PLC tasks vs CNC path control explained

While both PLCs and CNC systems are integral to the operation of automatic glass cutting lines, they serve distinct purposes in the overall manufacturing process. Let's elucidate the key differences between PLC tasks and CNC path control:

PLC Tasks

Programmable Logic Controllers (PLCs) act as the central nervous system of the automatic glass cutting line. They are responsible for overseeing and coordinating various aspects of the production process, including:

- Sequence control: PLCs manage the sequential operations of the cutting line, ensuring that each step is executed in the correct order and at the appropriate time.

- Safety monitoring: They continuously monitor safety systems, initiating emergency stops or shutdowns if any anomalies are detected.

- Process parameter management: PLCs regulate and adjust crucial parameters such as cutting speed, pressure, and temperature to maintain optimal cutting conditions.

- Input/output handling: They process inputs from sensors and switches, and control outputs to actuators, valves, and other mechanical components.

- Data logging and reporting: PLCs collect and store production data, generating reports for quality control and process optimization.

In essence, PLCs handle the overall logic and coordination of the automatic glass cutting line for low-e glass, ensuring smooth operation and integration of various subsystems.

CNC Path Control

Computer Numerical Control (CNC) systems, on the other hand, focus specifically on controlling the precise movements and cutting paths of the glass cutting tools. Their primary functions include:

- Motion control: CNC systems calculate and execute complex cutting paths with high precision, often working in multiple axes simultaneously.

- Tool management: They control the selection, positioning, and operation of cutting tools, ensuring optimal performance for different glass types and thicknesses.

- Cutting optimization: CNC systems optimize cutting patterns to maximize material utilization and minimize waste.

- Compensation algorithms: They implement advanced algorithms to compensate for tool wear, material variations, and environmental factors, maintaining cutting accuracy over time.

- G-code interpretation: CNC systems interpret standardized G-code instructions, translating them into precise machine movements.

The CNC system's role is crucial in achieving the high level of precision required for cutting low-e glass, as even minor deviations can compromise the glass's performance and aesthetic qualities.

Synergy between PLC and CNC

While PLC and CNC systems have distinct roles, their seamless integration is vital for the optimal performance of an automatic glass cutting line. The PLC often acts as the master controller, coordinating overall line operations and communicating with the CNC system to synchronize cutting operations with other processes such as glass loading, positioning, and offloading.

This symbiotic relationship allows for real-time adjustments and optimizations, ensuring that the cutting process adapts to variations in glass quality, environmental conditions, and production requirements. The result is a highly flexible and efficient production line capable of handling the demanding specifications of low-e glass manufacturing.

What diagnostics and telemetry are available?

Advanced diagnostics and telemetry capabilities are essential components of modern automatic glass cutting lines, particularly when dealing with the precise requirements of low-e glass production. These features provide invaluable insights into the performance, maintenance needs, and overall health of the cutting line. Let's explore the various diagnostic and telemetry options available in state-of-the-art systems:

Real-time Performance Monitoring

Cutting-edge automatic glass cutting lines incorporate sophisticated sensors and monitoring systems that provide real-time data on various performance metrics:

- Cutting speed and accuracy: Continuous monitoring of cutting tool speed and position ensures adherence to specified tolerances.

- Pressure and force measurements: Sensors track the pressure applied during cutting, crucial for maintaining the integrity of low-e coatings.

- Temperature monitoring: Thermal sensors monitor critical components to prevent overheating and ensure optimal cutting conditions.

- Vibration analysis: Advanced vibration sensors detect abnormal machine vibrations that could affect cutting quality.

This real-time data allows operators to identify and address performance issues promptly, minimizing downtime and maintaining product quality.

Predictive Maintenance

Modern diagnostic systems employ machine learning algorithms and historical data analysis to predict maintenance needs before failures occur:

- Component wear prediction: The system analyzes usage patterns and performance data to forecast when cutting tools or other components may need replacement.

