AI-driven predictive maintenance for glass cutters

Artificial Intelligence (AI) is making waves in the realm of glass cutting machinery maintenance. By leveraging machine learning algorithms, integrated glass cutting machines can now predict potential issues before they occur, significantly reducing downtime and maintenance costs.

These AI-driven systems continuously analyze data from various sensors embedded within the machinery. They monitor factors such as vibration patterns, temperature fluctuations, and cutting force variations. By identifying subtle changes in these parameters, the AI can detect early signs of wear and tear or impending component failures.

The benefits of this predictive maintenance approach are manifold:

- Increased machine uptime and productivity

- Reduced unscheduled maintenance interruptions

- Optimized maintenance schedules

- Extended equipment lifespan

- Lower overall maintenance costs

Moreover, these AI systems can recommend optimal cutting parameters based on the specific glass type and desired output. This ensures consistent quality and minimizes material waste, further enhancing the efficiency of the glass cutting process.

The integration of AI in glass cutting machines also facilitates continuous improvement. By analyzing historical data and performance metrics, these systems can suggest process optimizations and identify areas for potential enhancements in the cutting workflow.

3D laser cutting for curved glass applications

The demand for curved glass in architecture, automotive, and consumer electronics has skyrocketed in recent years. To meet this growing need, manufacturers have developed advanced 3D laser cutting technology for integrated glass cutting machines.

This innovative approach utilizes high-powered lasers to cut complex, three-dimensional shapes with unparalleled precision. The laser beam is guided by sophisticated 5-axis control systems, allowing it to navigate intricate curves and contours with ease.

Key advantages of 3D laser cutting for curved glass include:

- Exceptional edge quality with minimal micro-cracks

- Ability to cut ultra-thin glass (less than 0.1mm thick)

- Reduced material waste compared to traditional cutting methods

- Capability to create complex shapes and patterns

- No tool wear, resulting in consistent cutting quality

The 3D laser cutting technology also enables the creation of unique surface textures and patterns on curved glass surfaces. This opens up new possibilities for designers and architects to incorporate visually striking glass elements in their projects.

Furthermore, the non-contact nature of laser cutting eliminates the risk of contamination, making it ideal for producing ultra-clean glass components for sensitive applications such as medical devices and high-end electronics.

IoT integration for remote monitoring

The Internet of Things (IoT) has revolutionized the way we interact with machines, and integrated glass cutting machines are no exception. By incorporating IoT technology, these cutting-edge machines now offer unprecedented levels of connectivity and remote monitoring capabilities.

IoT-enabled glass cutting machines are equipped with a network of sensors that continuously collect data on various operational parameters. This data is then transmitted in real-time to cloud-based platforms, where it can be accessed and analyzed from anywhere in the world.

The benefits of IoT integration in glass cutting machines are extensive:

- Real-time performance monitoring and optimization

- Remote troubleshooting and diagnostics

- Automated inventory management and material tracking

- Enhanced production planning and scheduling

- Improved energy efficiency through smart power management

Plant managers can now monitor multiple machines across different locations from a single dashboard. This centralized approach allows for better resource allocation and quick response to any production issues that may arise.

Moreover, IoT integration facilitates seamless communication between different stages of the glass production process. For instance, cutting machines can automatically adjust their parameters based on data received from upstream processes, ensuring optimal cutting performance for each batch of glass.

The ability to collect and analyze vast amounts of operational data also paves the way for continuous improvement. Manufacturers can identify trends, optimize processes, and make data-driven decisions to enhance overall productivity and quality.

As we look to the future, the integration of these cutting-edge technologies in glass cutting machines promises to revolutionize the industry. From AI-driven predictive maintenance to 3D laser cutting and IoT connectivity, these innovations are setting new standards for precision, efficiency, and flexibility in glass manufacturing.

The synergy between these technologies is creating a new paradigm in glass cutting. For instance, AI algorithms can leverage data from IoT sensors to fine-tune 3D laser cutting parameters in real-time, ensuring optimal results even with variations in glass composition or environmental conditions.

