Maintaining a cutting machine for glass is crucial for ensuring its longevity, precision, and efficiency. Whether you're in the architectural, automotive, or smart mirror industry, proper maintenance of your glass cutting equipment can save you time, money, and headaches in the long run. In this comprehensive guide, we'll explore the essential maintenance practices, troubleshooting tips, and the pros and cons of professional versus DIY maintenance for your glass cutting machine.

Essential daily maintenance checklist for longevity

To keep your glass cutting machine in top shape, it's important to establish a daily maintenance routine for cutting machine for glass. Here's a checklist of essential tasks to perform:

- Clean the cutting surface: Remove any glass debris, dust, or residue from the cutting table. Use a soft brush or vacuum cleaner to avoid scratching the surface.

- Inspect cutting wheels: Check for signs of wear or damage. Replace cutting wheels if they show signs of dulling or chipping.

- Lubricate moving parts: Apply appropriate lubricants to bearings, gears, and other moving components as specified in the machine's manual.

- Check alignment: Ensure that the cutting head and guides are properly aligned for accurate cuts.

- Verify coolant levels: If your machine uses a coolant system, check and replenish the coolant as needed.

- Inspect electrical connections: Look for any loose or frayed wires and tighten connections if necessary.

- Clean air filters: If your machine has air filters, clean or replace them regularly to maintain optimal performance.

- Check safety features: Test emergency stop buttons and other safety mechanisms to ensure they're functioning correctly.

- Calibrate sensors: Verify that all sensors are working properly and calibrate them if needed.

- Review software updates: Check for any available software updates for your machine's control system.

By incorporating these tasks into your daily routine, you can significantly extend the life of your glass cutting machine and maintain its cutting precision with cutting machine for glass. Remember, prevention is always better than cure when it comes to machinery maintenance.

Troubleshooting common issues in glass cutting machines

Even with regular maintenance, you may encounter some issues with your glass cutting machine for cutting machine for glass. Here are some common problems and their potential solutions:

Inaccurate cuts

If you notice that your cuts are not as precise as they should be, consider the following:

- Check the cutting wheel for wear and replace if necessary

- Verify the alignment of the cutting head and guides

- Ensure the glass is properly positioned and secured on the cutting table

- Calibrate the machine's measurement system

Excessive chipping or breakage

When your cuts result in more chips or breakage than usual, try these solutions:

- Adjust the cutting pressure

- Verify that you're using the correct cutting wheel for the glass type and thickness

- Check the cutting speed and adjust if necessary

- Ensure the cutting surface is clean and free of debris

Unusual noises or vibrations

If you hear strange sounds or feel excessive vibrations during operation:

- Inspect all moving parts for signs of wear or damage

- Check and tighten any loose bolts or connections

- Lubricate bearings and other moving components

- Verify that the machine is level and properly balanced

Software or control system issues

For problems related to the machine's software or control system of cutting machine for glass:

- Restart the system and check if the issue persists

- Verify that all cables and connections are secure

- Update the software to the latest version

- Contact the manufacturer's technical support for advanced troubleshooting

Coolant system problems

If you're experiencing issues with the coolant system:

- Check for leaks in the coolant lines

- Clean or replace clogged nozzles

- Verify that the coolant pump is functioning correctly

- Ensure the coolant mixture is at the correct concentration

By addressing these common issues promptly, you can minimize downtime and maintain the efficiency of your glass cutting machine. However, if problems persist or you're unsure about how to proceed, it's always best to consult with a professional technician.

Professional vs. DIY maintenance: making the right choice

When it comes to maintaining your cutting machine for glass, you have two main options: professional maintenance or do-it-yourself (DIY) upkeep. Each approach has its advantages and disadvantages, and the right choice depends on various factors such as your technical expertise, budget, and the complexity of your machine.

Professional Maintenance

Pros:

- Expertise: Trained technicians have in-depth knowledge of various glass cutting machines

- Comprehensive service: Professionals can perform thorough inspections and address potential issues before they become major problems

- Warranty protection: Using authorized service providers can help maintain your machine's warranty

- Time-saving: Professional maintenance allows you to focus on your core business operations

- Access to specialized tools: Technicians have access to specialized diagnostic and repair tools

Cons:

- Cost: Professional services can be more expensive than DIY maintenance

- Scheduling: You may need to work around the technician's availability

- Downtime: Your machine may be out of commission for longer periods during professional servicing

DIY Maintenance

Pros:

- Cost-effective: Performing maintenance yourself can save money on labor costs

- Immediate action: You can address issues as soon as they arise

- Familiarity: Regular DIY maintenance helps you become more familiar with your machine's operation

- Flexibility: You can perform maintenance at times that are convenient for your production schedule

Cons:

- Limited expertise: You may not have the specialized knowledge to diagnose complex issues

- Risk of mistakes: Incorrect maintenance procedures can potentially damage the machine

- Time-consuming: DIY maintenance takes time away from your other responsibilities

- Warranty concerns: Some manufacturers may void warranties if maintenance is not performed by authorized technicians

Making the Right Choice

To determine the best approach for your situation, consider the following factors:

- Machine complexity: More advanced machines may require professional expertise

- Your technical skills: Assess your ability to perform various maintenance tasks

- Budget: Compare the costs of professional services versus potential DIY mistakes

- Production demands: Consider how much downtime you can afford for maintenance

- Warranty requirements: Check your machine's warranty terms regarding maintenance

In many cases, a hybrid approach can be the most effective. Perform routine daily and weekly maintenance tasks yourself, while scheduling professional service for more complex procedures or annual check-ups. This strategy allows you to balance cost-effectiveness with the assurance of expert care for your valuable equipment.