- Anomaly detection: Advanced algorithms identify unusual patterns or behaviors that may indicate impending equipment failures.

- Maintenance scheduling: Based on predictive analysis, the system can suggest optimal maintenance schedules, reducing unnecessary downtime.

Predictive maintenance capabilities significantly reduce unplanned downtime and extend the lifespan of critical components in the automatic glass cutting line.

Quality Assurance Telemetry

To ensure consistent quality in low-e glass cutting, advanced telemetry systems provide comprehensive quality assurance data:

- Dimensional accuracy tracking: High-precision sensors continuously measure cut glass dimensions, flagging any deviations from specifications.

- Edge quality analysis: Optical inspection systems assess the quality of cut edges, crucial for the structural integrity of low-e glass.

- Coating integrity verification: Specialized sensors monitor the condition of low-e coatings during and after cutting to ensure they remain undamaged.

- Defect detection: Advanced image processing algorithms identify and categorize defects in real-time, allowing for immediate corrective action.

This comprehensive quality assurance telemetry ensures that every piece of low-e glass meets the stringent standards required for energy-efficient applications.

Remote Monitoring and Support

Modern automatic glass cutting lines often feature remote monitoring capabilities, allowing for off-site diagnostics and support:

- Secure remote access: Authorized technicians can remotely access the system for diagnostics and troubleshooting, reducing response times.

- Cloud-based data analytics: Production data is securely transmitted to cloud servers for in-depth analysis and long-term performance tracking.

- Mobile alerts: Critical notifications and alerts can be sent to operators' mobile devices, ensuring prompt response to any issues.

- Augmented reality support: Some advanced systems incorporate AR technology for remote guided maintenance and repairs.

These remote capabilities enhance the overall reliability and efficiency of the automatic glass cutting line, minimizing downtime and optimizing performance.

Energy Consumption Analysis

With increasing focus on sustainability, modern diagnostic systems also provide detailed energy consumption data:

- Power usage monitoring: Real-time tracking of energy consumption across different components of the cutting line.

- Efficiency optimization: Analysis of energy usage patterns to identify opportunities for improved efficiency.

- Carbon footprint reporting: Generation of reports on the carbon footprint of the cutting process, aiding in sustainability initiatives.

This energy-focused telemetry helps manufacturers optimize their operations for both cost savings and environmental responsibility.

The comprehensive diagnostics and telemetry available in modern automatic glass cutting lines for low-e glass provide manufacturers with unprecedented insights into their production processes. By leveraging this wealth of data, operators can ensure consistent quality, minimize downtime, and continuously optimize their cutting operations to meet the exacting standards of low-e glass production.

Communication: OPC/UA, Ethernet/IP and SCADA links

Effective communication between various components of an automatic glass cutting line is paramount for seamless operation, especially when dealing with the precision required for low-e glass production. Modern systems employ a variety of communication protocols and interfaces to ensure robust data exchange and system integration. Let's explore the key communication technologies used in advanced automatic glass cutting lines:

OPC UA (Unified Architecture)

OPC UA has emerged as a leading industrial communication standard, offering several advantages for automatic glass cutting lines:

- Platform independence: OPC UA operates across different operating systems and hardware platforms, facilitating easy integration of diverse equipment.

- Scalability: It supports systems ranging from embedded devices to enterprise-level servers, making it suitable for both small-scale and large-scale glass cutting operations.

- Enhanced security: OPC UA incorporates robust security features, including encryption and authentication, crucial for protecting sensitive production data.

- Semantic data modeling: It allows for complex data structures and relationships, enabling more sophisticated control and analysis of the cutting process.

- Future-proofing: As an evolving standard, OPC UA ensures that communication systems remain compatible with future technological advancements.

In automatic glass cutting lines, OPC UA facilitates seamless communication between PLCs, CNCs, and higher-level systems, enabling real-time data exchange and control.

