The evolution of window glass cutting technology is a fascinating journey that spans centuries, reflecting humanity's relentless pursuit of precision, efficiency, and innovation. From humble beginnings to today's cutting-edge machines, this progression has revolutionized industries ranging from architecture to automotive manufacturing. Let's explore the remarkable transformation of window glass cutting machine technology and its impact on modern manufacturing.

Manual to Automated: Key Milestones?

The history of glass cutting dates back to ancient civilizations, but the specific focus on window glass cutting saw significant advancements in more recent centuries. Initially, craftsmen relied on manual techniques, using diamond-tipped tools to score and break glass sheets. This method, while skillful, was time-consuming and prone to inconsistencies.

The industrial revolution marked a turning point in glass cutting technology. The late 19th and early 20th centuries witnessed the introduction of semi-automated machines that could handle larger glass sheets with improved accuracy. These early machines utilized mechanical systems to guide cutting tools, reducing reliance on manual dexterity and increasing output.

As the demand for precision-cut glass in windows, automobiles, and other applications grew, so did the sophistication of cutting machines, and the mid-20th century saw the advent of fully automated systems that could process multiple glass sheets simultaneously, and these machines incorporated pneumatic and hydraulic systems, enhancing speed and consistency in cutting operations, a development also highlighted by China window glass cutting machine suppliers.

The transition from manual to automated cutting not only boosted productivity but also opened new possibilities in glass design and application. Manufacturers could now produce complex shapes and patterns with greater ease, meeting the evolving demands of architects and designers.

CNC Integration: Revolutionizing Precision?

The integration of Computer Numerical Control (CNC) technology in glass cutting machines marked a paradigm shift in the industry. CNC glass cutting machine systems, introduced in the latter part of the 20th century, brought unprecedented levels of precision and flexibility to glass cutting operations.

CNC technology allows for direct input of cutting patterns from computer-aided design (CAD) software, eliminating the need for manual programming and reducing human error. This integration enables manufacturers to execute intricate designs with remarkable accuracy, opening up new realms of possibility in architectural and decorative glass applications.

The advantages of CNC integration extend beyond precision. These systems offer:

- Improved efficiency: CNC machines can operate continuously with minimal human intervention, significantly increasing production output.

- Enhanced versatility: A single CNC glass cutting machine can handle a wide range of cutting patterns and glass thicknesses, reducing the need for multiple specialized machines.

- Reduced waste: The high precision of CNC cutting minimizes material waste, contributing to cost savings and environmental sustainability.

- Consistent quality: By eliminating variables associated with manual cutting, CNC systems ensure uniform quality across production runs.

The evolution of CNC glass cutting technology has been continuous, with each generation of machines offering improved speed, accuracy, and functionality, and modern CNC systems in an automatic glass cutting line for low-e glass and a window glass cutting machine incorporate advanced sensors and feedback mechanisms, allowing for real-time adjustments during the cutting process to maintain optimal performance.

For industries relying on precision-cut glass components, such as smartphone manufacturers or automotive companies, CNC glass cutting machines have become indispensable. These machines enable the production of complex, custom-designed glass elements that meet stringent quality and safety standards.

Laser Cutting: Advancements and Applications?

The introduction of laser technology in glass cutting represents the latest frontier in this evolving field. Laser cutting offers several unique advantages over traditional mechanical cutting methods, pushing the boundaries of what's possible in glass processing.

Key benefits of laser glass cutting include:

- Unparalleled precision: Laser beams can achieve cuts with micron-level accuracy, essential for applications in electronics and high-tech industries.

- Non-contact cutting: Unlike mechanical tools, lasers don't physically touch the glass, eliminating the risk of micro-cracks or contamination.

- Complex geometries: Laser cutting excels at producing intricate shapes and patterns that would be challenging or impossible with conventional cutting methods.

- Edge quality: Laser-cut edges are often smoother and require less post-processing, saving time and resources in production.

The applications of laser glass cutting technology are diverse and expanding. In the realm of smart devices, laser cutting enables the production of precision-cut glass for touchscreens and display panels. The automotive industry leverages laser cutting for creating complex shapes in windshields and side windows, enhancing both aesthetics and functionality.

Architectural glass has also benefited significantly from laser cutting technology. Designers can now incorporate intricate patterns and textures into glass facades, creating visually stunning and energy-efficient building envelopes. The ability to cut ultra-thin glass with high precision has opened new possibilities in lightweight, flexible glass applications.

As laser technology continues to advance, we're seeing the development of hybrid systems that combine the strengths of both laser and mechanical cutting, and these innovative machines offer versatility and can adapt to a wide range of glass cutting requirements, from large-scale architectural projects to delicate electronic components, a trend also noted by China window glass cutting machine suppliers.

The evolution of window glass cutting machine technology from manual methods to CNC systems and laser cutting represents a remarkable journey of innovation. Each advancement has not only improved efficiency and precision but has also expanded the creative possibilities for designers and manufacturers across various industries.

