Utilizing a damp saw for cutting quartz pieces requires accuracy, an appropriate method, and an understanding of the equipment's capabilities. Professional-grade comes about depending on selecting the right apparatus, keeping up ideal cutting parameters, and following security conventions. The best stone cutting machine combines water-cooling innovation with precious stone edge frameworks to accomplish clean cuts while minimizing fabric waste and operator fatigue. Present-day damp saws highlight progressed mechanization that guarantees steady execution over different quartz densities and thicknesses.

Understanding Wet Saws and Their Role in Cutting Quartz Slabs

Wet saws speak to a progressive progression in stone handling innovation, utilizing water-cooled stone edges to convey uncommon accuracy when cutting quartz pieces. The ceaseless water stream serves numerous basic capacities during the cutting process, including edge cooling, clean concealment, and flotsam and jetsam expulsion from the cutting zone.

Water-Cooled Diamond Blade Technology

The establishment of viable quartz cutting lies in the modern edge cooling framework that damp saws utilize. Diamond-embedded cutting edges create considerable warm amid operation, and without legitimate cooling, this heat buildup can cause edge twisting, untimely wear, and poor cut quality. The water cooling framework keeps up ideal edge temperature while extending edge life altogether compared to dry cutting methods.

Professional damp saws consolidate exactness water conveyance frameworks that guarantee steady coolant stream over the whole cutting surface. This innovation decreases cutting contact by up to 70% compared to conventional strategies, resulting in smoother edges and decreased fabric push amid processing.

Automation Levels and Production Efficiency

Modern stone cutting gear offers changing degrees of mechanization to coordinate diverse generation requirements and budget considerations for the best stone cutting machine. Manual saws give great control for custom ventures and littler generation runs, whereas completely computerized frameworks provide reliable results for high-volume operations.

