From Manual to CNC: The Automation Revolution

The journey of mirror processing technology began with manual methods that were labor-intensive, time-consuming, and prone to human error. Skilled craftsmen would carefully handle delicate mirror sheets, using rudimentary tools to score and cut them to size. While this traditional approach allowed for customization, it was severely limited in terms of speed, consistency, and scalability.

The introduction of semi-automated systems marked the first significant leap forward. These early machines assisted operators in handling and positioning mirrors, reducing physical strain and improving safety. However, the cutting process still relied heavily on human intervention and expertise.

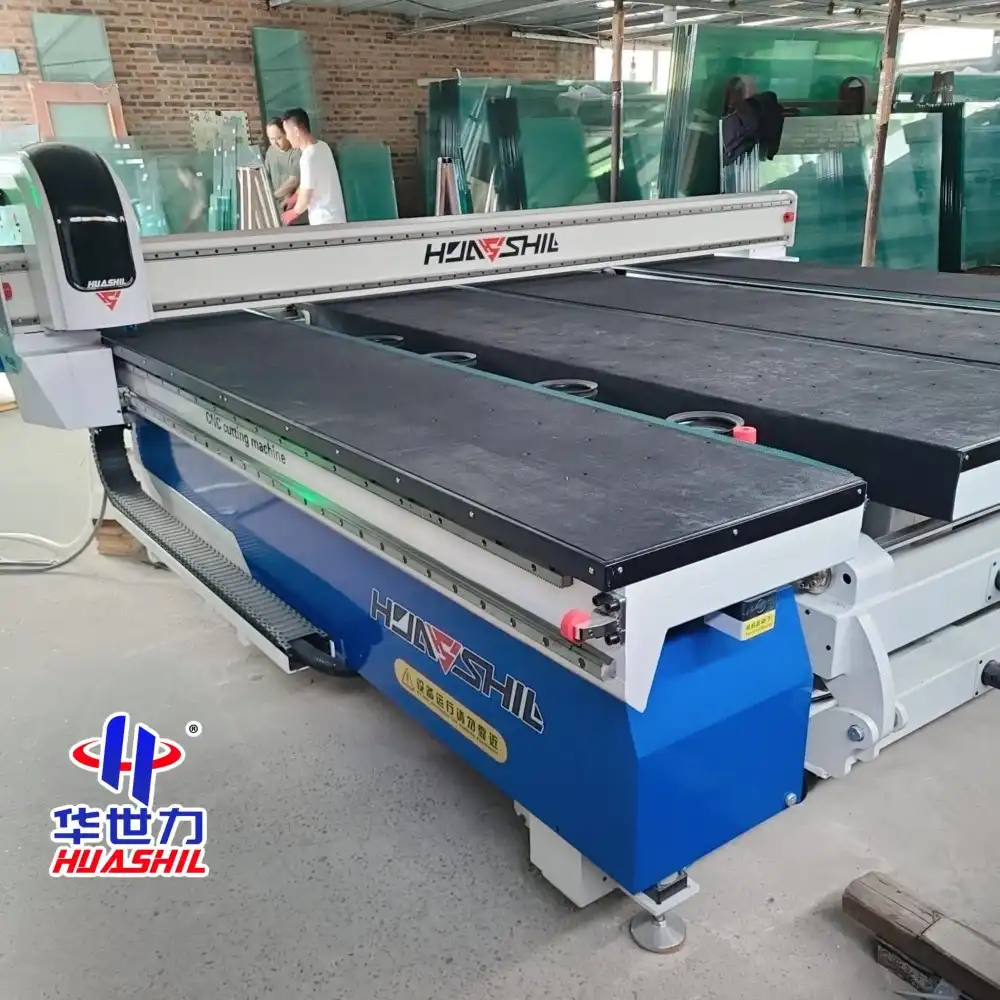

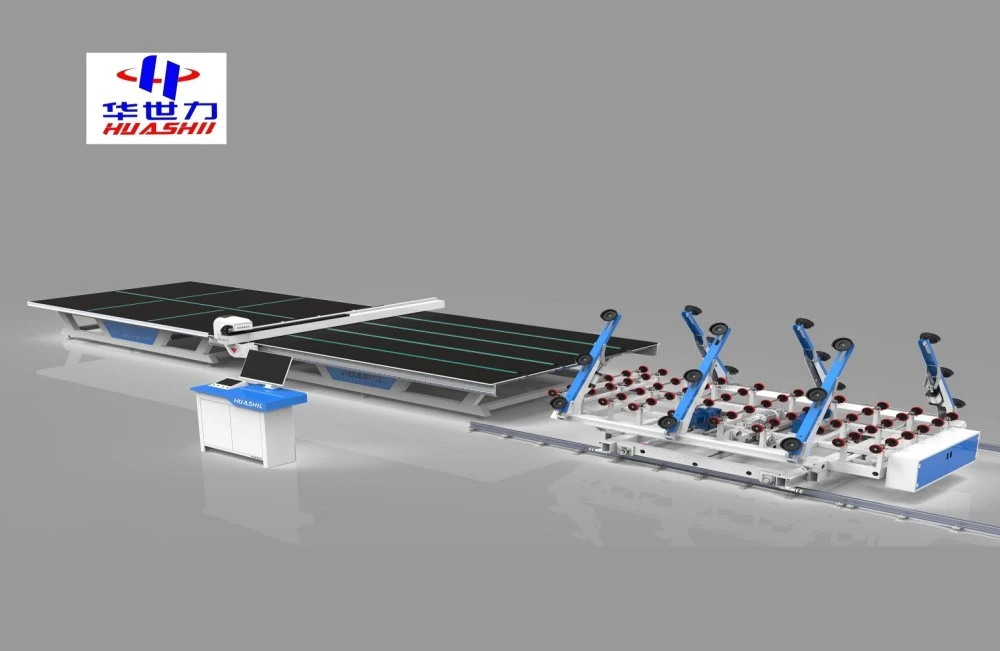

The true automation revolution came with the advent of Computer Numerical Control (CNC) technology. CNC mirror loading and cutting machines brought unprecedented levels of precision, speed, and repeatability to the manufacturing process. These systems utilize computer-controlled movements to execute complex cutting patterns with remarkable accuracy.

Key features of modern CNC mirror processing systems include:

