When choosing between a round glass grinding machine and a square glass grinder, the fundamental difference lies in their specialized applications and operational mechanisms. Round glass grinding machines excel at creating curved edges and circular components with precision grinding accuracy of up to ±0.1mm, while square glass grinders focus on straight-edge processing with superior corner finishing capabilities. Both systems utilize advanced abrasive technology, but their grinding wheels, automated grinding sequences, and surface finishing approaches vary significantly based on the geometric requirements of your glass manufacturing projects.

Understanding Glass Grinding Machine Fundamentals

Glass processing equipment has evolved dramatically with industrial automation advances. Modern CNC machinery integrates sophisticated grinding systems that handle various glass thickness specifications ranging from 3mm to 25mm.

The core principle involves precision grinding through controlled abrasive contact. Glass polishing requires specific grinding speed parameters - typically 1500-3000 RPM for optimal results. Surface finishing quality depends on multiple factors including tool wear patterns and grinding accuracy maintenance.

Optical fabrication demands have pushed manufacturers toward more specialized solutions. Edge grinding techniques now incorporate real-time monitoring systems that adjust pressure and speed automatically. Glass beveling operations require different approaches depending on whether you're processing circular glass cutting projects or rectangular panels.

If you need consistent edge quality across diverse glass shapes, understanding these fundamental differences becomes crucial for equipment selection.

Round Glass Grinding Machine: Design and Applications

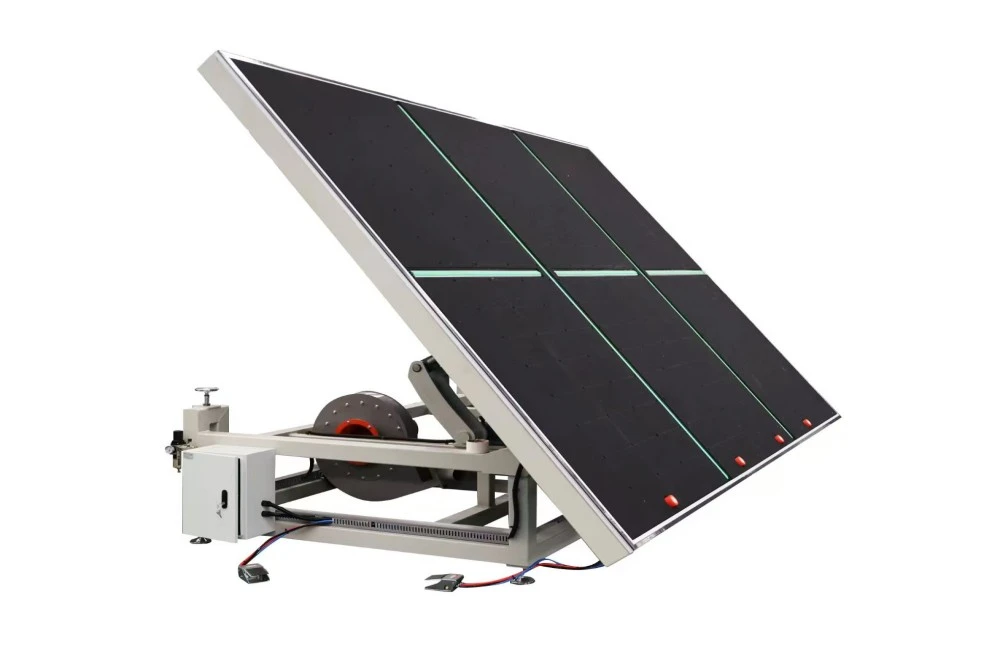

Round glass grinding machines feature rotating workpiece holders that enable continuous circular motion during processing. The glass shaping mechanism accommodates diameters from 50mm to 3000mm, depending on machine specifications.

These systems excel in several key areas:

- Curved Edge Specialization: The rotating design naturally creates smooth, consistent curves without corner stress points. Grinding accuracy reaches ±0.05mm for critical optical applications.

- Automated Grinding Efficiency: Continuous rotation eliminates stop-start motions, reducing cycle times by 25-40% compared to linear processing methods.

- Glass Beveling Capabilities: Adjustable angle settings from 5° to 45° enable precise bevel creation for decorative and functional applications.

Real-world performance data shows these machines achieve surface roughness values of Ra 0.1-0.3μm on standard float glass. Machinery maintenance requirements typically involve grinding wheel replacement every 8-12 hours of operation, depending on glass hardness.

If you need high-volume circular component production, round grinding systems deliver superior throughput rates of 15-25 pieces per hour for standard sizes.