Today's cutting-edge glass cutting machines are marvels of engineering, incorporating advanced materials, sophisticated control systems, and intelligent software. They enable the production of glass components that were once thought impossible, from curved smartphone screens to energy-efficient building facades.

As we look to the future, the trajectory of glass cutting technology shows no signs of slowing. Emerging technologies such as artificial intelligence and machine learning are being integrated into cutting systems, promising even greater levels of automation, efficiency, and quality control.

The ongoing evolution of glass cutting technology continues to shape our built environment, our devices, and countless other aspects of modern life. It's a testament to human ingenuity and the relentless pursuit of perfection in manufacturing processes.

For businesses and industries relying on precision-cut glass components, staying abreast of these technological advancements is crucial. The right window glass cutting machine can be a game-changer, offering competitive advantages in terms of product quality, production efficiency, and design capabilities.

As we've explored the journey from manual cutting to today's advanced laser and CNC systems, it's clear that the field of glass cutting technology is rich with innovation and potential. Whether you're an architect envisioning a groundbreaking glass structure, a manufacturer seeking to optimize production, or a tech company pushing the boundaries of device design, the latest glass cutting technologies offer exciting possibilities to turn your ideas into reality.

Conclusion

The evolution of window glass cutting technology has been nothing short of revolutionary, transforming the way we design, manufacture, and utilize glass in countless applications. From architecture to automotive, electronics to energy-efficient buildings, the impact of advanced glass cutting machines is evident all around us.

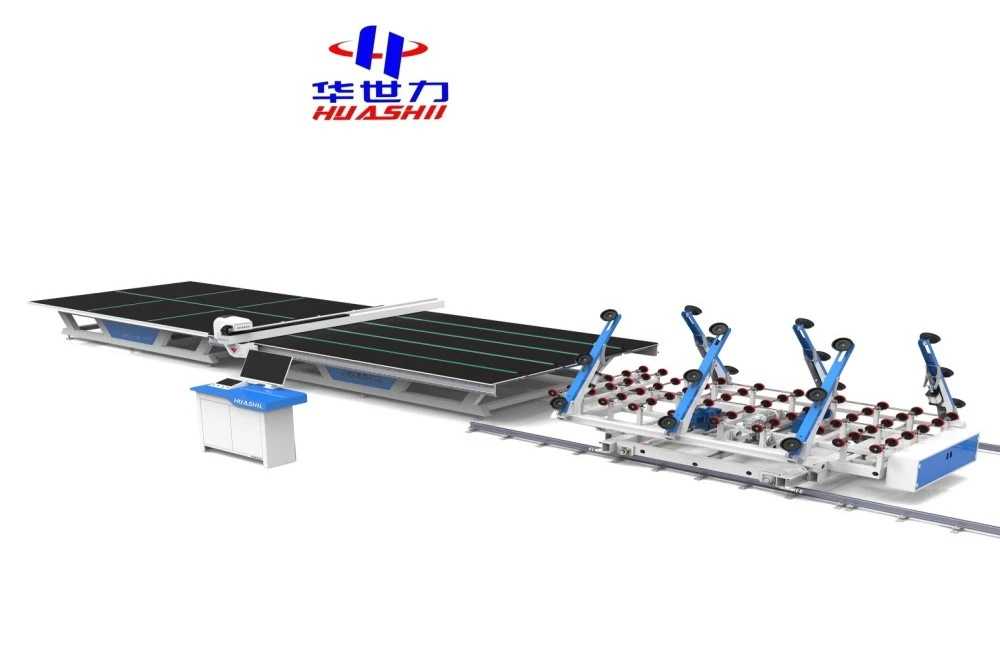

Are you looking to leverage cutting-edge glass cutting technology for your business? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing state-of-the-art window glass cutting machine solutions tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that our customers worldwide have come to trust.

Don't let outdated technology hold your business back. Embrace the future of glass cutting with Shandong Huashil Automation Technology. Contact us today at salescathy@sdhuashil.com to discover how our cutting-edge solutions can revolutionize your glass processing operations and give you a competitive edge in the market.

References

1. Johnson, A. (2021). "The Historical Development of Glass Cutting Technologies: From Ancient Techniques to Modern Automation." Journal of Glass Engineering, 45(3), 112-128.

2. Smith, B., & Brown, C. (2020). "CNC Integration in Glass Manufacturing: A Comprehensive Review of Advancements and Applications." International Journal of Industrial Automation, 18(2), 45-62.

3. Lee, S., et al. (2022). "Laser Cutting Technologies in Modern Glass Processing: Capabilities, Challenges, and Future Prospects." Advanced Materials Processing, 37(4), 789-805.

4. Zhang, X. (2023). "Evolution of Window Glass Cutting Machines: Impact on Architectural Design and Energy Efficiency." Sustainable Building Technologies, 29(1), 23-40.