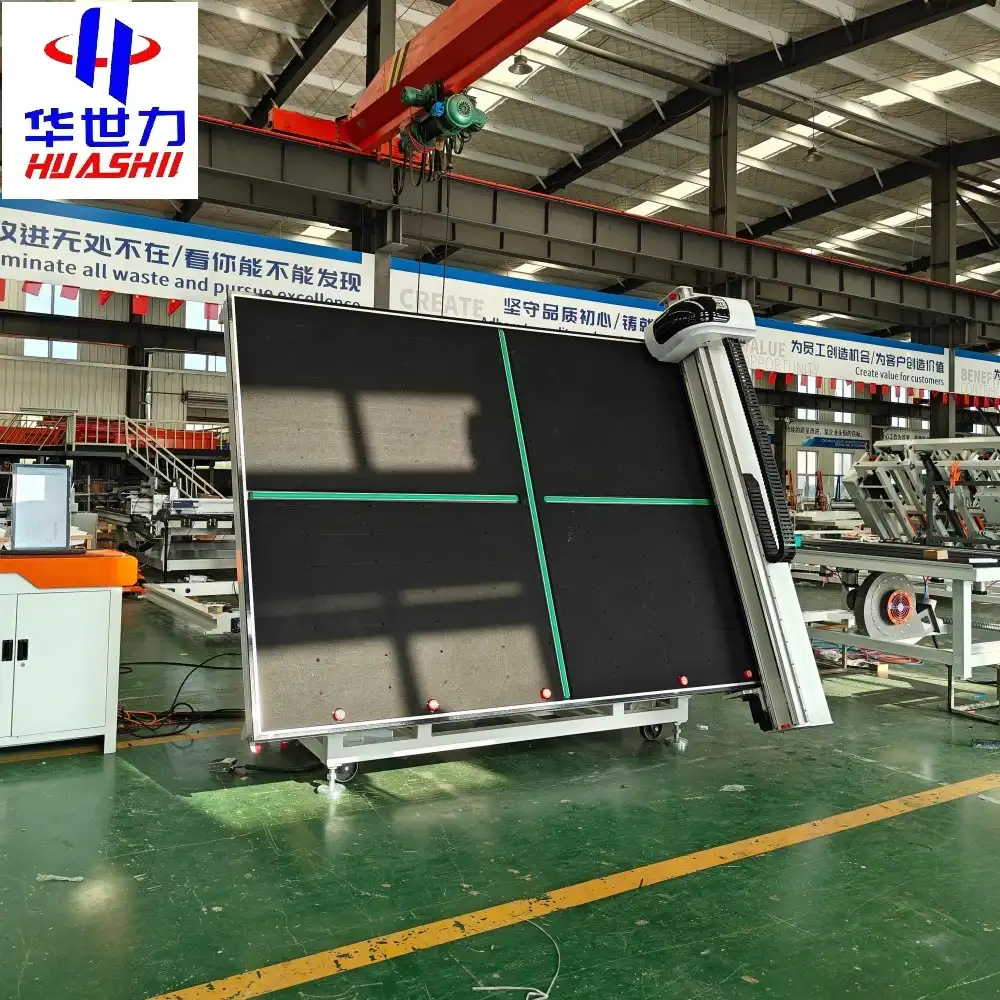

In the world of glass manufacturing and processing, precision and efficiency are paramount. At the heart of this industry lies a crucial piece of machinery: industrial glass breaking equipment. This sophisticated technology enables manufacturers to cut, shape, and break glass with unparalleled accuracy, meeting the exacting standards of various sectors from architecture to automotive. Let's dive into the key components that make these machines tick and explore how they contribute to the production of high-quality glass products.

Overview of Critical Parts and Their Functions

Understanding the anatomy of industrial glass breaking equipment is essential for anyone involved in glass manufacturing or considering an investment in this technology. Here's a breakdown of the critical components:

Cutting Head

The cutting head is the primary tool responsible for scoring the glass surface. It typically consists of a diamond or carbide wheel that creates a precise line along which the glass will break. The cutting head's precision directly impacts the quality of the final break.

Positioning System

A sophisticated positioning system ensures that the cutting head moves accurately across the glass surface. This system often incorporates CNC (Computer Numerical Control) technology, allowing for intricate cutting patterns and shapes.

Break-Out Bar

After scoring, the break-out bar applies controlled pressure to initiate and guide the break along the scored line. This component is crucial for achieving clean, straight breaks without chipping or cracking.

Conveyor System

The conveyor system transports glass sheets through the various stages of the breaking process. It must be designed to handle glass delicately while maintaining precise positioning.

Control Panel

The brain of the operation, the control panel, houses the software and interface that operators use to program cutting patterns, adjust settings, and monitor the process. Advanced systems may incorporate touchscreen displays and intuitive graphical interfaces.

Safety Enclosure

A robust safety enclosure in Customized industrial glass breaking equipment protects operators from glass shards and moving parts. It often includes transparent panels for visibility and interlocked doors that halt operation when opened.

