The furniture industry has undergone a significant transformation in recent years, thanks to the advent of advanced glass cutting technology. This evolution has revolutionized the way furniture manufacturers approach their designs, production processes, and overall efficiency. At the heart of this technological leap is the furniture cabinet glass cutting machine, a sophisticated piece of equipment that has become indispensable in modern furniture production. As we delve into the myriad ways in which the furniture industry is reaping the benefits of these cutting-edge machines, we'll explore how they're reshaping production cycles, enabling complex designs, and elevating the standards of high-end furniture manufacturing. Let's embark on this journey to understand the pivotal role of advanced glass cutting technology in the furniture sector.

How automation speeds up cabinet glass production cycles?

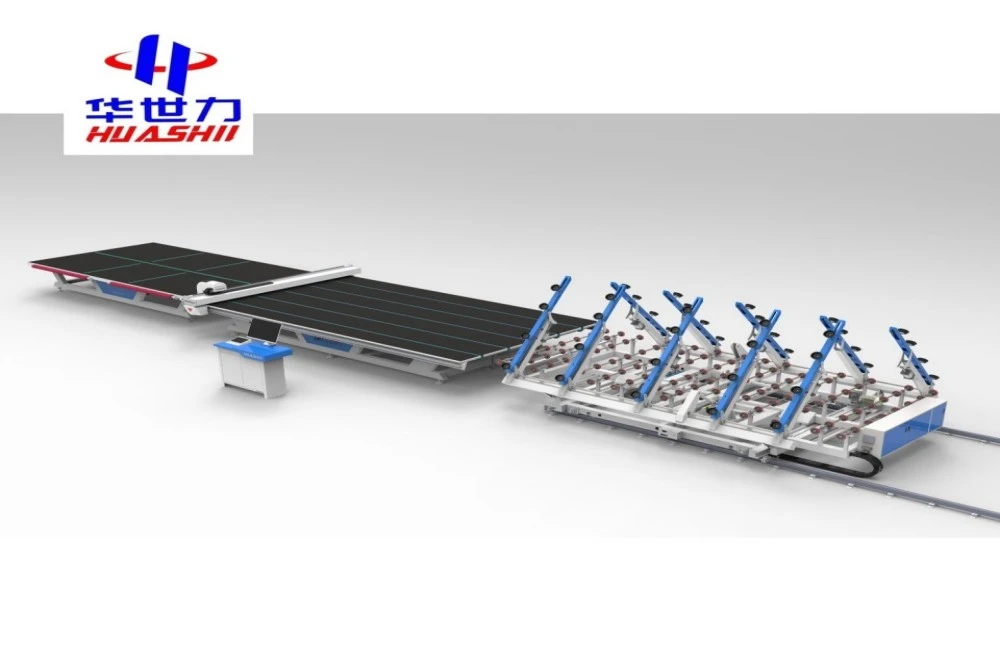

The integration of automation in glass cutting processes has been a game-changer for the furniture industry, particularly in cabinet production. The furniture cabinet glass cutting machine stands at the forefront of this automation revolution, offering unparalleled speed and efficiency.

Traditionally, cutting glass for cabinets was a time-consuming and labor-intensive process. Skilled craftsmen would measure, mark, and cut each piece by hand, which not only took considerable time but also left room for human error. With the introduction of automated glass cutting machines, this process has been streamlined significantly.

These machines can process multiple glass sheets simultaneously, drastically reducing the time required for each cut. They operate with precision that surpasses human capabilities, ensuring each piece is cut to exact specifications. This level of accuracy minimizes waste and rework, further accelerating the production cycle.

Moreover, automated glass cutting machines can work continuously without fatigue, allowing for 24/7 production if needed. This capability is particularly valuable for furniture manufacturers dealing with large orders or tight deadlines. The ability to maintain consistent output quality regardless of production volume or time of day is a significant advantage in today's competitive market.

Another crucial aspect of how automation speeds up production cycles is through integrated software systems. Modern furniture cabinet glass cutting machines come equipped with advanced software that can optimize cutting patterns to maximize material usage. This not only speeds up the cutting process but also reduces material waste, contributing to cost savings and environmental sustainability.