Conclusion

Maintaining your cutting machine for glass is essential for ensuring its longevity, precision, and efficiency. By following a regular maintenance routine, troubleshooting common issues promptly, and making informed decisions about professional versus DIY maintenance, you can keep your glass cutting operations running smoothly and productively.

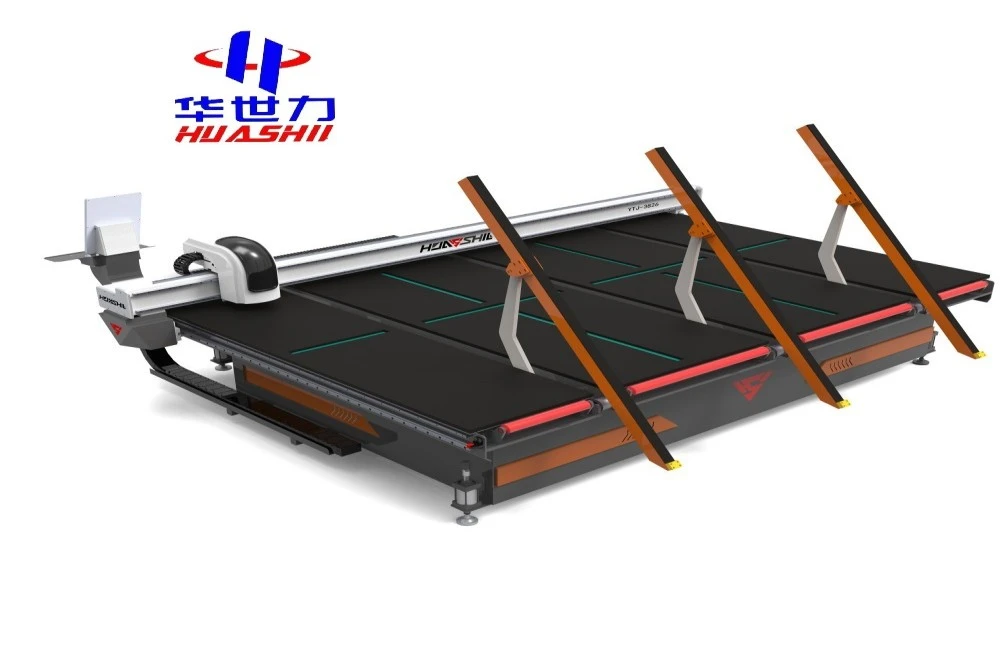

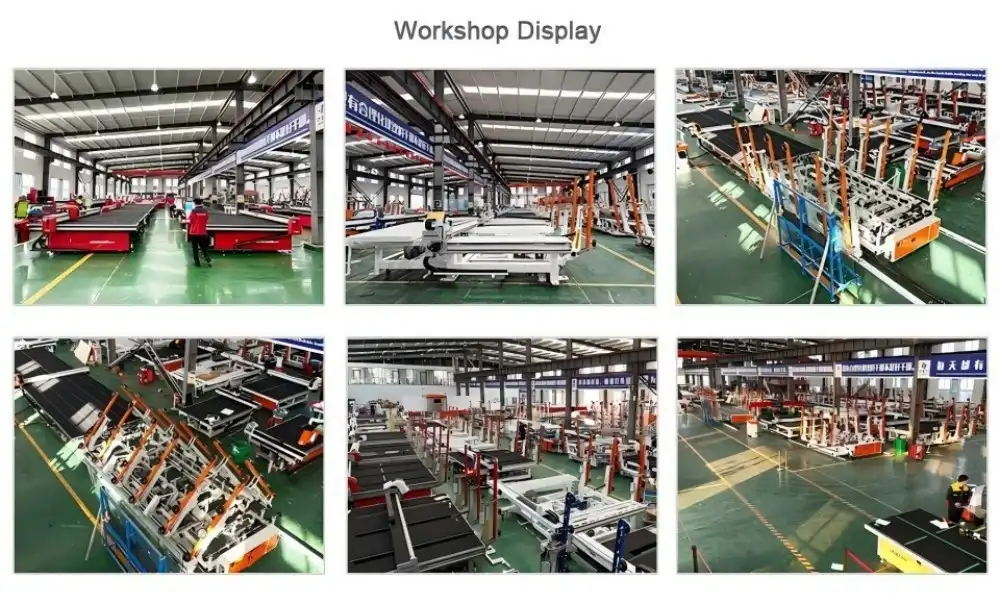

At Shandong Huashil Automation Technology Co., LTD, we understand the importance of proper maintenance for glass cutting machines. Our team of experts is dedicated to providing top-quality equipment and support to meet the diverse needs of our customers in the architectural, automotive, and smart mirror industries. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that our customers from all over the world have come to rely on.

If you're looking for high-performance glass cutting machines or need expert advice on maintaining your equipment, don't hesitate to reach out to us. Our team is ready to assist you in optimizing your glass cutting operations and ensuring the longevity of your machinery. Contact us today at salescathy@sdhuashil.com to learn more about our products and services, and discover how we can help you achieve excellence in glass cutting technology.

References

1. Johnson, A. (2022). "Glass Cutting Machine Maintenance: A Comprehensive Guide." Journal of Industrial Machinery, 45(3), 78-92.

2. Smith, R. & Brown, L. (2021). "Optimizing Glass Cutting Operations: Maintenance Strategies for Improved Efficiency." International Glass Technology Review, 18(2), 112-128.

3. Garcia, M. et al. (2023). "Comparative Analysis of Professional and DIY Maintenance Approaches for Industrial Glass Cutting Machines." Journal of Manufacturing Maintenance, 32(1), 45-61.

4. Thompson, K. (2022). "Troubleshooting Common Issues in Modern Glass Cutting Equipment: A Practical Approach." Glass Processing Technology Quarterly, 29(4), 201-215.