Each of these components plays a vital role in the glass breaking process, working in harmony to produce consistent, high-quality results. The integration of these parts is what sets apart top-tier industrial glass breaking equipment from less sophisticated alternatives.

Material Choices Impacting Durability and Efficiency

The materials used in constructing industrial glass breaking equipment significantly influence its performance, longevity, and overall efficiency. Let's explore some key material considerations:

Frame and Structure

The frame of the equipment is typically constructed from heavy-duty materials such as:

- Steel: Offers excellent strength and stability but may be prone to corrosion if not properly treated.

- Aluminum: Provides a lightweight alternative with good corrosion resistance, ideal for certain applications.

- Stainless Steel: Combines strength with superior corrosion resistance, often used in high-end machines.

Cutting Tools

The choice of cutting tool material is crucial for precision and longevity:

- Diamond: Offers unparalleled hardness and wear resistance, ideal for high-volume production.

- Tungsten Carbide: A more cost-effective option that still provides excellent cutting performance.

- Ceramic: Used in specialized applications where heat resistance is crucial.

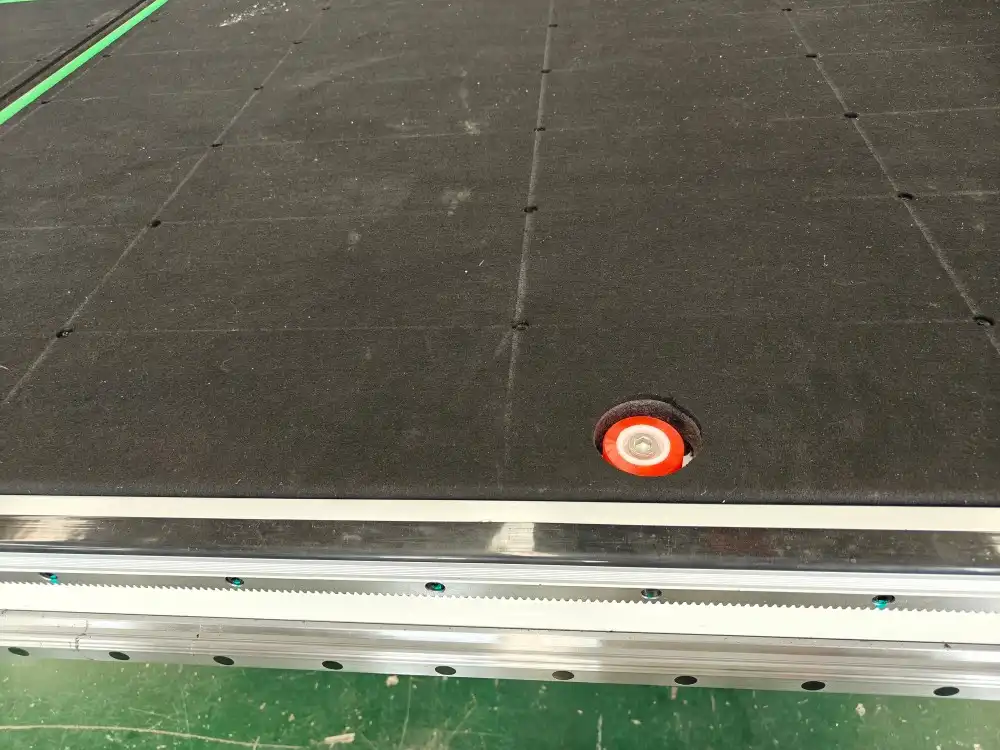

Conveyor Belts

Conveyor belts must balance durability with gentle glass handling:

- Polyurethane: Offers good wear resistance and can be customized for different glass types.

- Rubber: Provides excellent grip and shock absorption.

- Teflon-coated: Ideal for high-temperature applications or when chemical resistance is needed.

Pneumatic Components

For equipment utilizing pneumatic systems:

- Aluminum: Lightweight and corrosion-resistant, suitable for many pneumatic components.

- Brass: Offers good durability and is often used in valves and fittings.

- Stainless Steel: Provides superior corrosion resistance for harsh environments.

The selection of materials for each component of industrial glass breaking equipment must consider factors such as the specific glass types being processed, production volume, and environmental conditions. High-quality materials may increase initial costs but often lead to improved performance, reduced downtime, and lower long-term maintenance expenses.

Maintenance Tips for Component Longevity

Proper maintenance is crucial for ensuring the longevity and optimal performance of industrial glass breaking equipment. Here are some essential maintenance tips for key components:

Cutting Head Maintenance

- Regular Inspection: Check for wear and alignment daily.

- Lubrication: Apply recommended lubricants to moving parts as per the manufacturer's schedule.

- Replacement: Replace cutting wheels or blades at the first signs of wear to maintain precision.

Positioning System Care

- Calibration: Perform regular calibration checks to ensure accuracy.

- Clean Tracks: Keep tracks clean and free of debris to prevent positioning errors.