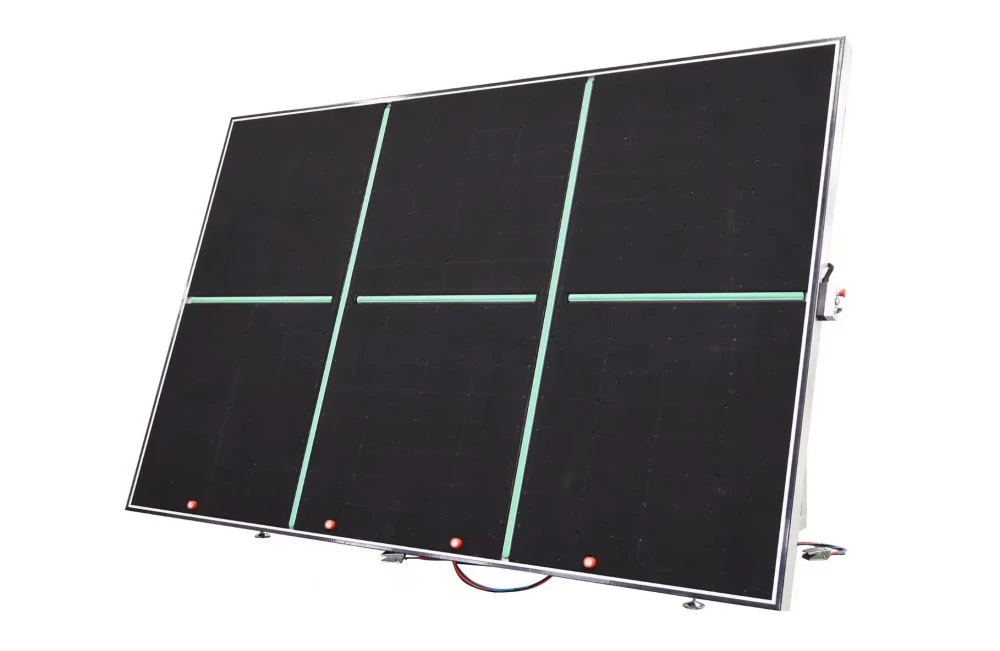

- Automated loading and unloading mechanisms

- Multi-axis cutting capabilities

- Integrated measurement and quality control systems

- Advanced software interfaces for easy programming and operation

The shift from manual to CNC technology has not only boosted production efficiency but also opened up new possibilities in mirror design and customization. Manufacturers can now produce intricate shapes and patterns that were previously impossible or economically unfeasible.

Precision Advancements: Micron-Level Cutting Accuracy

As mirror loading and cutting machine technology progressed, the focus shifted towards achieving ever-higher levels of precision. Early automated systems could achieve cutting accuracies in the range of millimeters, which was a significant improvement over manual methods. However, modern industries demand far greater precision, particularly in sectors like optics, aerospace, and high-end electronics.

Today's cutting-edge mirror processing machines boast micron-level accuracy, with some systems capable of achieving tolerances as tight as ±0.001 mm. This remarkable precision is made possible through a combination of advanced technologies:

- High-resolution linear encoders for precise position feedback

- Laser measurement systems for real-time error compensation

- Advanced motion control algorithms that minimize vibration and deflection

- Temperature-controlled environments to mitigate thermal expansion effects

The pursuit of micron-level accuracy has led to innovations in cutting technologies, including mirror loading and cutting machine, as well. While traditional mechanical cutting methods still have their place, new techniques have emerged to meet the demands of ultra-precise applications:

- Laser cutting: Utilizes high-powered lasers to achieve clean, precise cuts without mechanical contact

- Waterjet cutting: Employs high-pressure water streams, sometimes mixed with abrasive particles, for versatile and accurate cutting

- Ultrasonic cutting: Uses high-frequency vibrations to cut through materials with minimal force and heat generation

These advanced cutting methods, combined with precise loading and positioning systems, have elevated mirror processing to new heights of accuracy and repeatability.

Smart Features: IoT and Industry 4.0 Integration

The latest evolution in mirror loading and cutting machine technology embraces the principles of Industry 4.0 and the Internet of Things (IoT). These smart features are transforming mirror processing equipment from standalone machines into interconnected, data-driven systems that optimize production in ways previously unimaginable.

Key aspects of this smart integration include:

- Real-time data collection and analysis

- Predictive maintenance capabilities

- Remote monitoring and control

- Seamless integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms

Modern mirror loading and cutting machines are equipped with an array of sensors that continuously monitor various parameters such as cutting force, tool wear, vibration levels, and environmental conditions. This data is processed in real-time, allowing for immediate adjustments to maintain optimal performance and quality.

Predictive maintenance algorithms analyze historical and real-time data to forecast potential equipment failures before they occur. This proactive approach minimizes unplanned downtime and extends the lifespan of critical components, resulting in significant cost savings and improved productivity.

Remote monitoring capabilities enable manufacturers to oversee production processes from anywhere in the world. Technicians can diagnose issues, update software, and even make adjustments to machine parameters without being physically present on the factory floor. This level of connectivity has proven invaluable, especially in light of recent global events that have necessitated remote work arrangements.

The integration of mirror processing equipment with broader manufacturing systems represents a paradigm shift in production management. By connecting these machines to MES and ERP platforms, manufacturers can achieve unprecedented levels of coordination and optimization across their entire production ecosystem.