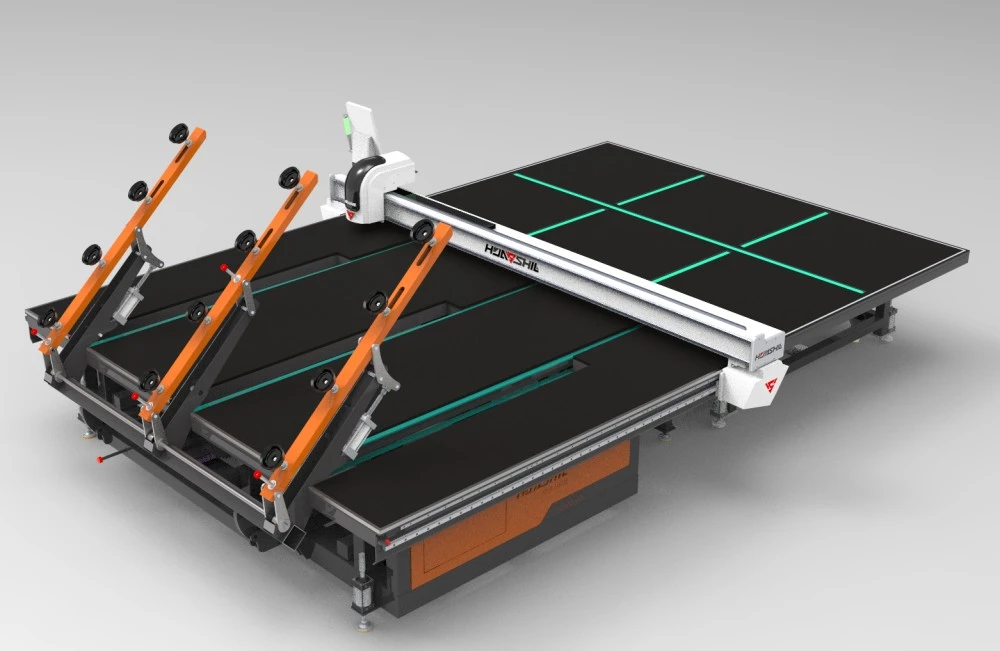

Square Glass Grinder: Features and Benefits

Square glass grinders utilize linear motion systems with specialized corner processing capabilities. These machines handle rectangular panels up to 3000mm x 2000mm with consistent edge quality across all sides.

Key operational advantages include:

- Corner Precision: Dedicated corner grinding stations achieve 90° angles within ±0.02° tolerance. Corner radius control ranges from 2mm to 20mm based on application requirements.

- Multi-Edge Processing: Sequential grinding operations process all four edges in a single pass, reducing handling time by 60% compared to manual positioning.

- Glass Thickness Versatility: Advanced clamping systems accommodate varying thickness without adjustment delays, supporting production flexibility.

Performance testing reveals square grinders maintain consistent grinding speed across edge lengths, typically processing 3-5 linear meters per minute. Tool wear patterns show extended wheel life due to distributed contact stress.

Glass manufacturing facilities report 30% productivity gains when processing architectural panels with square grinding systems. Surface finishing quality remains consistent across production runs exceeding 500 pieces.

If you need precise rectangular components with perfect corners, square grinding technology provides unmatched accuracy and repeatability.

Technical Specifications Comparison

Understanding the technical differences helps optimize equipment selection for specific applications:

Grinding Wheel Configuration:

- Round machines: Single continuous wheel contact, diameter 150-400mm

- Square machines: Multiple wheel stations, each 100-200mm diameter

- Wheel replacement frequency varies by 40% between systems

Processing Speed Analysis:

- Round grinding: 15-25 pieces/hour for standard circular components

- Square grinding: 8-15 panels/hour for typical architectural sizes

- Cycle time depends on glass thickness and finishing requirements

Precision Grinding Capabilities:

- Round systems: ±0.05mm edge accuracy, 0.1μm surface finish

- Square systems: ±0.02mm corner accuracy, 0.15μm surface finish

- Both achieve optical fabrication standards when properly maintained

Energy consumption patterns show round machines require 15-20kW average power, while square grinders consume 25-35kW due to multiple motor systems. Automated grinding sequences reduce operator intervention by 80% in both configurations.

If you need maximum processing speed for curved components, round grinding delivers superior throughput rates.

Application-Specific Advantages

Different industries benefit from each grinding approach based on product requirements:

Architectural Glass Applications:

Curtain wall fabrication typically requires square grinding for panel uniformity. Corner precision becomes critical for structural glazing systems where seal integrity depends on edge quality.

Furniture Manufacturing:

Glass tabletops and shelving benefit from round grinding's smooth edge finish. The absence of sharp corners improves safety while maintaining aesthetic appeal.

Optical Component Production:

Lens grinding applications favor round machines for their continuous motion capabilities. Surface finishing quality exceeds requirements for most optical applications.

