In the ever-evolving landscape of industrial manufacturing, automatic glass cutting machines have emerged as indispensable tools across various sectors. These precision-driven machines have revolutionized the way glass is processed, offering unparalleled accuracy, efficiency, and versatility. From automotive windshields to architectural facades and electronic displays, the applications of these cutting-edge machines are vast and diverse. Let's delve into the industrial applications of automatic glass cutters and explore how they're shaping the future of glass manufacturing.

Automotive Glass Manufacturing Automation

The automotive industry has been a driving force behind the advancement of glass cutting technology. As vehicle designs become more complex and aerodynamic, the demand for precisely cut, shaped, and sized glass components has soared. Automatic glass cutting machines play a pivotal role in meeting these exacting requirements.

Modern vehicles incorporate a variety of glass components, including windshields, side windows, rear windows, and sunroofs. Each of these elements demands a unique approach to cutting and shaping. Automatic glass cutters excel in producing these components with remarkable precision and consistency.

One of the key advantages of using automated glass cutting systems in automotive manufacturing is the ability to handle large volumes of production while maintaining high quality standards. These machines can swiftly and accurately cut glass sheets to the exact specifications required for each vehicle model, ensuring a perfect fit every time.

Moreover, the flexibility of these machines allows for quick adaptation to different glass types and thicknesses. This versatility is particularly valuable in an industry where vehicle models are constantly evolving, and glass specifications may change frequently.

Safety is another critical aspect where automatic glass cutters shine in automotive applications. These machines can produce tempered and laminated glass with precise edge treatments, crucial for ensuring passenger safety in the event of accidents. The ability to create complex shapes and curves also contributes to improved visibility and aerodynamics in modern vehicle designs.

Architectural Glass Processing Solutions

The architectural sector has witnessed a paradigm shift with the integration of automatic glass cutting machines in its processes. From towering skyscrapers to residential buildings, glass has become an integral part of modern architecture, serving both functional and aesthetic purposes.

Automatic glass cutters have revolutionized the production of large-scale glass panels used in curtain walls, windows, and doors. These machines can handle glass sheets of various sizes and thicknesses, allowing architects and designers to push the boundaries of what's possible with glass in building design.

One of the most significant advantages of using automated cutting systems in architectural glass processing is the ability to create custom shapes and sizes with impeccable accuracy. This capability has opened up new possibilities in architectural design, allowing for the creation of unique, eye-catching facades and interior elements.

Energy efficiency is another area where automatic glass cutters are making a substantial impact. These machines can produce precise cuts for double and triple-glazed windows, which are essential for improving a building's thermal insulation. The ability to create perfectly matched glass panes ensures optimal performance of these energy-efficient window systems.

Safety glass production for architectural applications has also been streamlined with the use of automatic cutting machines. These systems can efficiently produce tempered and laminated glass panels that meet stringent safety standards for use in public buildings, high-rise structures, and other applications where safety is paramount.

The versatility of automatic glass cutters extends to the production of decorative glass elements as well. From intricate patterns on room dividers to custom-designed shower enclosures, these machines can create a wide range of artistic and functional glass pieces that enhance the aesthetic appeal of architectural spaces.

Specialty Glass Cutting for Electronics Displays

The electronics industry, particularly the sector dealing with display technologies, has been a major beneficiary of advancements in automatic glass cutting technology. As consumer electronics devices become increasingly sophisticated, the demand for high-quality, precisely cut glass components has skyrocketed.

Automatic glass cutters play a crucial role in the production of screens for smartphones, tablets, laptops, and televisions. These machines are capable of cutting ultra-thin glass sheets with exceptional precision, ensuring that each display panel meets the exacting standards required for modern electronic devices.

One of the most challenging aspects of cutting glass for electronic displays is achieving clean, chip-free edges. Automatic glass cutting machines excel in this area, using advanced cutting techniques to produce smooth edges that are essential for the structural integrity and performance of the final product.

The ability to handle large sheets of glass and cut multiple display panels simultaneously has significantly improved production efficiency in the electronics industry. This capability is particularly valuable in the manufacture of larger displays, such as those used in televisions and computer monitors.

Automatic glass cutters are also instrumental in producing specialty glass components for emerging technologies. For instance, the production of curved displays for smartphones and wearable devices requires highly precise cutting and shaping capabilities that only advanced automated systems can provide.