Ethernet/IP

Ethernet/IP (Ethernet Industrial Protocol) is another widely adopted communication standard in industrial automation, offering several benefits for glass cutting lines:

- Deterministic performance: Ethernet/IP provides predictable communication timing, crucial for synchronizing various components of the cutting line.

- High-speed data transfer: It supports rapid exchange of large data volumes, essential for real-time control and monitoring of cutting operations.

- Compatibility: Ethernet/IP is compatible with standard Ethernet hardware, reducing implementation costs and simplifying network architecture.

- Flexible topology: It supports various network topologies, allowing for adaptable system designs to suit different glass cutting line configurations.

- Integration with IT systems: Ethernet/IP facilitates easy integration with broader IT infrastructure, enabling seamless data flow from the shop floor to management systems.

Ethernet/IP is particularly useful in automatic glass cutting lines for coordinating high-speed movements between CNC systems and other motion control devices.

SCADA (Supervisory Control and Data Acquisition) Links

SCADA systems play a crucial role in overseeing and managing the entire glass cutting operation. Key aspects of SCADA communication in automatic glass cutting lines include:

- Centralized monitoring: SCADA systems aggregate data from various sources across the cutting line, providing a comprehensive overview of the entire process.

- Historical data logging: They store long-term production data, enabling trend analysis and performance optimization over time.

- Alarm management: SCADA systems handle alarm generation, prioritization, and notification, ensuring prompt response to critical issues.

- Human-Machine Interface (HMI): They provide intuitive graphical interfaces for operators to monitor and control the cutting line.

- Report generation: SCADA systems can automatically generate production reports, quality analyses, and other key documentation.

SCADA links in automatic glass cutting lines often utilize OPC UA or Ethernet/IP for communication with lower-level devices, while also offering interfaces for integration with higher-level enterprise systems.

Integration and Interoperability

The true power of these communication technologies lies in their integration and interoperability:

- Multi-protocol support: Advanced communication gateways in automatic glass cutting lines often support multiple protocols, allowing seamless integration of legacy and modern equipment.

- Data harmonization: Communication systems harmonize data from diverse sources, ensuring consistent information across different subsystems of the cutting line.

- Real-time synchronization: The combination of these technologies enables real-time synchronization between PLCs, CNCs, and SCADA systems, crucial for maintaining cutting precision in low-e glass production.

- Vertical integration: These communication standards facilitate vertical integration from the shop floor to enterprise-level systems, enabling comprehensive production visibility and control.

By leveraging these advanced communication technologies, manufacturers can create highly integrated and efficient automatic glass cutting lines capable of meeting the exacting standards of low-e glass production. The seamless flow of information between various components ensures optimal performance, rapid response to changing conditions, and comprehensive process control.

Conclusion

The intricate interplay of PLC and CNC systems, advanced diagnostics and telemetry, and robust communication protocols forms the technological backbone of modern automatic glass cutting lines for low-e glass. These sophisticated systems work in harmony to ensure precision, efficiency, and reliability in the production of high-quality low-emissivity glass.

As the demand for energy-efficient building materials continues to grow, the role of these advanced technologies in glass cutting lines becomes increasingly crucial. Manufacturers who leverage these innovations can stay ahead in a competitive market, offering superior products while optimizing their production processes.