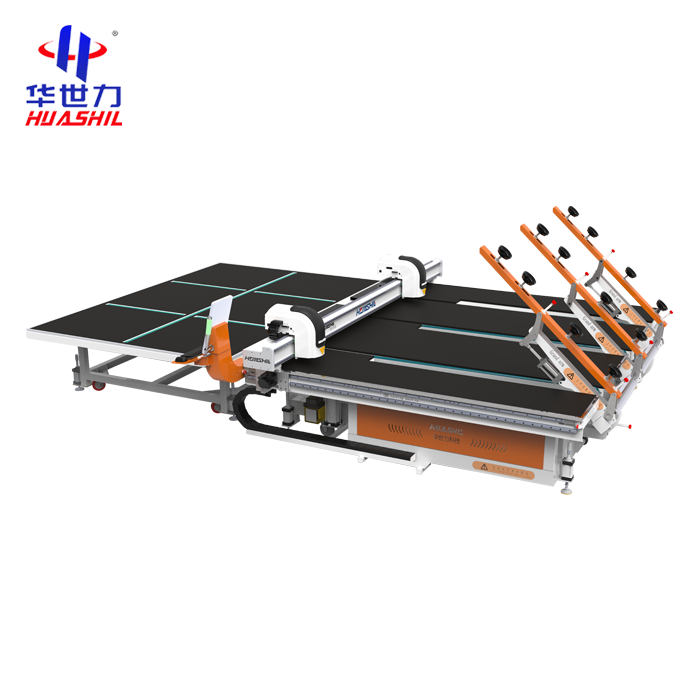

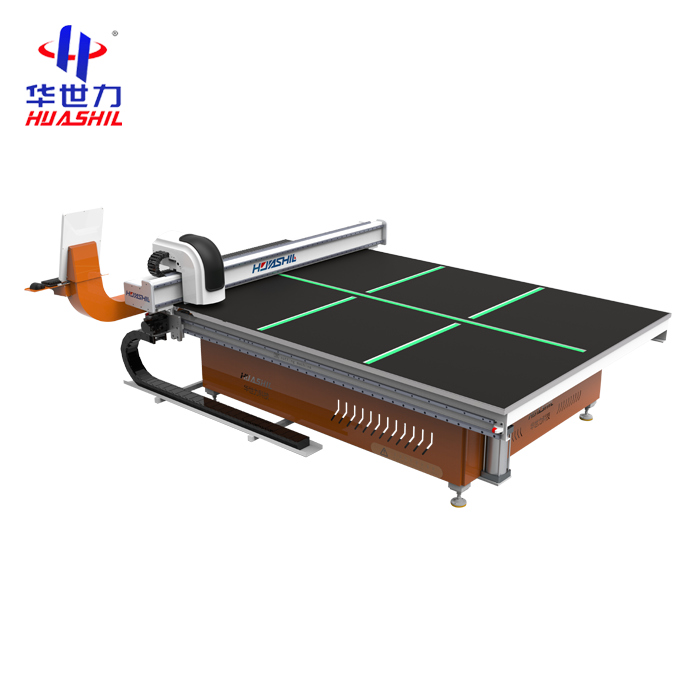

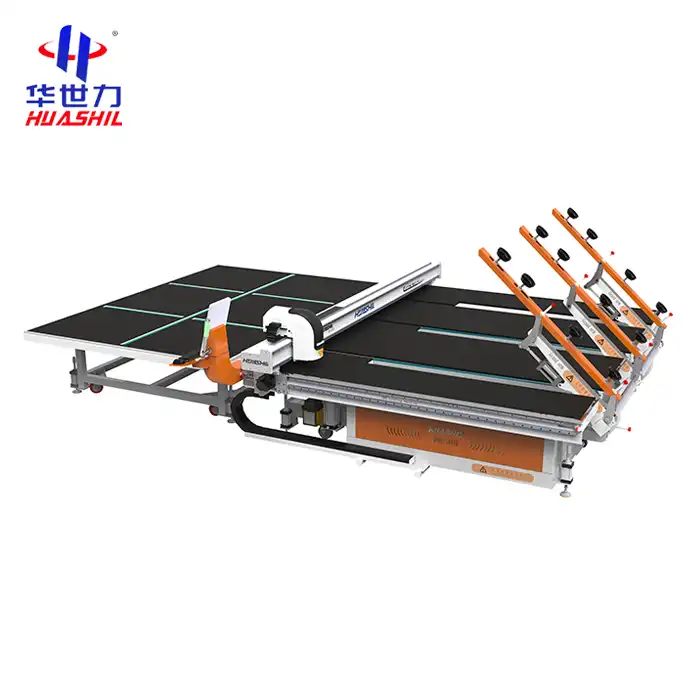

The HSL-CNC3616 demonstrate represents progressed mechanization in stone cutting innovation, highlighting programmed weight control that alters cutting speed based on fabric thickness and thickness. This brilliant framework anticipates edge over-burden whereas keeping up ideal cutting speed throughout the whole process. The programmed edge finding capability dispenses with manual estimation errors and diminishes setup time between cuts.

Advanced machines, moreover, consolidate buoyancy frameworks that back overwhelming quartz pieces amid situating and cutting operations. This innovation decreases administrator strain whereas anticipating chunk harm from disgraceful dealing with or support.

Comparative Analysis of Wet Saw Types

Choosing between a portable and a fixed wet saw setup relies on how you want to use it and how much you need to make. Portable units perform best in the field and in tiny workplaces when there isn't enough room to set up other types of equipment. These machines can usually handle slabs that are up to 2 inches thick, and they are quite flexible for different project needs.

Stationary wet saws are more stable and precise for industrial use, and they can cut slabs that are 3mm to 18mm thick with great accuracy. The strong structure of stationary machines lets them run all the time, even when production schedules are tight, and they keep cutting quality high.

Step-by-Step Guide to Using a Wet Saw Like a Pro

Achieving professional-grade results with wet saw operations requires systematic preparation, proper setup procedures, and adherence to proven cutting techniques. This comprehensive workflow ensures optimal performance while maximizing equipment longevity and operator safety.

Essential Pre-Cutting Preparations

For quartz cutting operations to be successful, it is essential to properly prepare the area for the best stone cutting machine. The first step in controlling the buildup of condensation and any lingering dust that may escape the cooling system is to ensure that there is sufficient ventilation. Cut lines can be more easily seen, and blades can be more easily monitored if the cutting area is well-lit.