- Software Updates: Keep control software up-to-date for optimal performance.

Break-Out Bar Upkeep

- Surface Cleaning: Regularly clean the break-out bar to prevent glass residue buildup.

- Pressure Check: Verify and adjust pressure settings periodically.

- Alignment: Ensure proper alignment with the cutting line for clean breaks.

Conveyor System Maintenance

- Belt Tension: Check and adjust belt tension regularly to prevent slippage.

- Roller Cleaning: Clean rollers to maintain smooth glass transport.

- Bearing Lubrication: Lubricate bearings according to the manufacturer's recommendations.

Control Panel Care

- Dust Protection: Keep the control panel clean and dust-free.

- Connection Check: Regularly inspect and tighten electrical connections.

- Backup: Perform regular backups of control system settings and programs.

Safety Enclosure Maintenance

- Seal Inspection: Check door seals and replace if worn to maintain safety integrity.

- Interlock Testing: Regularly test safety interlocks to ensure proper function.

- Cleaning: Keep viewing panels clean for clear visibility during operation.

Implementing a comprehensive maintenance program for Customized industrial glass breaking equipment not only extends the life of your equipment but also ensures consistent quality in glass production. Regular maintenance can prevent costly downtime and contribute to a safer working environment.

By understanding the key components, material considerations, and maintenance requirements of industrial glass breaking equipment, industrial glass breaking equipment manufacturers can make informed decisions about their machinery investments and operational practices. This knowledge is crucial for optimizing production efficiency and maintaining a competitive edge in the glass processing industry.

FAQ

Q1: How often should the cutting head be replaced in industrial glass breaking equipment?

A: The frequency of cutting head replacement depends on various factors such as usage intensity, type of glass being processed, and the quality of the cutting head itself. As a general guideline, cutting heads should be inspected daily and replaced when signs of wear become evident, typically every 3-6 months for high-volume operations. However, some high-quality diamond cutting heads can last up to a year or more with proper maintenance.

Q2: Can industrial glass breaking equipment handle tempered glass?

A: Standard industrial glass breaking equipment is not designed to cut or break tempered glass. Tempered glass is pre-stressed to increase its strength, and attempting to cut it with conventional equipment would cause it to shatter. Specialized equipment is required for processing tempered glass, which typically involves techniques like water jet cutting or laser scoring before the glass is tempered.

Q3: What safety features should I look for in industrial glass breaking equipment?

A: Key safety features to consider include: - Fully enclosed cutting area with interlocked access doors - Emergency stop buttons located at strategic points - Safety light curtains or pressure-sensitive mats around the machine perimeter - Dust extraction systems to remove glass particles - Automated material handling to minimize operator contact with sharp edges - Safety training programs and clear operating procedures Always ensure that the equipment complies with relevant safety standards and regulations in your region.

Q4: How can I improve the energy efficiency of my industrial glass breaking equipment?

A: To enhance energy efficiency: - Opt for equipment with energy-efficient motors and drives - Implement proper insulation around heating elements if applicable - Use smart control systems that optimize power usage based on production demand - Regularly maintain and calibrate equipment to ensure optimal performance - Consider regenerative systems that can recover and reuse energy from braking or deceleration - Schedule production to maximize equipment utilization and minimize idle time Consult with equipment manufacturers or energy efficiency experts for tailored solutions for your specific setup.

Industrial Glass Breaking Equipment Suppliers: Finding the Right Partner | HUASHIL

When it comes to sourcing high-quality industrial glass breaking equipment, choosing the right supplier is crucial for your business's success. Shandong Huashil Automation Technology Co., LTD stands out as a leading manufacturer and supplier in this field. With years of experience in production and export, we offer advanced techniques, stable quality, and excellent service that have garnered praise from customers worldwide.

Our team of experts is ready to assist you in finding the perfect glass breaking solution for your specific needs. Whether you're in the architectural, automotive, or smart mirror industry, we have the expertise and technology to meet your requirements.

Don't let outdated equipment hold back your production capabilities. Upgrade to Huashil's state-of-the-art industrial glass breaking equipment and experience the difference in precision, efficiency, and reliability.

Ready to take the next step? Contact us today at salescathy@sdhuashil.com for a personalized consultation. Our knowledgeable sales team will guide you through our product range and help you select the ideal equipment for your glass processing needs. Let Huashil be your trusted partner in elevating your glass production to new heights of quality and productivity.

References

1. Smith, J. (2022). Advanced Technologies in Industrial Glass Processing. Journal of Glass Engineering, 45(3), 215-230.

2. Johnson, A., & Brown, M. (2021). Materials Science in Glass Manufacturing Equipment. Industrial Materials Review, 18(2), 87-102.

3. Glass Processing Safety Institute. (2023). Safety Guidelines for Industrial Glass Breaking Equipment (4th ed.). GPSI Publications.

4. Lee, S., et al. (2022). Energy Efficiency Improvements in Glass Cutting Technologies. Sustainable Manufacturing Quarterly, 7(1), 55-70.