CNC stone cutting machines have revolutionized the stone fabrication industry, offering precision, efficiency, and versatility. However, with great power comes great responsibility. Ensuring proper safety measures are in place is crucial when operating these powerful machines. In this comprehensive guide, we'll explore the essential safety considerations for using a CNC stone cutting machine, helping you maintain a secure work environment while maximizing productivity.

Key Safety Features to Look for in CNC Machines

When investing in a CNC stone cutting machine, it's vital to prioritize safety features. Here are some key elements to consider:

- Emergency Stop Buttons: Easily accessible and clearly marked emergency stop buttons are crucial for quickly halting machine operations in case of any unforeseen issues.

- Safety Guards: Protective enclosures or barriers around moving parts help prevent accidental contact with dangerous components.

- Automatic Tool Changers: These reduce the need for manual intervention, minimizing the risk of injury during tool changes.

- Dust Collection Systems: Efficient dust extraction systems help maintain air quality and reduce the risk of respiratory issues.

- Safety Interlocks: These prevent the machine from operating when safety guards are open or removed.

- Light Curtains: Photoelectric sensors that detect any intrusion into the working area and immediately stop the machine.

Investing in a CNC stone cutting machine with these safety features not only protects your workers but also ensures compliance with industry regulations. Remember, a safe workplace is a productive workplace.

Common Hazards and How to Avoid Them

Understanding potential risks is the first step in preventing accidents. Let's explore some common hazards associated with CNC stone cutting machines and strategies to mitigate them:

Flying Debris

Stone cutting processes can generate high-speed projectiles, posing a significant risk to operators and bystanders.

Prevention strategies:

- Install proper machine guarding and safety screens

- Ensure operators wear appropriate personal protective equipment (PPE), including safety glasses and face shields

- Implement regular maintenance to prevent tool breakage

Dust Inhalation

Cutting stone produces fine particulate matter that can cause respiratory issues when inhaled over time.

Prevention strategies:

- Install and maintain an effective dust collection system

- Provide workers with proper respiratory protection

- Implement wet cutting techniques when possible to reduce airborne dust

Noise Exposure

CNC stone cutting machines can generate high noise levels, potentially leading to hearing damage.

Prevention strategies:

- Implement noise reduction measures, such as sound-absorbing materials around the machine

- Provide workers with appropriate hearing protection

- Conduct regular noise level assessments and implement controls as needed

Electrical Hazards

Improper electrical connections or damaged wiring can lead to electric shocks or fires.

Prevention strategies:

- Ensure proper grounding of all electrical equipment

- Conduct regular inspections of electrical systems

- Train workers on electrical safety and proper lockout/tagout procedures

Crushing or Entanglement

Moving parts of the CNC stone cutting machine pose risks of crushing or entangling workers' limbs or clothing.

Prevention strategies:

- Install and maintain proper machine guarding

- Implement clear safety protocols for machine operation

- Ensure workers wear appropriate clothing without loose parts that could get caught in machinery

By addressing these common hazards, you can significantly reduce the risk of accidents and create a safer working environment for your team.

Best Safety Practices for Operators

Proper training and adherence to safety protocols are essential for anyone operating a CNC stone cutting machine. Here are some best practices to implement:

Comprehensive Training

Ensure all operators receive thorough training on machine operation, safety features, and emergency procedures. This should include:

- Proper machine startup and shutdown procedures

- Understanding of control systems and programming

- Recognition of potential hazards and appropriate responses

- Proper use of personal protective equipment (PPE)

Regular Maintenance and Inspections

Implement a rigorous maintenance schedule to keep your CNC stone cutting machine in optimal condition:

- Conduct daily pre-operation checks

- Perform regular cleaning and lubrication

- Schedule professional maintenance at recommended intervals

- Keep detailed maintenance logs

Proper Material Handling

Safe material handling is crucial to prevent injuries and ensure smooth operation:

- Use appropriate lifting equipment for heavy stone slabs

- Train workers on proper lifting techniques

- Ensure proper storage and organization of materials

Clear Communication Protocols

Establish clear communication procedures to enhance safety:

- Implement a system for reporting safety concerns or near-misses

- Conduct regular safety meetings to discuss potential hazards and improvements

- Encourage open dialogue between operators and management about safety issues

Personal Protective Equipment (PPE)

Ensure all operators and nearby workers wear appropriate PPE, including:

- Safety glasses or face shields

- Hearing protection

- Dust masks or respirators

- Steel-toed boots

- Gloves when handling materials

Emergency Response Planning

Develop and regularly practice emergency response procedures:

- Conduct regular emergency drills

- Clearly mark emergency exits and keep them unobstructed

- Ensure first aid kits are readily available and fully stocked

- Train multiple employees in first aid and CPR

By implementing these best practices with a CNC stone cutting machine, you can create a culture of safety that protects your workers and enhances overall productivity. Remember, safety is an ongoing process that requires continuous attention and improvement.