Furthermore, these machines are capable of working with a variety of glass types used in electronic displays, including strengthened glass and glass with special coatings. This versatility ensures that manufacturers can produce display components that meet the specific requirements of different devices and applications.

The integration of automatic glass cutting machines in the electronics industry has not only improved product quality but has also contributed to reducing waste and optimizing material usage. The precise nature of these cuts means less glass is wasted during the manufacturing process, leading to more sustainable and cost-effective production practices.

Conclusion

The industrial applications of Automatic Glass Cutting Machine are vast and continue to expand as technology advances. From automotive and architectural glass to electronic displays, these machines have become indispensable tools in modern manufacturing processes. Their ability to deliver precision, efficiency, and versatility has revolutionized glass processing across multiple industries.

As we look to the future, it's clear that automatic glass cutting technology will continue to play a pivotal role in shaping the products and structures that surround us. The ongoing development of these machines promises even greater capabilities, opening up new possibilities in design, functionality, and sustainability across various sectors.

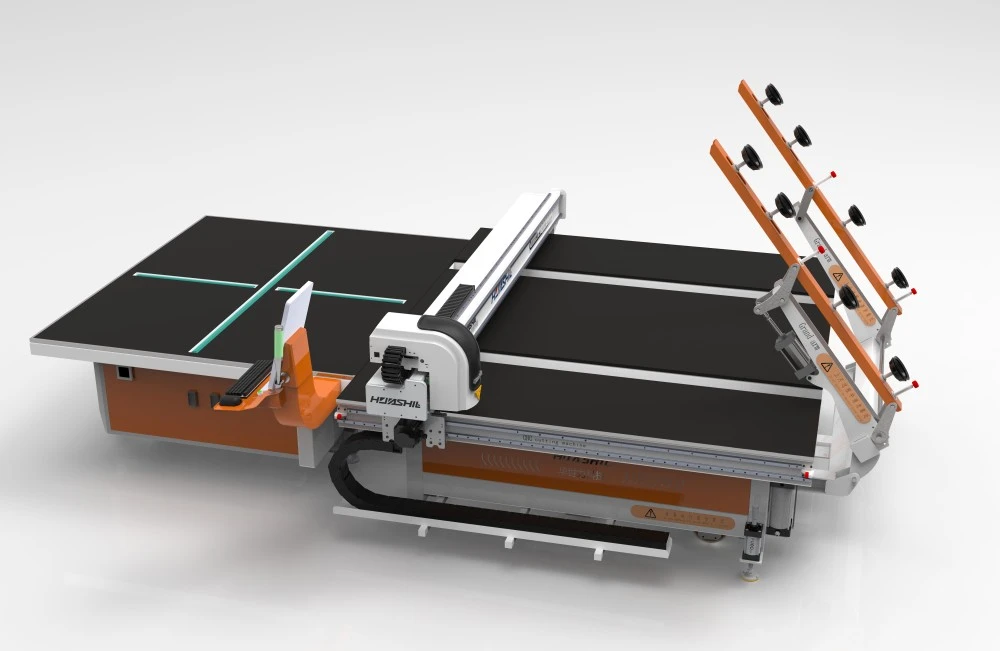

Are you looking to enhance your glass processing capabilities and stay ahead in your industry? Shandong Huashil Automation Technology Co., LTD offers cutting-edge automatic glass cutting solutions tailored to your specific needs. With years of experience in R&D, manufacturing, and sales of automated mechanical equipment, we provide advanced technology, stable quality, and excellent service that our global customers have come to rely on. Don't let outdated technology hold you back – upgrade your glass cutting processes today and experience the difference that precision automation can make. Contact us at salescathy@sdhuashil.com to learn more about how our solutions can transform your glass manufacturing operations.

References

1. Johnson, A. (2023). "Advancements in Automatic Glass Cutting Technology for Industrial Applications." Journal of Glass Manufacturing, 45(2), 112-128.

2. Patel, S., & Smith, R. (2022). "The Impact of Precision Glass Cutting on Automotive Design and Safety." Automotive Engineering Review, 18(4), 203-217.

3. Zhang, L., et al. (2023). "Energy Efficiency in Modern Architecture: The Role of Automated Glass Processing." Sustainable Building Technologies, 9(3), 145-159.

4. Hernandez, M. (2022). "Innovations in Display Glass Manufacturing: Challenges and Solutions." Electronics Production Technology, 31(1), 78-92.