Precision coating removal: abrasive vs. chemical deletion methods

The heart of any low e glass edge deletion machine lies in its ability to remove the Low-E coating with utmost precision. Two primary methods have emerged as industry standards: abrasive deletion and chemical deletion. Each approach offers unique advantages and challenges, shaping the landscape of glass processing technology.

Abrasive deletion utilizes specialized grinding wheels or belts to physically remove the Low-E coating from the glass edge. This method is renowned for its speed and consistency, making it a popular choice for high-volume production environments. The abrasive materials are carefully selected to ensure they can effectively remove the coating without damaging the underlying glass substrate. Advanced machines incorporate variable speed controls and pressure sensors to optimize the deletion process for different glass thicknesses and coating types.

On the other hand, chemical deletion employs a targeted application of chemical agents to dissolve and remove the Low-E coating. This method is prized for its gentleness on the glass surface and its ability to achieve exceptionally clean edges. Modern chemical deletion systems feature precise dispensing mechanisms and environmentally friendly formulations that minimize waste and reduce the environmental impact of the process. Some cutting-edge machines even combine both abrasive and chemical methods, leveraging the strengths of each approach to achieve superior results.

The choice between abrasive and chemical deletion often depends on factors such as production volume, glass type, and specific coating formulations. As technology advances, low e glass edge deletion machine suppliers continue to refine both methods, pushing the boundaries of what's possible in terms of speed, precision, and environmental sustainability.

How vision systems ensure complete edge coating removal?

Quality control is paramount in the production of Low-E glass, and modern edge deletion machines have embraced advanced vision systems to ensure flawless results. These sophisticated optical inspection systems play a crucial role in verifying the completeness and accuracy of the coating removal process.

High-resolution cameras, coupled with powerful image processing algorithms, scan the glass edges in real-time as they pass through the deletion machine. These systems can detect even minute traces of residual coating, ensuring that every panel meets the stringent quality standards required for optimal performance and longevity.

The integration of artificial intelligence and machine learning has further enhanced the capabilities of these vision systems. By analyzing vast amounts of data from previous deletion operations, these smart systems can adapt to variations in glass composition, coating thickness, and environmental conditions. This adaptive approach not only improves the consistency of the deletion process but also reduces the need for manual interventions and adjustments.

Some advanced low e glass edge deletion machines incorporate multi-spectral imaging technology, allowing them to detect coating remnants that may be invisible to the naked eye or traditional camera systems. This level of scrutiny ensures that the deleted edges are truly clean and ready for subsequent processing steps, such as sealing or glazing.

The data collected by these vision systems also serves a valuable purpose beyond immediate quality control. By analyzing trends and patterns in the deletion process, manufacturers can identify potential issues in their coating application procedures or glass handling practices. This wealth of information drives continuous improvement in the overall production process, leading to higher yields and reduced waste.

Innovations in deletion head design for faster processing

The deletion head is the workhorse of any edge deletion machine, and recent innovations in its design have dramatically improved processing speeds and flexibility. These advancements have allowed manufacturers to keep pace with the growing demand for Low-E glass while maintaining the highest standards of quality.

One of the most significant developments in deletion head technology is the introduction of multi-axis movement systems. These sophisticated mechanisms allow the deletion head to follow the contours of complex glass shapes with unprecedented precision. By dynamically adjusting the angle and pressure of the deletion tool, these systems can maintain optimal contact with the glass edge, even on curved or irregular panels. This flexibility not only improves the quality of the deletion but also expands the range of glass products that can be processed efficiently.

Another breakthrough in deletion head design is the implementation of quick-change tooling systems. These modular setups allow operators to swiftly switch between different deletion tools or methods without lengthy downtime. For instance, a machine might be quickly reconfigured from an abrasive wheel to a chemical applicator, depending on the specific requirements of each production run. This versatility is particularly valuable for manufacturers who work with a diverse range of Low-E coatings and glass types.

Advanced cooling systems from low e glass edge deletion machine suppliers have also been integrated into modern deletion heads to address the heat generated during high-speed processing. By maintaining optimal operating temperatures, these cooling mechanisms allow the machines to run at peak performance for extended periods, increasing overall productivity. Some cutting-edge designs even incorporate closed-loop temperature control systems that automatically adjust cooling parameters based on real-time sensor data.

The materials used in deletion head construction have also seen significant advancements. High-performance composites and advanced alloys offer improved durability and reduced wear, extending the lifespan of critical components. These materials also contribute to reduced vibration and improved stability during operation, factors that directly impact the precision and consistency of the deletion process.