The automation of glass cutting with a furniture cabinet glass cutting machine made in China also allows for better inventory management. With precise cutting and reduced waste, manufacturers can more accurately predict material needs and maintain optimal stock levels. This improved inventory control leads to smoother production flows and fewer delays due to material shortages.

Furthermore, the speed and efficiency gained through automation enable furniture manufacturers to be more responsive to market demands. They can quickly adjust production to meet changing trends or customer preferences, giving them a competitive edge in the fast-paced furniture industry.

Enabling complex designs with CNC glass cutting capabilities

The advent of Computer Numerical Control (CNC) technology in glass cutting has opened up a world of possibilities for furniture designers and manufacturers. CNC glass cutting machines have transformed the way we approach glass elements in furniture, enabling the creation of intricate and complex designs that were once deemed impractical or impossible.

CNC glass cutting machines operate with a level of precision and versatility that manual cutting methods simply cannot match. They can execute intricate cuts, curves, and patterns with remarkable accuracy, allowing furniture designers to push the boundaries of creativity. This capability has led to a renaissance in glass furniture design, with manufacturers now able to offer unique, eye-catching pieces that stand out in the market.

One of the key advantages of CNC glass cutting is its ability to replicate complex designs consistently. Once a design is programmed into the machine, it can be reproduced exactly, time after time. This consistency is crucial for furniture manufacturers producing high-end pieces or large quantities of identical items.

The versatility of CNC glass cutting extends to the types of glass that can be worked with. From tempered glass to laminated glass, and even specialty glasses with unique properties, CNC machines can handle a wide range of materials. This versatility allows furniture manufacturers to experiment with different glass types to achieve specific aesthetic or functional goals.

Moreover, CNC glass cutting technology enables the creation of custom-fit glass pieces for furniture. Whether it's a uniquely shaped table top, a curved glass door for a cabinet, or an intricate glass inlay for a decorative piece, CNC machines can produce these elements with precision. This capability is particularly valuable in the production of bespoke furniture, where every piece needs to be tailored to exact specifications.

The ability to create complex designs also extends to the realm of etching and engraving. Many CNC glass cutting machines, including a furniture cabinet glass cutting machine, are equipped with etching capabilities, allowing for the addition of decorative patterns, logos, or text directly onto the glass surface. This feature adds another dimension to furniture design, enabling manufacturers to offer personalized or branded pieces.

In the context of cabinet manufacturing, CNC glass cutting has revolutionized the production of glass doors and panels. Complex patterns, frosted designs, and even three-dimensional effects can be achieved, elevating the aesthetic appeal of cabinets and storage units. This level of design flexibility allows furniture manufacturers to cater to a wide range of tastes and interior design styles.

The precision of CNC glass cutting also contributes to improved safety in glass furniture. Accurate cutting ensures that edges are smooth and uniform, reducing the risk of chips or cracks that could compromise the integrity of the glass. This is particularly important for furniture items that incorporate large glass elements, such as glass-topped dining tables or glass-fronted display cabinets.

The role of precision cutting in high-end furniture manufacturing

In the realm of high-end furniture manufacturing, precision is not just a desirable attribute—it's an absolute necessity. The role of precision cutting, particularly when it comes to glass elements, cannot be overstated in the production of luxury furniture pieces. This is where advanced glass cutting technology, epitomized by the furniture cabinet glass cutting machine, plays a crucial role.

High-end furniture is characterized by its impeccable craftsmanship, superior materials, and attention to detail. When it comes to glass components, even the slightest imperfection can detract from the overall quality of the piece. Precision cutting ensures that every glass element fits perfectly within the furniture design, contributing to the seamless, high-quality finish that discerning customers expect from luxury furniture.

One of the key advantages of precision cutting in high-end furniture manufacturing is the ability to achieve tight tolerances. Advanced glass cutting machines can cut glass to exact specifications, often with tolerances as small as a fraction of a millimeter. This level of precision is crucial when creating furniture with complex joinery or when integrating glass elements with other materials such as wood or metal.