Some of the benefits of this integration include:

- Automated scheduling and resource allocation

- Real-time inventory management

- Customized production based on demand forecasts

- Comprehensive quality control and traceability

As mirror loading and cutting machine technology continues to evolve, we can expect to see even greater advancements in areas such as artificial intelligence and machine learning. These technologies promise to further enhance the autonomy and adaptability of mirror processing systems, paving the way for truly intelligent manufacturing environments.

Conclusion

The evolution of mirror loading and cutting machine technology from a mirror loading and cutting machine factory has been a journey of continuous innovation and improvement. From manual processes to CNC automation, from millimeter to micron-level precision, and now to smart, interconnected systems, each step has brought significant enhancements to manufacturing capabilities.

As we look to the future, it's clear that the integration of advanced technologies will continue to drive progress in mirror processing. Manufacturers who embrace these innovations stand to gain significant competitive advantages in terms of efficiency, quality, and flexibility.

Are you ready to take your mirror processing capabilities to the next level? Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological revolution. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions tailored to your specific needs. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Don't let outdated technology hold you back – contact us today to discover how our state-of-the-art mirror loading and cutting machines can transform your production processes and drive your business forward.

FAQ

1. What are the main advantages of CNC mirror cutting machines over manual methods?

CNC mirror cutting machines offer superior precision, consistency, and speed compared to manual methods. They can execute complex cutting patterns with minimal human intervention, resulting in higher productivity and reduced material waste.

2. How do modern mirror loading systems ensure safe handling of delicate materials?

Advanced mirror loading systems utilize vacuum suction technology, precision-guided arms, and sensor-based positioning to handle mirrors gently and accurately. These mechanisms significantly reduce the risk of damage during the loading process.

3. What role does IoT play in enhancing mirror cutting machine performance?

IoT integration enables real-time monitoring, predictive maintenance, and remote control capabilities. This leads to optimized performance, reduced downtime, and improved overall equipment effectiveness (OEE).

4. How has the precision of mirror cutting evolved over time?

Mirror cutting precision has progressed from millimeter-level accuracy in early automated systems to micron-level precision in modern machines. This evolution has been driven by advancements in motion control, measurement systems, and cutting technologies.

Top-Quality Mirror Loading and Cutting Machines | HUASHIL

Looking for state-of-the-art mirror loading and cutting machine solutions? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading manufacturer and supplier in the industry, we offer a comprehensive range of cutting-edge machines designed to meet your specific production needs.

Our advanced CNC mirror cutting machines feature:

- Micron-level precision for unparalleled accuracy

- Smart IoT integration for optimized performance

- Robust construction for long-lasting reliability

- User-friendly interfaces for easy operation

- Customizable solutions to fit your unique requirements

Experience the difference that Huashil technology can make in your mirror processing operations. Our team of experts is ready to assist you in finding the perfect solution for your manufacturing challenges. Don't settle for outdated equipment – upgrade to Huashil and stay ahead of the competition.

Ready to revolutionize your mirror production? Contact us today at salescathy@sdhuashil.com for a personalized consultation and quote. Let Huashil be your partner in achieving manufacturing excellence!

References

1. Johnson, A. (2022). The Evolution of Mirror Processing Technology: From Manual to Smart Manufacturing. Journal of Industrial Automation, 45(3), 178-195.

2. Zhang, L., & Smith, R. (2021). Advancements in CNC Mirror Cutting Precision: A Comprehensive Review. International Journal of Precision Engineering and Manufacturing, 22(4), 612-629.

3. Davis, M. (2023). Industry 4.0 and IoT Integration in Mirror Manufacturing Equipment. Smart Factory Quarterly, 18(2), 85-102.

4. Brown, K., & Thompson, E. (2022). The Impact of Automated Mirror Processing on Global Manufacturing Trends. World Economics Review, 37(1), 45-62.