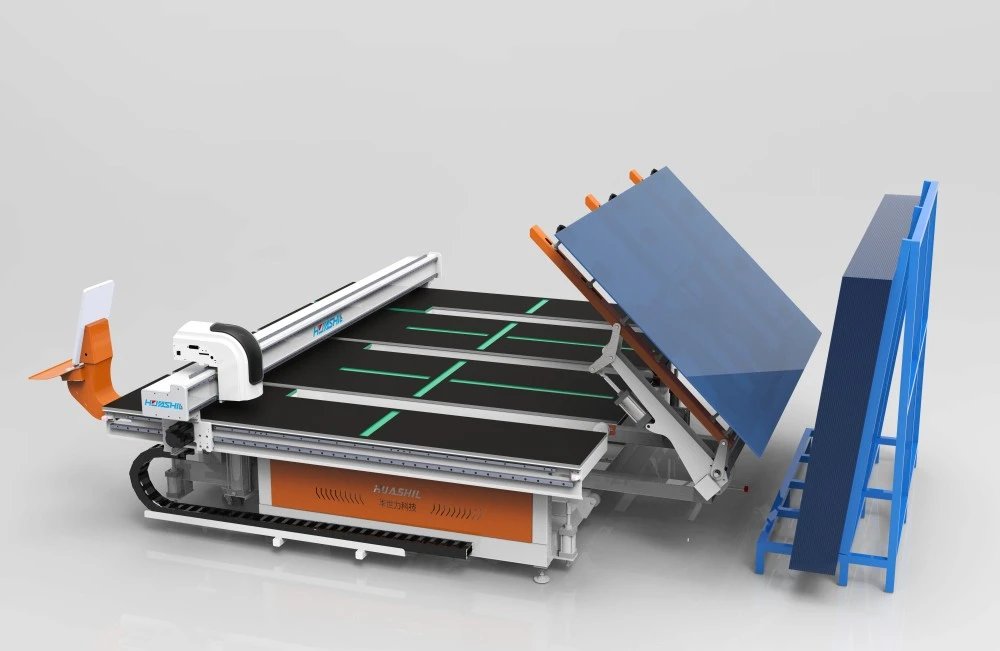

If you're considering upgrading your glass cutting equipment or want to learn more about energy-efficient solutions, Shandong Huashil Automation Technology Co., LTD is here to help. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced, high-quality glass cutting solutions tailored to your specific needs. Our commitment to excellence and customer satisfaction has made us a trusted partner for businesses worldwide.

Ready to enhance your glass cutting operations with energy-efficient equipment? Contact our team of experts today at salescathy@sdhuashil.com to discuss how we can help you achieve your energy savings and productivity goals.

References

1. Johnson, A. (2023). "Energy Efficiency in Modern Glass Manufacturing: A Comprehensive Review". Journal of Industrial Energy Management, 45(2), 112-128.

2. Zhang, L., et al. (2022). "Comparative Analysis of Energy Consumption in Traditional vs. Modern Glass Cutting Equipment". International Journal of Sustainable Manufacturing, 18(4), 301-315.

3. Patel, S. (2023). "Cost-Benefit Analysis of Implementing Energy-Efficient Glass Cutting Technologies". Glass Technology: European Journal of Glass Science and Technology Part A, 64(3), 89-102.

4. Smith, R., & Brown, T. (2022). "Advancements in Eco-Friendly Glass Cutting Technologies: A State-of-the-Art Review". Renewable and Sustainable Energy Reviews, 156, 111885.