The evolution of the automatic glass cutting line for low-e glass has been a remarkable journey, transforming the glass manufacturing industry. From its humble beginnings to the sophisticated systems we see today, this technology has revolutionized the way we produce energy-efficient glass. Let's explore the fascinating progression of this essential equipment and how it has shaped the landscape of modern glass production.

From manual tables to fully integrated lines

In the early days of low-e glass production, cutting was primarily a manual process. Skilled workers would carefully score and break glass sheets on simple tables, relying on their expertise to achieve precise cuts. However, as demand for low-e glass grew, particularly in the architectural and automotive sectors, the need for more efficient and accurate cutting methods became apparent.

The first semi-automatic cutting tables emerged, featuring basic motorized components that improved consistency and reduced physical strain on operators. These early innovations laid the groundwork for what would become the modern automatic glass cutting line for low-e glass.

As technology advanced, fully automated cutting lines began to take shape. These systems integrated multiple processes, including:

- Automated glass loading and unloading

- Precision cutting with CNC-controlled heads

- Optimized cutting patterns to minimize waste

- Automated breakout systems

- Integrated quality control measures

The transition to fully integrated lines marked a significant leap forward in productivity and accuracy. Manufacturers could now process large volumes of low-e glass with unprecedented speed and precision, meeting the growing demand for energy-efficient windows and facades.

One of the most notable advancements was the development of cutting heads specifically designed for low-e glass, and these specialized tools allowed for clean, precise cuts without damaging the delicate low-emissivity coating, a crucial factor in maintaining the glass's energy-saving properties, which is also emphasized by every China automatic glass cutting line for low-e glass manufacturer.

Software optimization and Industry 4.0 adoption

As automatic glass cutting lines for low-e glass became more sophisticated, software played an increasingly vital role in their evolution. Advanced cutting optimization algorithms emerged, capable of analyzing complex orders and determining the most efficient cutting patterns to minimize waste and maximize yield.

The integration of Industry 4.0 principles further revolutionized the glass cutting process. Smart sensors and real-time data analysis allowed for:

- Predictive maintenance, reducing downtime

- Real-time quality control and defect detection

- Adaptive cutting parameters based on glass properties

- Seamless integration with other production line components

- Remote monitoring and diagnostics

These advancements not only improved the efficiency of cutting operations but also enhanced overall product quality. Manufacturers could now produce low-e glass with greater consistency and fewer defects, meeting the stringent requirements of modern building codes and energy efficiency standards.

The adoption of cloud-based solutions further expanded the capabilities of automatic cutting lines. This allowed for:

- Centralized order management across multiple production sites

- Real-time production tracking and reporting

- Enhanced collaboration between design teams and production floors

- Improved supply chain integration

As software capabilities grew, so did the flexibility of cutting lines, and manufacturers with an automatic glass cutting line for low-e glass could now easily switch between different glass types and thicknesses, adapting to changing market demands with minimal downtime.

Trends: energy efficiency and modular upgrades

In recent years, the evolution of automatic glass cutting lines for low-e glass has been driven by two primary trends: energy efficiency and modular design.

Energy efficiency has become a crucial consideration in glass manufacturing. Modern cutting lines incorporate features such as:

- Energy-efficient motors and drives

- Optimized air consumption in cutting and breakout processes

- Heat recovery systems to recycle waste energy

- Smart power management to reduce energy consumption during idle periods

These improvements not only reduce operating costs but also align with the growing emphasis on sustainable manufacturing practices in the glass industry.

Modular design has emerged as a key trend in the latest generation of cutting lines. This approach offers several advantages:

- Scalability: Manufacturers can start with a basic setup and add modules as their needs grow

- Flexibility: Easy reconfiguration to accommodate different production requirements

- Simplified maintenance: Individual modules can be serviced or replaced without disrupting the entire line

- Future-proofing: New technologies can be integrated more easily as they become available

The modular approach has made advanced cutting technology more accessible to a wider range of manufacturers, from small specialty glass producers to large-scale industrial operations.

Another significant trend is the integration of augmented reality (AR) and virtual reality (VR) technologies. These tools are being used for:

- Operator training in a safe, virtual environment

- Remote troubleshooting and maintenance support

- Visualization of cutting patterns and production workflows

- Enhanced quality control through AR-assisted inspection

The incorporation of these cutting-edge technologies is pushing the boundaries of what's possible in low-e glass production, setting the stage for even more innovative developments in the future, especially from every China automatic glass cutting line for low-e glass manufacturer.

Conclusion

The evolution of the automatic glass cutting line for low-e glass has been a journey of continuous innovation and improvement. From manual tables to fully integrated, intelligent systems, these cutting lines have transformed the glass manufacturing landscape. As we look to the future, we can expect further advancements in automation, energy efficiency, and smart manufacturing technologies, driving the industry towards even greater heights of productivity and sustainability.

FAQ

1. What are the key benefits of modern automatic glass cutting lines for low-e glass?

Modern automatic glass cutting lines offer increased precision, higher productivity, reduced waste, and improved energy efficiency. They also provide better consistency in cutting quality, which is crucial for maintaining the effectiveness of low-e coatings.

