Selecting the right automatic glass cutting machine is a crucial decision for any glass manufacturing or processing business. This advanced equipment can significantly enhance productivity, precision, and overall efficiency in your operations. However, with numerous options available in the market, making the right choice can be challenging. This comprehensive guide will walk you through the essential factors to consider when choosing an automatic glass cutting machine, ensuring you make an informed decision that aligns with your specific needs and business goals.

Production Volume Requirements Assessment

Before diving into the technical specifications of various machines, it's imperative to assess your production volume requirements. This evaluation forms the foundation of your decision-making process and helps narrow down your options to machines that can effectively meet your output needs.

Start by analyzing your current production volumes and projected growth. Consider the following questions:

- What is your average daily or weekly glass cutting volume?

- Do you experience seasonal fluctuations in demand?

- What are your growth projections for the next 3-5 years?

- Do you need to handle multiple glass types or sizes simultaneously?

Once you have a clear understanding of your production needs, you can focus on machines that offer the appropriate cutting speed and capacity. For instance, if you're a small to medium-sized operation, a machine with a cutting speed of 80-120 m/min might suffice. However, for larger enterprises with high-volume production, you might need to consider machines with cutting speeds of 150 m/min or higher.

It's also worth noting that some automatic glass cutting machines offer modular designs, allowing for future upgrades or expansions. This feature can be particularly beneficial if you anticipate significant growth in your production volumes over time.

Additionally, consider the machine's ability to handle different glass sizes. Some machines are designed for standard glass sheets, while others can accommodate jumbo sizes. Ensure the machine you choose can handle your current and future size requirements without compromising on efficiency or quality.

Lastly, evaluate the machine's cycle time – the total time it takes to complete one cutting operation, including loading, cutting, and unloading. A machine with a shorter cycle time can significantly boost your overall productivity, especially in high-volume production environments.

Material Thickness Compatibility Factors

The versatility of an automatic glass cutting machine in terms of material thickness compatibility is a critical factor that can significantly impact your production capabilities and flexibility. Different glass products require varying thicknesses, and your chosen machine should be able to accommodate your specific needs.

When evaluating material thickness compatibility, consider the following aspects:

- Range of Thickness: Look for a machine that can handle the full range of glass thicknesses you work with. Some machines are designed for thin glass (2-6 mm), while others can cut thicker glass up to 19 mm or more.

- Precision Across Thicknesses: Ensure the machine maintains high cutting precision across different thicknesses. Some machines may excel at cutting thin glass but lose accuracy when dealing with thicker materials.

- Tool Adaptability: Check if the machine allows for easy changing of cutting tools to accommodate different glass thicknesses. This feature can save time and increase efficiency in operations that frequently switch between different glass types.

- Pressure Adjustment: Advanced automatic glass cutting machines often feature automatic pressure adjustment systems that optimize cutting pressure based on glass thickness. This ensures consistent quality across various materials.

It's also crucial to consider the types of glass you'll be working with. Some machines are optimized for float glass, while others can handle a wider variety of glass types, including laminated, coated, or even curved glass. If your production involves specialty glass types, ensure the machine you choose is compatible with these materials.

Another important factor is the machine's ability to perform deep cuts or score-and-snap operations for thicker glass. Some machines offer adjustable cutting depths, allowing for more versatility in your production process.

Lastly, consider the machine's breakout system. For thicker glass, a robust breakout system is essential to ensure clean, precise breaks without damaging the glass or compromising safety. Look for machines with pneumatic or hydraulic breakout systems that can handle your thickest glass requirements.

Evaluating After-Sales Service and Support

While the technical specifications of an automatic glass cutting machine are crucial, the quality of after-sales service and support can be equally important in ensuring long-term satisfaction and optimal performance of your investment. A comprehensive support system can minimize downtime, extend the machine's lifespan, and help you maximize its capabilities.

When evaluating after-sales service and support, consider the following factors:

- Warranty Coverage: Look for machines that come with robust warranty coverage. A comprehensive warranty can protect you from unexpected repair costs and demonstrate the manufacturer's confidence in their product.

- Availability of Spare Parts: Ensure that spare parts are readily available and can be shipped quickly when needed. Some manufacturers maintain local inventories of common spare parts, which can significantly reduce downtime in case of breakdowns.

- Technical Support: Assess the manufacturer's technical support capabilities. Do they offer 24/7 support? Can they provide remote diagnostics and troubleshooting? The ability to quickly resolve issues can be crucial in maintaining production schedules.

- Training Programs: Look for manufacturers that offer comprehensive training programs for your operators and maintenance staff. This can help you maximize the machine's capabilities and ensure proper operation and maintenance.