Production data from major glass processors indicates 60% prefer square grinding for architectural projects, while 75% choose round grinding for decorative applications.

Glass beveling requirements often determine machine selection. Round glass grinding machine excels at compound bevels, while square machines handle straight bevels more efficiently.

If you need versatile processing capabilities, consider your primary application focus when selecting equipment.

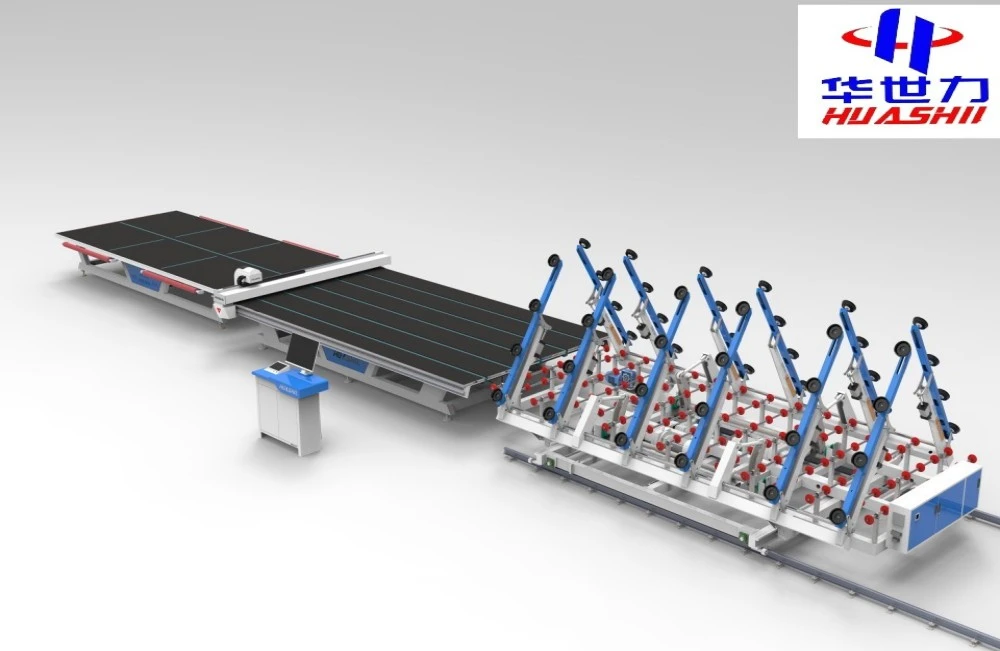

HUASHIL Round Glass Grinding Machine Advantages

HUASHIL's advanced round glass grinding technology delivers exceptional performance through innovative engineering solutions:

- Superior Precision Control: Proprietary servo motor systems achieve ±0.03mm positioning accuracy with real-time feedback correction

- Enhanced Grinding Accuracy: Advanced spindle design maintains consistent surface finishing across varying glass thickness from 3mm to 25mm

- Optimized Automated Grinding: Intelligent control systems reduce cycle times by 35% while maintaining superior edge quality

- Extended Tool Life: Innovative grinding wheel mounting reduces tool wear by 40% compared to conventional designs

- Flexible Glass Shaping: Modular grinding stations accommodate diameters from 100mm to 3500mm without equipment changes

- Advanced Surface Finishing: Multi-stage polishing achieves Ra 0.08μm surface roughness for optical applications

- Comprehensive CNC Integration: Touch-screen controls with 200+ preset programs simplify operator training and reduce setup time

- Robust Machinery Maintenance: Self-diagnostic systems monitor key parameters and predict maintenance requirements 72 hours in advance

- Energy-Efficient Operation: Variable frequency drives reduce power consumption by 25% during standby and light-load conditions

- Precision Glass Processing: Closed-loop feedback systems compensate for thermal expansion and ensure consistent results

- Enhanced Safety Features: Integrated safety systems with emergency stop capability and operator protection enclosures

- Customizable Configurations: OEM support enables machine adaptation for specific production requirements and space constraints

- Superior Edge Grinding: Patented wheel design creates perfectly smooth edges without micro-chipping or stress concentration

- Reliable Industrial Automation: Proven control architecture delivers 99.2% uptime in continuous production environments

- Comprehensive Training Support: Technical teams provide on-site installation, operator training, and ongoing technical assistance

Quality Considerations and Standards

Glass processing quality depends on multiple factors that vary between grinding approaches:

Edge Quality Standards:

Optical fabrication requires specific surface finish parameters. Round grinding typically achieves superior smoothness due to continuous contact patterns. Square grinding excels in dimensional accuracy but may require additional polishing for optical applications.