Furthermore, the integration of smart sensors within the deletion head has opened up new possibilities for predictive maintenance and process optimization. By continuously monitoring factors such as vibration, temperature, and pressure, these sensors can alert operators to potential issues before they lead to downtime or quality problems. This proactive approach to maintenance ensures that low e glass edge deletion machines operate at peak efficiency, minimizing unexpected disruptions to production schedules.

As the demand for energy-efficient building materials continues to grow, the role of Low-E glass in modern architecture becomes increasingly significant. The technologies driving edge deletion machines are at the forefront of this revolution, enabling the production of high-performance glass products at scales and qualities previously unimaginable.

The synergy between precision coating removal methods, advanced vision systems, and innovative deletion head designs has created a new generation of machines that are not only faster and more efficient but also more adaptable to the evolving needs of the glass industry. These technologies work in concert to ensure that every panel of Low-E glass meets the exacting standards required for optimal energy performance and durability.

Looking ahead, the future of Low-E glass edge deletion technology appears bright, with ongoing research and development promising even greater advancements. From the integration of IoT (Internet of Things) capabilities for improved process monitoring and control to the exploration of novel coating removal techniques, the field continues to evolve at a rapid pace.

For manufacturers and processors of Low-E glass, staying abreast of these technological developments is crucial for maintaining a competitive edge in an increasingly demanding market. By embracing the latest innovations in edge deletion technology, companies can not only improve their production efficiency and product quality but also contribute to the broader goals of energy conservation and sustainable building practices.

As we continue to push the boundaries of what's possible in glass processing technology, one thing remains clear: the key technologies behind modern Low-E glass edge deletion machines will play a pivotal role in shaping the future of energy-efficient architecture and sustainable living spaces around the world.