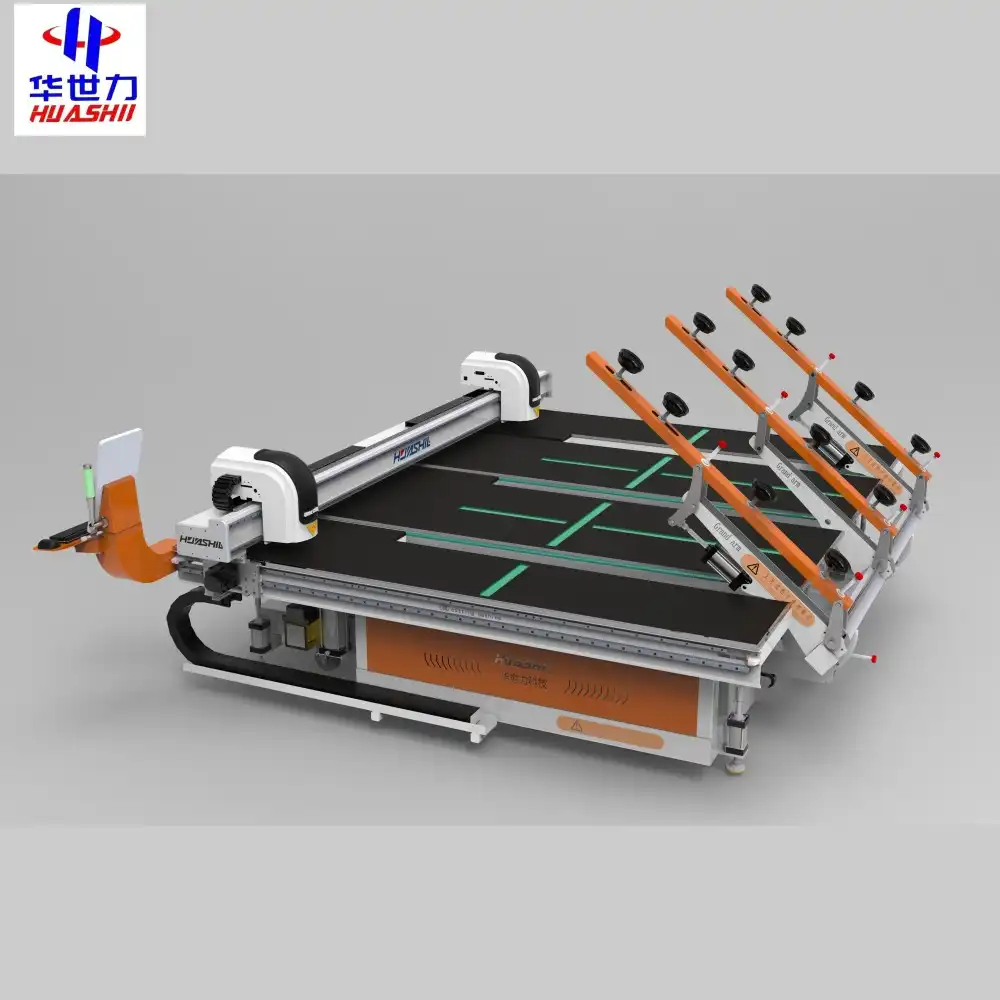

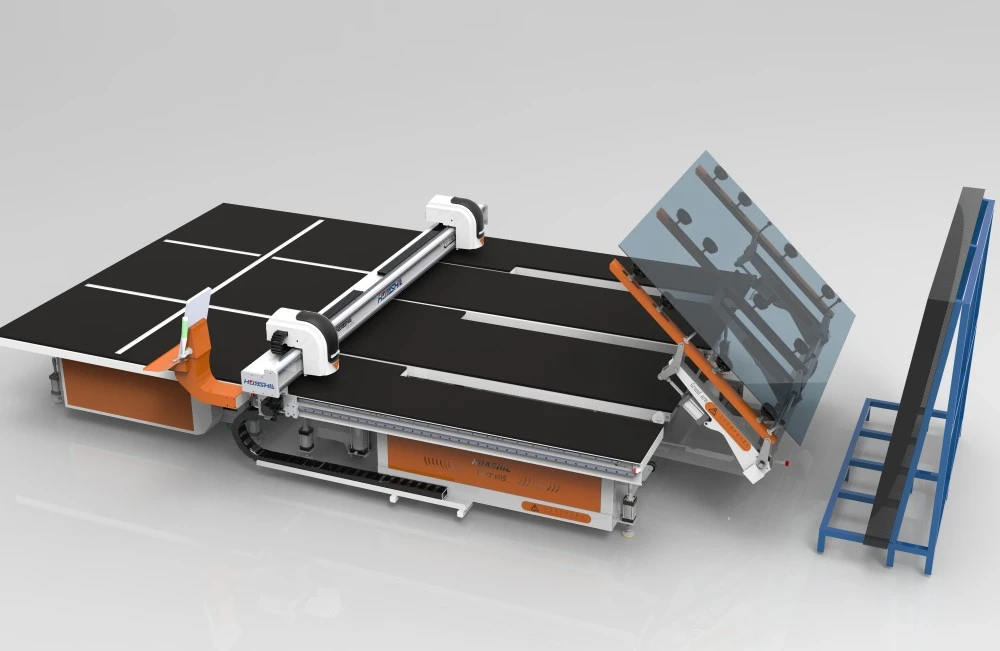

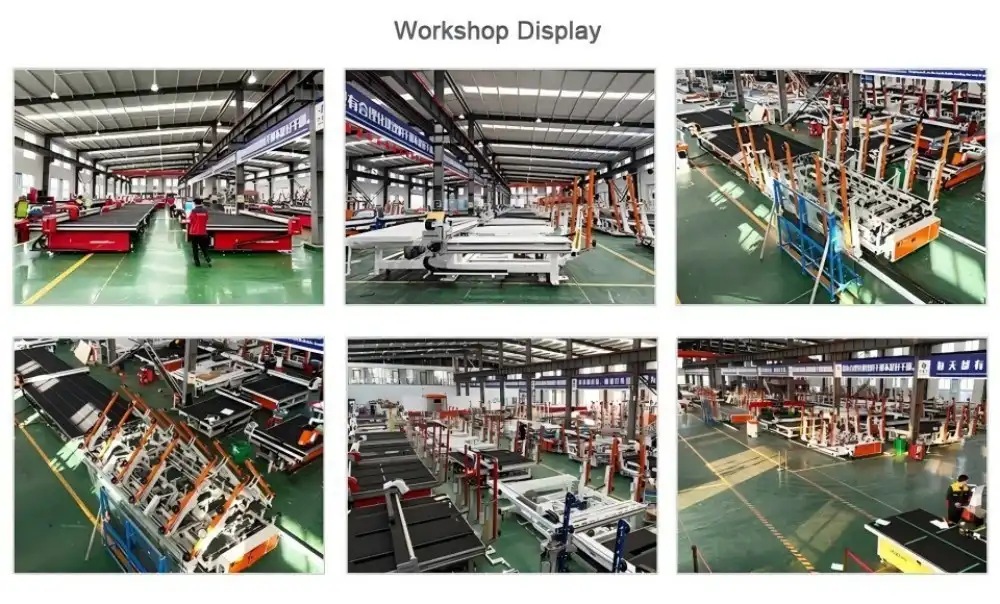

If you're looking to upgrade your glass cutting capabilities or implement a state-of-the-art automatic glass cutting line for low-e glass production, Shandong Huashil Automation Technology Co., LTD is here to help. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced solutions tailored to your specific needs. Our cutting-edge technology, combined with stable quality and excellent service, has made us a preferred choice for customers worldwide.

Ready to take your glass cutting operations to the next level? Contact us today at salescathy@sdhuashil.com to discuss how our automatic glass cutting solutions can transform your production line and give you a competitive edge in the low-e glass market.

References

1. Johnson, A. R. (2022). Advanced Control Systems in Modern Glass Manufacturing. Journal of Industrial Automation, 15(3), 78-92.

2. Smith, B. L., & Thompson, C. D. (2021). Precision Cutting Technologies for Low-Emissivity Glass Production. International Glass Technology Review, 36(2), 145-160.

3. Martinez, E. G., et al. (2023). Integration of PLC and CNC Systems in High-Precision Glass Processing. Automation in Manufacturing, 28(4), 312-328.

4.Wong, K. H. (2022). Communication Protocols in Smart Glass Manufacturing Facilities. Industrial Internet of Things Quarterly, 7(1), 55-70.