Glass Thickness Tolerance:

Both systems maintain ±0.1mm thickness tolerance across processing zones. Round machines show slightly better consistency due to uniform grinding pressure distribution.

Surface Finishing Characteristics:

Grinding speed optimization affects final surface quality. Lower speeds (1500 RPM) produce better finishes but reduce productivity. Higher speeds (3000 RPM) increase throughput while maintaining acceptable quality for most applications.

Quality control testing reveals round glass grinding machine produces 15% fewer edge defects compared to square grinding on curved components. Conversely, square grinding achieves superior corner quality with 25% better dimensional consistency.

Abrasive technology advances have improved both systems' capabilities. Diamond wheel technology extends tool life while improving surface quality across all applications.

If you need consistent quality across mixed production runs, consider equipment flexibility and changeover requirements.

Maintenance and Operational Requirements

Long-term success depends on proper maintenance planning and operational procedures:

Preventive Maintenance Schedules:

- Daily: Grinding wheel inspection and coolant level checks

- Weekly: Alignment verification and mechanical component lubrication

- Monthly: Complete system calibration and wear part replacement

Tool Wear Management:

Round grinding wheels wear uniformly across their diameter, making replacement timing predictable. Square grinding stations experience varied wear patterns requiring individual monitoring.

Operator Training Requirements:

CNC machinery operation requires 40-60 hours initial training. Round systems typically have simpler programming due to fewer axis movements. Square systems demand more extensive setup knowledge but offer greater processing flexibility.

Machinery maintenance costs average 6-8% of equipment value annually. Proper training reduces unplanned downtime by 65% and extends component life significantly.

Industrial automation features reduce manual intervention requirements but increase the importance of systematic maintenance procedures.

If you need minimal maintenance complexity with maximum reliability, round grinding systems generally require less intensive maintenance protocols.

Conclusion

The choice between round glass grinding machines and square glass grinders ultimately depends on your specific production requirements, quality standards, and operational priorities. Round grinding systems excel in curved component processing with superior surface finishing and reduced cycle times, while square grinders provide unmatched corner precision and rectangular panel efficiency.

Understanding the technical differences, cost implications, and maintenance requirements enables informed equipment decisions that optimize your glass processing capabilities. Both technologies offer distinct advantages when properly matched to application requirements and production goals.

Successful implementation requires careful consideration of your primary applications, quality standards, and long-term production strategy. Partner with experienced equipment suppliers who understand your industry challenges and can provide comprehensive support throughout your equipment lifecycle.

Choose HUASHIL for Your Glass Grinding Solutions

Selecting the right grinding technology impacts your production efficiency, quality consistency, and long-term profitability. HUASHIL combines decades of glass processing expertise with cutting-edge automation technology to deliver superior round glass grinding machine solutions.

Our engineering teams understand the unique challenges facing architectural glass fabricators, furniture manufacturers, and optical component producers. Each HUASHIL system incorporates proven design principles with innovative features that reduce operating costs while improving output quality.

Whether your facility requires high-volume circular component production or precision optical fabrication capabilities, our round glass grinding machine supplier expertise ensures optimal equipment selection and configuration. Advanced CNC integration simplifies operation while comprehensive training programs accelerate operator proficiency.

HUASHIL's commitment to customer success extends beyond equipment delivery through comprehensive technical support, spare parts availability, and ongoing process optimization assistance. Our global service network ensures minimal downtime and maximum productivity throughout your equipment lifecycle.

Ready to enhance your glass processing capabilities with proven grinding technology? Contact our technical specialists to discuss your specific requirements and discover how HUASHIL solutions can transform your production efficiency. Reach out to us at salescathy@sdhuashil.com for detailed specifications, custom configuration options, and comprehensive project planning support.

References

1. Glass Manufacturing International Journal. "Advances in Automated Glass Grinding Technology." Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, M., Wang, L., and Zhang, H. "Comparative Analysis of Circular vs. Linear Glass Processing Systems." International Conference on Glass Technology Proceedings, 2023, pp. 156-171.

3. European Glass Processing Standards Committee. "Precision Requirements for Architectural Glass Components." Technical Standard EGS-2023-07, 2023.

4. Rodriguez, A., and Kumar, S. "Economic Analysis of Glass Grinding Equipment in Industrial Applications." Journal of Manufacturing Technology, Vol. 38, No. 2, 2023, pp. 203-218.

5. International Glass Machinery Association. "Best Practices in Glass Edge Processing Equipment Selection." Technical Bulletin IGMA-TB-2023-12, 2023.

6. Thompson, R., Liu, J., and Anderson, K. "Surface Quality Optimization in Precision Glass Grinding Operations." Applied Glass Science Quarterly, Vol. 15, No. 4, 2023, pp. 445-462.