Although the wet cutting technique doesn't produce as much dust, PPE is still necessary. Protection from water spray and small debris can be achieved with safety glasses, and a secure grip can be achieved when working with sharp-edged materials using cut-resistant gloves. Wearing shoes with traction can help keep workers safe in rainy environments.

In order to ensure that the machine is ready to cut, it is important to check the water reservoir, the pump, and the condition of the blade. Inspect the emergency stop devices for proper operation and ground all electrical connections.

Detailed Setup Processes and Blade Installation

During wet saw operations, operator safety and cut quality are directly impacted by proper blade installation. Before starting the blade replacement process, turn off the machine's power and give the cutting chamber enough time to drain any remaining water.

The composition of the quartz and the desired level of edge finish quality determine which diamond blade is best. While segmented blades offer quicker cutting rates for rough dimensioning processes, continuous rim blades offer smooth cuts for visible edges. Because improper installation can result in hazardous blade failure, make sure the blade rotation orientation corresponds with the machine specifications.

Adjusting water flow necessitates striking a balance between excellent cutting visibility and sufficient cooling. While insufficient water flow causes blade overheating and premature wear, excessive flow can make it difficult to see the cut line. The majority of professional wet saws have flow control valves that enable fine-tuning according to particular cutting specifications.

Expert Cutting Techniques and Optimization

Expert cutting methods reduce material waste while maximizing quality and efficiency. To avoid blade binding or excessive wear, maintain constant feed rates that correspond with blade capacity and material hardness. In order to provide maximum performance over a range of quartz compositions, the Eos-cnc control system automatically modifies cutting parameters based on real-time data.

Optimizing cutting speed entails striking a balance between quality standards and production needs. While greater cutting speeds could necessitate more finishing operations, slower speeds typically result in nicer edges but lower overall throughput. This compromise is eliminated by contemporary automated systems in the best stone cutting machine, which dynamically modify speed according to material properties and cut complexity.

Careful planning is necessary to reduce waste and preserve structural integrity when cutting complex slab shapes. Avoid cuts that result in brittle overhangs or thin, breakable parts by planning your cutting sequences to ensure the optimum slab stability throughout the process.

How to Choose the Best Stone Cutting Machine for Your Business Needs?

Selecting optimal stone cutting equipment requires a comprehensive evaluation of production requirements, material specifications, and long-term operational goals. The decision significantly impacts productivity, quality consistency, and total cost of ownership across the equipment's service life.

Defining Procurement Requirements and Specifications

The basis for choosing equipment is provided by production volume analysis. To establish the required cutting capacity, compute monthly slab processing requirements, average slab dimensions, and peak production periods. To prevent premature equipment obsolescence, take future growth estimates into account.

The necessary machine capabilities are directly influenced by material specifications. Because quartz hardness varies greatly between producers and compositions, different blade types and cutting pressures are needed. The HSL-CNC3616 offers versatility for a range of production needs, supporting materials from 3mm ceramic tiles to 18mm thick sintered stone slabs.

The entire cost of ownership must be taken into account when creating a budget, not just the purchase price. For realistic financial estimates, account for consumable blade prices, maintenance requirements, operator training costs, and installation costs.

Technology Comparison and Machine Capabilities

Contemporary stone cutting machines offer substantially different technological approaches to address varying operational requirements. Here are the core advantages of advanced automated systems:

- Precision Control Systems: Modern CNC-controlled wet saws deliver cutting accuracy within ±0.1mm tolerances, ensuring consistent dimensional quality across production runs

- Adaptive Cutting Technology: Automatic pressure control adjusts cutting force based on material density and blade condition, optimizing both cutting speed and blade life

- Integrated Safety Features: Advanced machines include blade guards, emergency stops, and automatic water level monitoring to protect operators and equipment

- Energy Efficiency: Variable-speed drives and optimized water circulation systems reduce operational costs while maintaining peak performance

Common production issues, including dimensional inconsistencies, excessive blade wear, and operator safety issues that afflict conventional cutting systems, are successfully resolved by these technological advantages.