Precision cutting also plays a vital role in creating perfectly matched patterns in glass furniture. For instance, in a glass-fronted cabinet with multiple doors, the grain or pattern in the glass needs to align perfectly across all panels. This level of matching can only be achieved through highly precise cutting techniques, ensuring a cohesive and luxurious appearance.

Furthermore, precision cutting with a furniture cabinet glass cutting machine made in China is essential for creating custom-shaped glass pieces that are often featured in high-end furniture designs. Whether it's a uniquely shaped glass tabletop or a curved glass panel for a designer cabinet, the ability to cut glass to exact specifications allows furniture manufacturers to realize innovative and avant-garde designs.

The role of precision cutting extends beyond just the cutting process itself. It also encompasses the preparation of the glass edges. High-end furniture often requires glass with perfectly polished edges, free from any chips or imperfections. Advanced glass cutting machines are equipped with edge processing capabilities that can achieve a high-quality finish, contributing to the overall luxurious feel of the furniture piece.

In the production of high-end glass furniture, precision cutting also plays a crucial role in ensuring structural integrity and safety. Accurately cut glass pieces fit together seamlessly, reducing stress points and the risk of breakage. This is particularly important for furniture items that bear significant weight or are subject to frequent use.

The precision offered by advanced glass cutting technology also allows for the incorporation of complex functional elements in high-end furniture. For example, precisely cut glass can be used to create smooth-sliding drawer fronts or perfectly fitting glass shelves within a cabinet. These functional elements contribute to the overall user experience of the furniture, enhancing its perceived value and quality.

Moreover, precision cutting enables the efficient use of high-value materials often used in luxury furniture. Expensive or rare types of glass can be cut with minimal waste, ensuring that these premium materials are used to their full potential. This not only contributes to cost efficiency but also aligns with the sustainability concerns that are increasingly important in high-end furniture manufacturing.

The role of precision cutting in high-end furniture manufacturing also extends to the realm of customization. With the ability to cut glass to exact specifications, furniture manufacturers can offer bespoke pieces tailored to individual client preferences. This level of customization is a hallmark of luxury furniture, allowing discerning customers to own truly unique pieces.

Conclusion

The integration of advanced glass cutting technology, particularly the furniture cabinet glass cutting machine, has undeniably transformed the furniture industry. From speeding up production cycles through automation to enabling complex designs with CNC capabilities, and ensuring the precision necessary for high-end manufacturing, these machines have become indispensable tools in modern furniture production.

As we've explored, the benefits are multifaceted. Improved efficiency, reduced waste, enhanced design possibilities, and the ability to maintain consistently high quality are just a few of the advantages that furniture manufacturers are reaping. These advancements not only benefit the manufacturers but also translate into superior products for consumers, pushing the boundaries of what's possible in furniture design and functionality.

If you're in the furniture manufacturing industry and haven't yet embraced the potential of advanced glass cutting technology, now is the time to consider how it could elevate your production processes and end products. At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge glass cutting solutions tailored to the needs of the furniture industry. Our years of experience in production and export, coupled with our commitment to advanced techniques and stable quality, have made us a trusted partner for furniture manufacturers worldwide.

Ready to take your furniture production to the next level? Reach out to us at salescathy@sdhuashil.com to discuss how our advanced glass cutting machines can benefit your business. Let's work together to shape the future of furniture manufacturing!

References

1. Smith, J. (2023). "Advanced Glass Cutting Technologies in Modern Furniture Manufacturing". Journal of Furniture Technology, 45(2), 78-92.

2. Johnson, A. & Lee, M. (2022). "The Impact of CNC Technology on Custom Furniture Design". International Review of Industrial Design, 18(4), 301-315.

3. Brown, R. (2023). "Automation and Efficiency in Glass Processing for the Furniture Industry". Glass Technology Quarterly, 67(3), 112-126.

4. Zhang, L. et al. (2022). "Precision Cutting Techniques in High-End Furniture Production: A Comprehensive Review". Luxury Goods Research, 9(1), 45-60.