Conclusion

Operating a CNC stone cutting machine manufacturer efficiently and safely requires a combination of proper equipment, thorough training, and vigilant adherence to safety protocols. By prioritizing safety features when selecting a machine, addressing common hazards, and implementing best practices for operators, you can significantly reduce the risk of accidents and create a secure working environment.

Remember, safety is not just about compliance—it's about protecting your most valuable asset: your workforce. A safe workplace leads to increased productivity, higher morale, and ultimately, a more successful business.

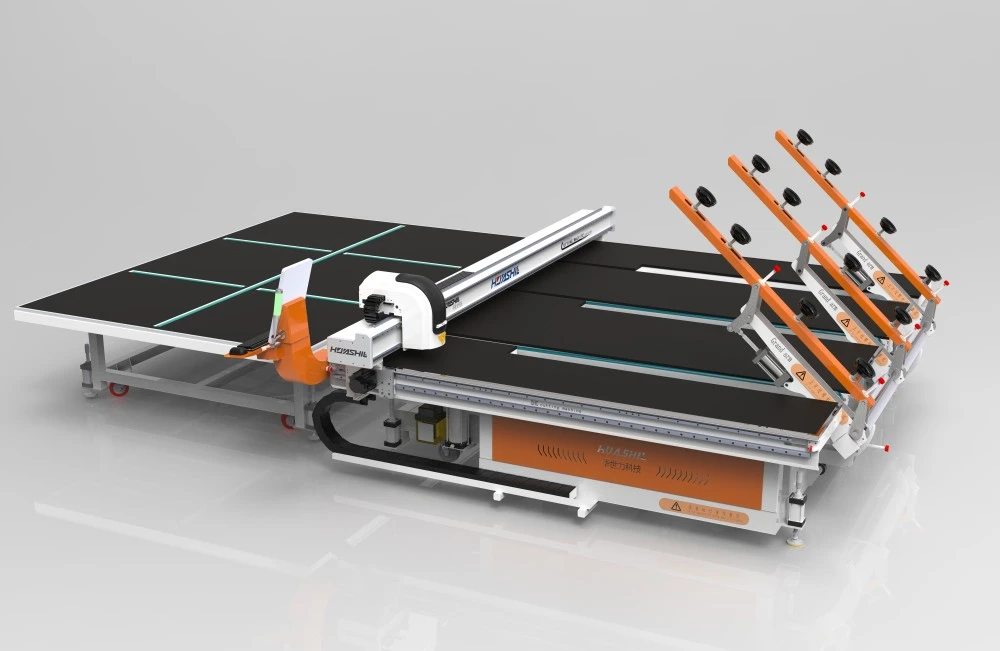

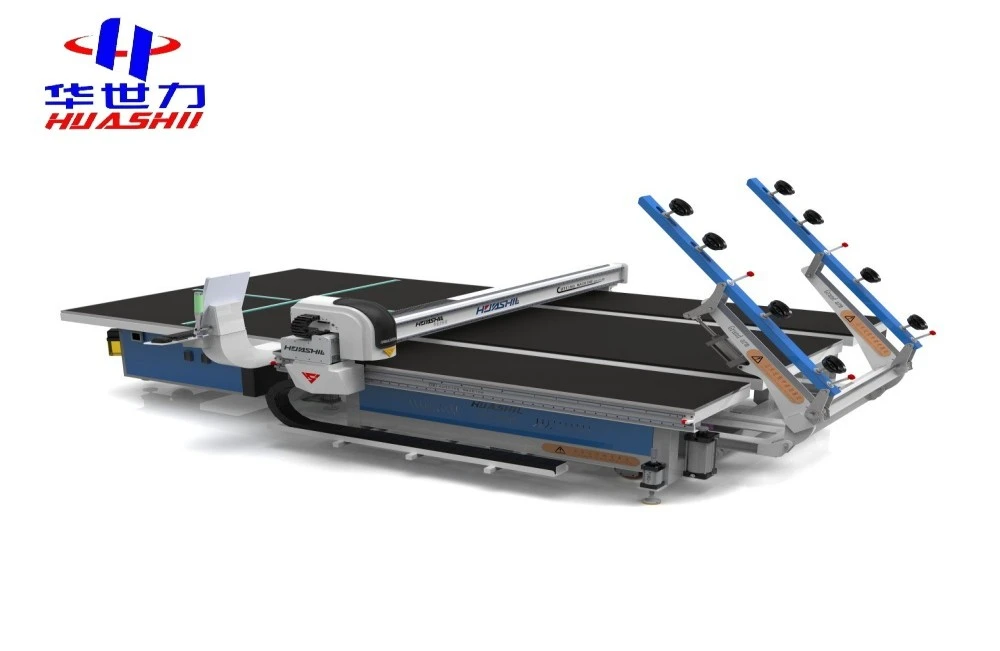

At Shandong Huashil Automation Technology Co., Ltd., we understand the importance of safety in CNC stone cutting operations. Our advanced machines are designed with state-of-the-art safety features, ensuring both precision and protection. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to providing top-quality CNC stone cutting machines that meet the highest safety standards.

FAQ

Q1: How often should I conduct safety training for CNC stone cutting machine operators?

A: Safety training should be conducted regularly, typically on an annual basis at a minimum. However, it's also important to provide refresher training whenever new equipment is introduced, procedures change, or if there's been a safety incident. Additionally, new operators should receive comprehensive training before operating the machine independently.

Q2: Are there any specific regulations governing the use of CNC stone cutting machines?

A: Yes, there are several regulations that may apply, depending on your location and industry. In the United States, for example, OSHA (Occupational Safety and Health Administration) provides guidelines for machine guarding and other safety aspects. It's crucial to familiarize yourself with local and national regulations and ensure your operations comply with all relevant standards.

Q3: What should I do if a safety feature on my CNC stone cutting machine malfunctions?