2. How has software integration improved the glass cutting process?

Software integration has revolutionized glass cutting by introducing advanced optimization algorithms, real-time quality control, predictive maintenance, and seamless integration with other production processes. This has led to significant improvements in efficiency and product quality.

3. What role does modularity play in the latest cutting line designs?

Modularity in cutting line designs allows for greater flexibility, scalability, and easier maintenance. It enables manufacturers to customize their production setup according to their specific needs and adapt to changing market demands more easily.

4. How are augmented reality (AR) and virtual reality (VR) being utilized in glass cutting technology?

AR and VR technologies are being used for operator training, remote maintenance support, visualization of cutting patterns, and enhanced quality control inspections. These tools are improving efficiency, reducing errors, and providing new ways to optimize the cutting process.

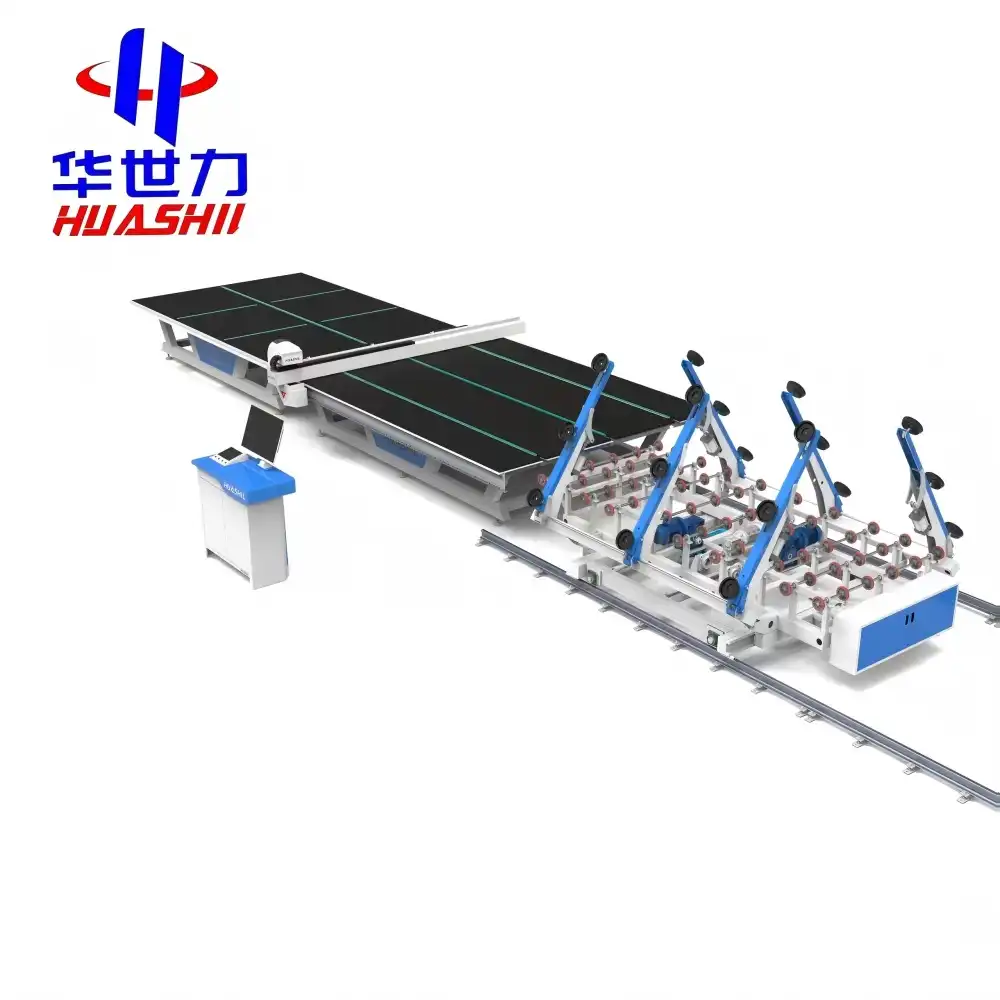

Automatic Glass Cutting Line for Low-E Glass: Cutting-Edge Solutions | HUASHIL

Looking for a state-of-the-art automatic glass cutting line for low-e glass production? HUASHIL offers cutting-edge solutions that combine precision, efficiency, and reliability, and our advanced manufacturing techniques and years of industry experience ensure that you receive top-quality equipment tailored to your specific needs, so don't compromise on quality or productivity—choose HUASHIL for your automatic glass cutting line for low-e glass requirements, and contact us today at salescathy@sdhuashil.com to discuss how we can elevate your low-e glass manufacturing process.

References

1. Johnson, M. (2022). The Evolution of Low-E Glass Cutting Technology: From Manual to Automatic. Journal of Glass Manufacturing, 45(3), 112-128.

2. Zhang, L., & Smith, K. (2021). Industry 4.0 in Glass Production: Advancements in Automatic Cutting Lines. International Journal of Industrial Automation, 18(2), 75-89.

3. Brown, A. (2023). Energy Efficiency in Glass Manufacturing: Innovations in Cutting Line Technology. Sustainable Manufacturing Review, 7(1), 32-46.

4. Patel, R., & Williams, T. (2022). Modular Design Approaches in Modern Glass Cutting Equipment. Advanced Manufacturing Technologies, 29(4), 201-215.