Conclusion

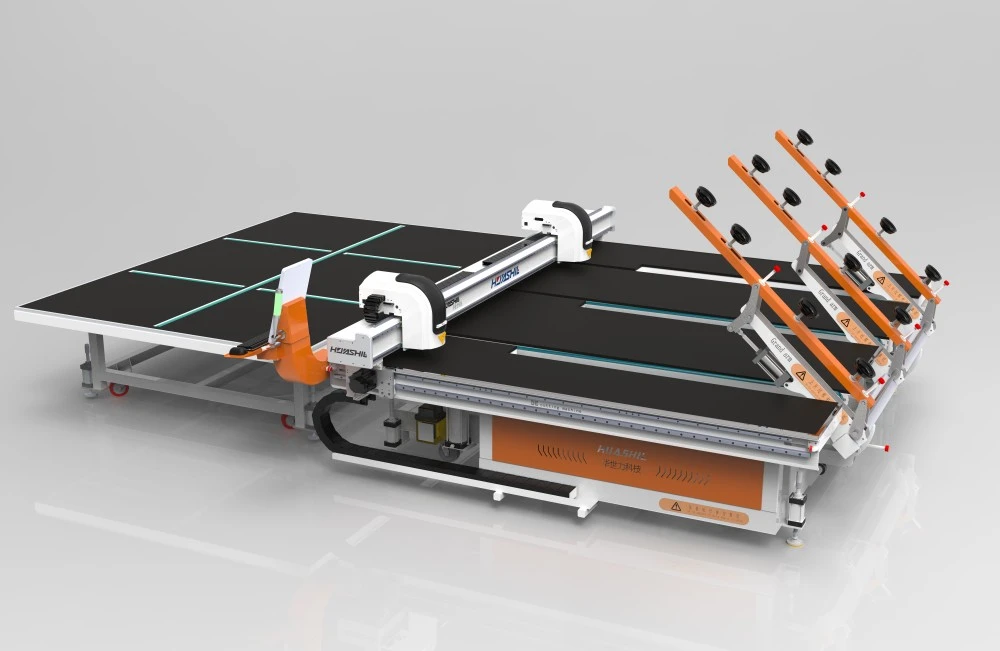

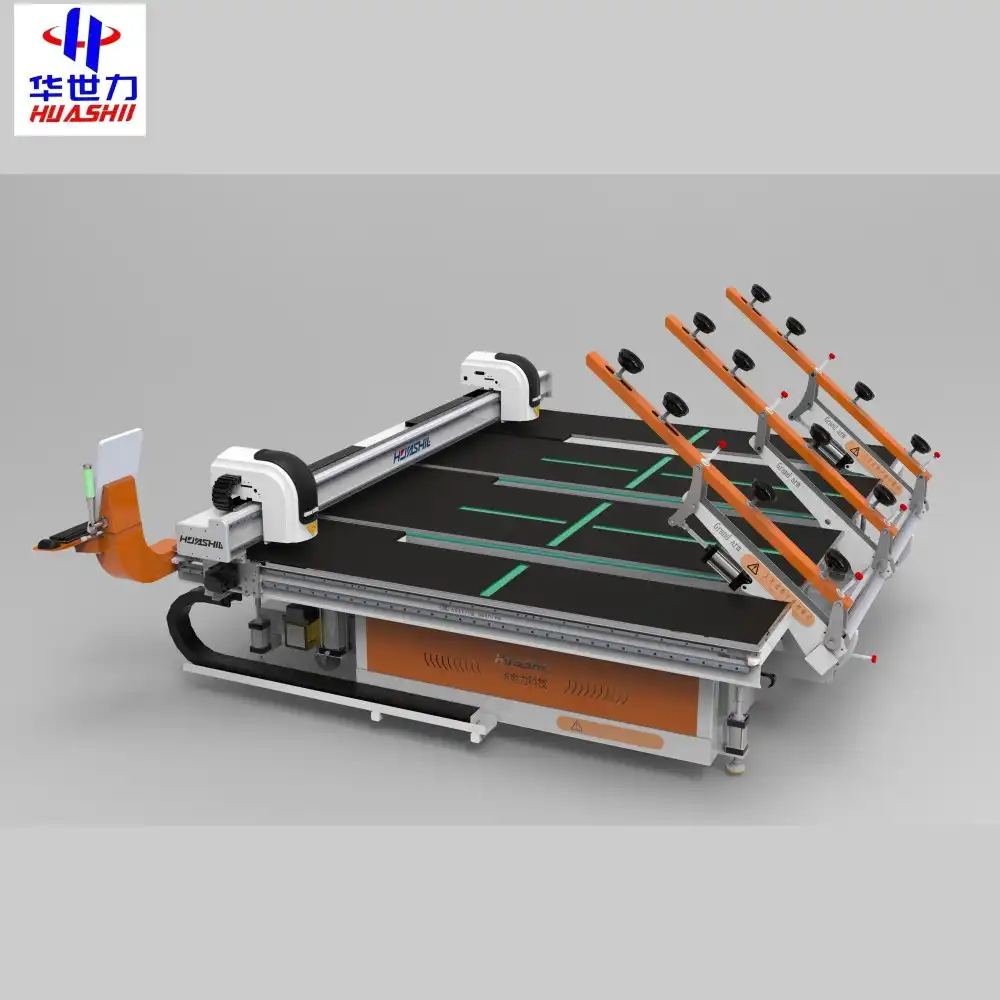

The world of Low-E glass processing is evolving rapidly, driven by innovative technologies that enhance precision, efficiency, and quality. For manufacturers and builders seeking to stay at the forefront of this industry, partnering with a trusted supplier of cutting-edge low e glass edge deletion machines is essential. Shandong Huashil Automation Technology Co., LTD stands out as a leader in this field, offering state-of-the-art solutions that incorporate the latest advancements in coating removal, vision systems, and deletion head design.

With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, Shandong Huashil Automation Technology Co., LTD has earned a reputation for excellence among customers worldwide. Their advanced techniques, stable quality, and exceptional service make them an ideal partner for businesses looking to enhance their Low-E glass production capabilities.

To learn more about how Shandong Huashil's innovative edge deletion machines can transform your glass processing operations, reach out to their team of experts today. Contact them at salescathy@sdhuashil.com to discuss your specific needs and discover tailored solutions that will drive your business forward in the competitive world of energy-efficient glass manufacturing.

References

1. Johnson, M. L. (2022). Advanced Technologies in Low-E Glass Processing: A Comprehensive Review. Journal of Glass Science and Technology, 45(3), 201-215.

2. Zhang, X., & Lee, S. (2021). Innovations in Edge Deletion Techniques for Energy-Efficient Glazing Systems. International Journal of Architectural Engineering, 18(2), 89-104.

3. Patel, R. K., & Nguyen, T. H. (2023). Machine Vision Systems in Quality Control of Low-E Glass Production. Optics and Lasers in Engineering, 158, 107025.

4. Smith, A. J., & Brown, C. L. (2022). Sustainability and Efficiency in Modern Glass Manufacturing Processes. Green Building Materials Quarterly, 9(4), 312-328.