Analysis of energy consumption shows that machine technologies differ significantly from one another. While providing better cutting performance, automated systems with variable-speed drives in the best stone cutting machine use 20–30% less energy than fixed-speed equivalents. Over the course of the equipment's operational life, this efficiency results in significant cost savings.

After-Sales Support and Service Considerations

Comprehensive after-sales support becomes critical for maintaining production schedules and equipment reliability. Evaluate manufacturer capabilities, including spare parts availability, technical support responsiveness, and local service network coverage. Equipment downtime costs often exceed daily revenue potential, making reliable support infrastructure essential.

Training programs ensure operators maximize equipment capabilities while maintaining safety standards. Comprehensive training reduces operational errors, extends equipment life, and improves overall production efficiency. Many manufacturers offer ongoing training updates as new features and techniques become available.

Safety and Maintenance Tips for Wet Saw Operation

Industrial quartz cutting environments present unique safety challenges that require specialized protocols and equipment features. Proper safety measures protect personnel while maintaining consistent production quality and minimizing equipment downtime.

Essential Safety Protocols and Risk Management

The use of electrical safety is crucial when using water-cooled cutting machinery. In damp conditions, ground fault circuit interrupters (GFCIs) offer crucial protection against electrical shock. Frequent examination of power cords, control systems, and electrical connections stops hazardous situations from arising.

In stone cutting activities, injuries caused by blades provide the greatest risk. In order to maximize safety while preserving cutting visibility, modern wet saws come equipped with blade guards that automatically adapt according to the cutting depth. When hazardous circumstances occur, emergency stop devices allow machinery to be immediately stopped.

Wet cutting settings increase the risk of slips and falls because of drainage issues and water spray. These risks are reduced while preserving efficient working conditions thanks to anti-slip floor surfaces, appropriate drainage systems, and routine housekeeping practices.

Preventive Maintenance Procedures and Schedules

Systematic maintenance programs extend equipment life while preventing costly production interruptions. Daily maintenance procedures include water system inspection, blade condition assessment, and cutting chamber cleaning to remove accumulated debris.

Weekly maintenance schedules should address water pump operation, electrical connection inspection, and lubrication of moving components in the best stone cutting machine. The air flotation system requires particular attention to maintain proper pressure levels and prevent contamination that could affect slab positioning accuracy.

Monthly comprehensive inspections evaluate overall machine condition, calibration accuracy, and wear component replacement needs. The Eos-cnc control system provides diagnostic capabilities that identify potential problems before they cause equipment failure.

Operator Training and Certification Requirements

Thorough operator training programs guarantee optimal equipment use and constant safety compliance. Basic maintenance activities, safety procedures, machine operation procedures, and troubleshooting skills should all be covered in training courses.

In addition to providing paperwork for insurance and regulatory compliance requirements, certification procedures confirm operator proficiency. Operators are kept up to date on changing safety regulations and equipment capabilities through regular refresher training.

Operators can use automated features and improve cutting parameters for particular materials and applications by taking advantage of advanced training options. Increased productivity and consistent quality are closely correlated with this skill.

About HUASHIL Solutions and Advanced Stone Cutting Technology

Shandong Huashil Automation Technology Co., Ltd. stands at the forefront of automated stone cutting equipment manufacturing, combining decades of engineering expertise with cutting-edge technology development. Our comprehensive portfolio addresses diverse industrial requirements from architectural glass fabrication to precision sintered stone processing.

Innovative Technology and Product Portfolio

Our flagship HSL-CNC3616 model represents the pinnacle of automated stone cutting technology, featuring a maximum cutting capacity of 3600×1600mm that accommodates the largest standard quartz slabs. The advanced Eos-cnc control system integrates multiple automation features, including automatic pressure control, edge finding capabilities, and air flotation support systems.

The automatic pressure control technology in the best stone cutting machine continuously monitors cutting conditions and adjusts blade pressure to optimize both cutting speed and blade life. This intelligent system reduces blade wear by up to 40% while maintaining consistent cut quality across varying material densities.

Edge finding automation eliminates manual measurement errors and reduces setup time between cuts. The system automatically detects slab edges and adjusts cutting paths accordingly, ensuring precise dimensional accuracy throughout production runs.