- Preventive Maintenance Plans: Some manufacturers offer preventive maintenance plans that include regular inspections and servicing. These plans can help prevent unexpected breakdowns and extend the machine's lifespan.

- Software Updates: For automatic glass cutting machines with advanced software systems, regular updates can improve performance and add new features. Check if the manufacturer provides software updates and how frequently they're released.

It's also worth considering the manufacturer's track record in the industry. A company with a long history of producing glass cutting equipment is likely to have a more extensive support network and a better understanding of customer needs.

Don't hesitate to ask for references from other customers who have purchased the same or similar machines. Their experiences can provide valuable insights into the quality of after-sales support and the machine's long-term performance.

Lastly, consider the manufacturer's commitment to innovation and continuous improvement. A company that invests in research and development is more likely to offer cutting-edge solutions and stay ahead of industry trends, ensuring that your investment remains competitive in the long run.

Conclusion

Choosing the right automatic glass cutting machine is a significant decision that can have a profound impact on your business's productivity, efficiency, and competitiveness. By carefully assessing your production volume requirements, considering material thickness compatibility factors, and evaluating after-sales service and support, you can make an informed decision that aligns with your specific needs and long-term goals.

Remember, the ideal machine is not necessarily the one with the most advanced features or the highest cutting speed, but the one that best fits your unique production environment and business objectives. Take the time to thoroughly research and compare different options, and don't hesitate to reach out to manufacturers for detailed information and demonstrations.

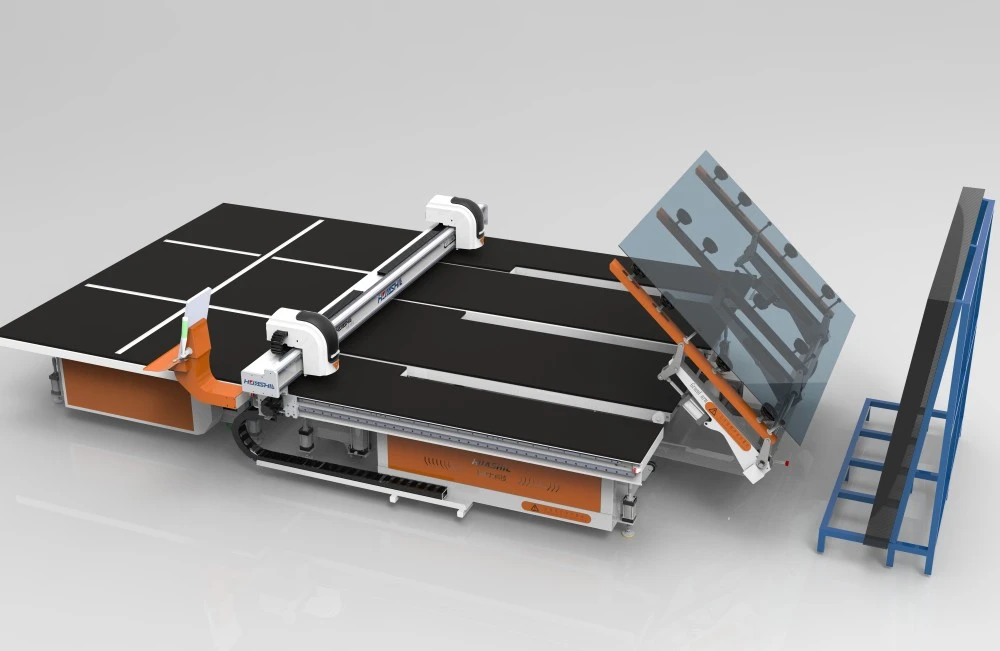

If you're looking for a reliable partner in automatic glass cutting technology, consider Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have earned the trust of customers worldwide. Our range of automatic glass cutting machines is designed to meet diverse production needs, from small-scale operations to large industrial setups.

Ready to take your glass cutting operations to the next level? Contact our team of experts at salescathy@sdhuashil.com for personalized advice and solutions tailored to your specific requirements. Let us help you choose the perfect automatic glass cutting machine that will drive your business forward.

References

1. Glass Industry Association. (2023). "Advancements in Automatic Glass Cutting Technology: A Comprehensive Guide"

2. Johnson, R. & Smith, A. (2022). "Optimizing Glass Manufacturing Processes: The Role of Automated Cutting Machines"

3. International Journal of Glass Processing. (2023). "Comparative Analysis of Automatic Glass Cutting Machines: Performance Metrics and Selection Criteria"

4. Wilson, M. (2022). "The Future of Glass Cutting: Trends and Innovations in Automatic Cutting Technologies"