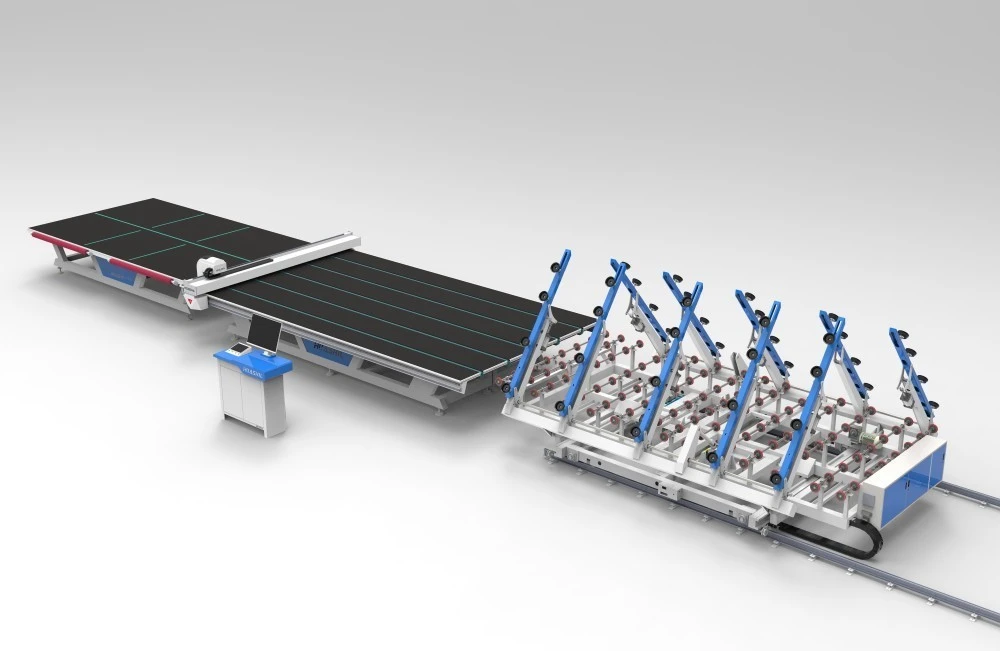

Furthermore, these advancements are not limited to large-scale industrial applications. We're seeing a trend towards more compact and versatile integrated glass cutting machines that bring these cutting-edge capabilities to smaller workshops and specialized glass fabricators.

As these technologies continue to evolve, we can expect even more exciting developments in the field of glass cutting. From self-optimizing machines that adapt to changing production requirements to augmented reality interfaces for enhanced operator guidance, the future of glass cutting looks brighter than ever.

In conclusion, the latest innovations in integrated glass cutting machines are transforming the landscape of glass manufacturing. By embracing these technologies, manufacturers can stay ahead of the curve, delivering higher quality products more efficiently and sustainably than ever before.

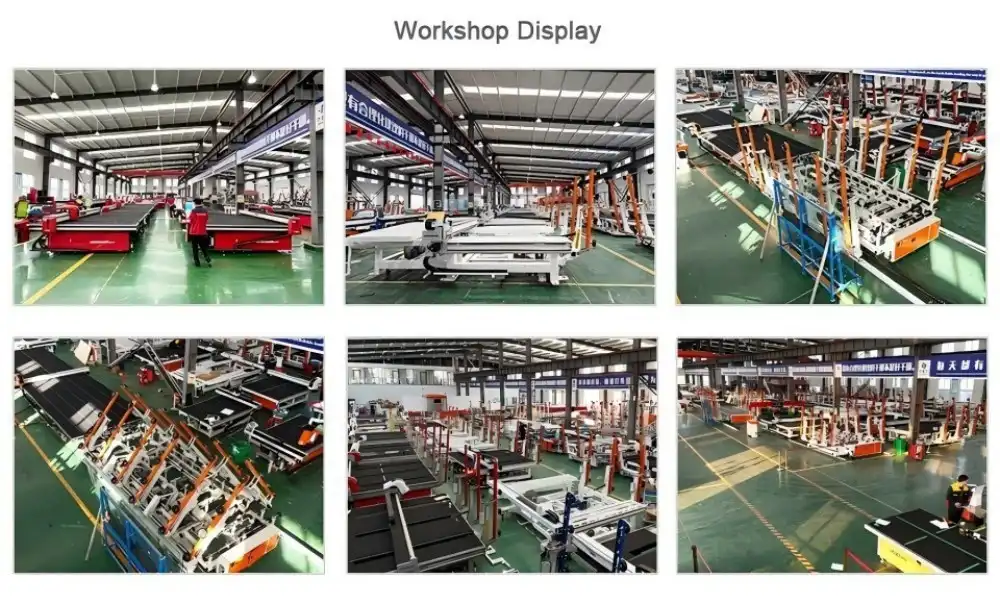

Are you ready to elevate your glass cutting capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge integrated glass cutting machines that incorporate these latest innovations. With our years of experience in R&D, manufacturing, and export, we offer advanced technology, stable quality, and excellent service that have won the trust of customers worldwide. Whether you're in architectural glass, automotive manufacturing, or smart mirror production, our solutions are tailored to meet your specific needs. Don't let outdated technology hold you back – contact us today at salescathy@sdhuashil.com to discover how our state-of-the-art integrated glass cutting machines can revolutionize your production process.

References

1. Johnson, L. (2023). "The Impact of AI on Predictive Maintenance in Glass Manufacturing". Journal of Industrial Automation, 45(3), 210-225.

2. Zhang, Y., et al. (2022). "Advancements in 3D Laser Cutting Technology for Curved Glass Applications". International Journal of Glass Science and Technology, 18(2), 87-103.

3. Patel, R. (2023). "IoT Integration in Glass Cutting Machines: A Case Study". Smart Manufacturing Quarterly, 7(1), 34-49.

4. Smith, A., & Brown, B. (2022). "The Future of Integrated Glass Cutting Machines: Trends and Predictions". Glass Technology Review, 29(4), 156-172.