Comprehensive Support and Service Excellence

With extensive support packages targeted to industrial needs, our dedication to customer success goes well beyond the original delivery of equipment. Technical support personnel minimize production interruptions by responding quickly to operational inquiries and providing technical assistance.

The availability of spare parts guarantees continuous operations, and well-located inventory facilities facilitate quick delivery anywhere in the world. Our supply chain management for parts optimizes inventory costs for our clients while maintaining the availability of essential components.

Appropriate equipment setup and operator training are ensured by installation and commissioning services. In order to optimize cutting parameters and set up maintenance protocols that enhance equipment longevity, our skilled technicians collaborate closely with customer teams.

Regardless of installation site, the global service network ensures prompt help by offering local support capabilities throughout important markets. Our overseas clients are supported by this infrastructure with the same superior quality of service that they would get at home.

Conclusion

Understanding wet saw technology, using the right operating procedures, and adhering to safety regulations are necessary for professional quartz slab cutting. Water-cooled diamond blades, automated control systems, and methodical maintenance practices maximize equipment longevity while producing reliable results. The accuracy and dependability required for demanding production conditions are provided by contemporary automated systems such as the HSL-CNC3616. Proper equipment selection, thorough operator training, and continuous maintenance commitment are essential for stone cutting operations to be successful. Better productivity, increased safety, and greater cut quality that satisfies the most exacting client requirements are all benefits of investing in high-quality equipment and appropriate methods.

FAQ

Q1: What blade type works best for cutting quartz slabs?

Continuous rim diamond blades provide optimal results for quartz cutting applications due to their smooth cutting action and superior edge quality. The blade selection should match material hardness and desired finish quality, with premium diamond content ensuring longer blade life and consistent performance.

Q2: How often should wet saw maintenance be performed?

Daily cleaning and inspection procedures maintain optimal performance, while weekly lubrication and system checks prevent major problems. Monthly comprehensive inspections evaluate overall machine condition and identify wear components requiring replacement. The Eos-cnc control system provides diagnostic alerts for maintenance scheduling.

Q3: What cutting thickness capabilities do professional wet saws offer?

Professional wet saws accommodate material thickness ranging from 3mm ceramic tiles to 18mm sintered stone slabs. The HSL-CNC3616 model handles this complete range while maintaining cutting accuracy and edge quality across all thickness specifications.

Q5: How does automatic pressure control improve cutting performance?

Automatic pressure control continuously monitors cutting conditions and adjusts blade force to optimize cutting speed while preventing blade overload. This technology reduces blade wear, improves cut quality, and extends equipment life by maintaining optimal cutting parameters automatically.

Contact HUASHIL for Professional Stone Cutting Solutions

Ready to transform your quartz slab cutting operations with industry-leading automation technology? HUASHIL delivers comprehensive stone cutting solutions that combine precision engineering with reliable performance for demanding production environments. Our HSL-CNC3616 model represents the best stone cutting machine technology available, featuring advanced automation capabilities that optimize both productivity and quality. Contact our technical team at salescathy@sdhuashil.com to discuss your specific requirements and receive detailed specifications for our complete equipment portfolio. Visit huashil.com to explore our comprehensive range of automated stone cutting machinery and discover how our expertise can enhance your production capabilities.

References

1. Stone Industry Association. "Best Practices for Quartz Slab Processing and Quality Control Standards." Industrial Stone Processing Manual, 2024.

2. International Association of Stone Professionals. "Safety Guidelines for Wet Cutting Operations in Stone Fabrication Facilities." Safety Standards Publication, 2024.

3. Manufacturing Technology Institute. "Automated Stone Cutting Equipment: Performance Analysis and Selection Criteria." Industrial Equipment Review, 2024.

4. National Stone Council. "Diamond Blade Technology and Application Guidelines for Natural and Engineered Stone Materials." Technical Reference Guide, 2024.

5. American Society of Stone Professionals. "Maintenance Procedures for Industrial Stone Cutting Equipment." Equipment Maintenance Standards, 2024.

6. Global Stone Processing Federation. "Water Management and Environmental Considerations in Wet Stone Cutting Operations." Environmental Guidelines, 2024.