A: If you notice any malfunction in a safety feature, immediately stop using the machine and follow these steps: 1) Engage the emergency stop if the machine is running. 2) Notify your supervisor or safety officer. 3) Place a clear "Do Not Operate" sign on the machine. 4) Document the issue in detail. 5) Contact the manufacturer or a certified technician for repair. Never attempt to bypass safety features or operate the machine with malfunctioning safety equipment.

Q4: How can I ensure proper dust control when using a CNC stone cutting machine?

A: Effective dust control is crucial for both health and safety. Implement these measures: 1) Use a high-quality dust collection system designed for stone cutting. 2) Regularly maintain and clean the dust collection system. 3) Consider wet cutting techniques when possible. 4) Ensure proper ventilation in the work area. 5) Provide workers with appropriate respiratory protection. 6) Conduct regular air quality tests to ensure dust levels remain within safe limits.

CNC Stone Cutting Machine Safety: Your Ultimate Guide | HUASHIL

At Shandong Huashil Automation Technology Co., LTD, we're committed to providing not just top-quality CNC stone cutting machines, but also the knowledge and support you need to operate them safely and efficiently. Our team of experts is ready to assist you in selecting the right machine for your needs, complete with all necessary safety features. We also offer comprehensive training and ongoing support to ensure your team can operate our machines with confidence and safety.

Ready to elevate your stone cutting operations with a focus on safety and efficiency? Contact us today at salescathy@sdhuashil.com to discuss your specific requirements. Let HUASHIL be your partner in safe, productive, and innovative stone cutting solutions.

References

1. Smith, J. (2022). "Safety Considerations in CNC Stone Cutting Operations." Journal of Industrial Safety, 45(3), 78-92.

2. Johnson, A. & Brown, T. (2021). "Best Practices for CNC Machine Safety in the Stone Fabrication Industry." Stone World Magazine, 38(7), 52-58.

3. National Institute for Occupational Safety and Health. (2023). "Preventing Injuries in the Stone Cutting Industry: A Comprehensive Guide."

4. European Agency for Safety and Health at Work. (2022). "Risk Assessment for CNC Machine Operators in the Stone Industry."