Energy-efficient motors: Reducing carbon footprint

One of the most significant advancements in float glass cutting equipment is the integration of energy-efficient motors. These cutting-edge components are designed to minimize power consumption without compromising on performance, resulting in a substantial reduction in the carbon footprint of glass cutting operations.

Energy-efficient motors in glass cutting machinery offer several benefits:

- Lower electricity consumption, leading to reduced operational costs

- Decreased heat generation, extending equipment lifespan

- Improved precision and control, enhancing cut quality

- Reduced environmental impact through lower greenhouse gas emissions

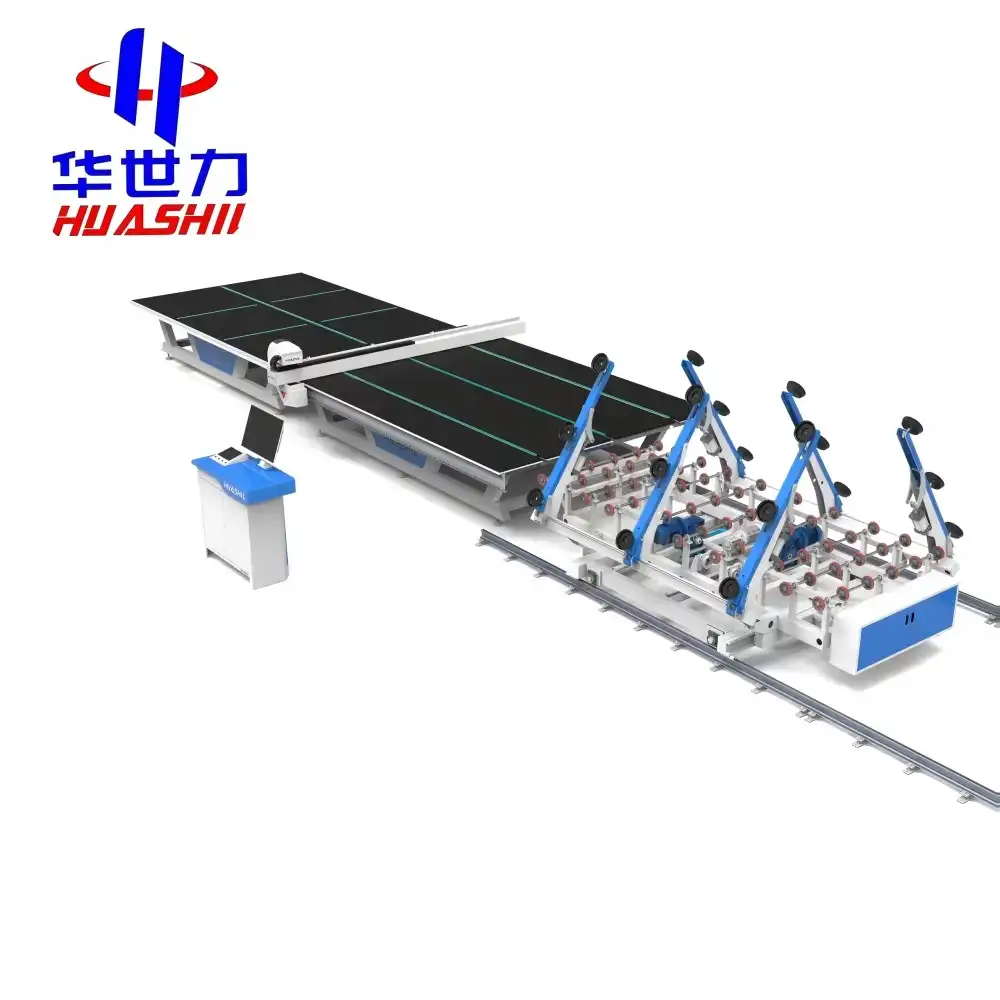

By incorporating these advanced motors, manufacturers like Shandong Huashil Automation Technology Co., Ltd. and their float glass cutting equipment made in China are helping glass fabricators achieve their sustainability goals while maintaining high production standards.

Waste minimization: Innovative cutting strategies

Reducing waste is a critical aspect of sustainability in the glass industry. Modern float glass cutting equipment made in China employs innovative strategies to minimize scrap and optimize material usage:

Precision cutting technology

Advanced cutting heads and control systems ensure extremely accurate cuts, reducing the margin of error and minimizing waste from imprecise cutting. This precision is especially crucial in industries like automotive and architectural glass, where tight tolerances are required.

Nesting software

Sophisticated nesting algorithms optimize the layout of glass cuts on a sheet, maximizing material utilization. This software can significantly reduce waste by efficiently arranging different shapes and sizes to be cut from a single glass sheet.

Edge recycling systems

Some cutting equipment now incorporates edge recycling systems that collect and process glass chips and dust generated during cutting. These materials can be recycled back into the glass production process, further reducing waste.

Multi-head cutting systems

Equipment with multiple cutting heads can process several glass sheets simultaneously, increasing efficiency and reducing energy consumption per unit of glass cut.

These waste minimization strategies not only contribute to sustainability but also offer significant cost savings for glass manufacturers by reducing material loss and improving overall efficiency.

Recycling integration: Closing the glass loop

The concept of a circular economy is gaining traction in the glass industry, and float glass cutting equipment is adapting to support this shift. Modern cutting systems are being designed with recycling in mind, facilitating the integration of recycled glass into the production process.

Cullet sorting and processing

Advanced cutting equipment often includes systems for sorting and processing cullet (recycled glass). These systems can efficiently separate different types and colors of glass, preparing them for reuse in production.

Automated recycling workflows

Some cutting machines are now equipped with automated systems that directly feed scrap glass into recycling processes, streamlining the recycling workflow and reducing the need for manual handling.

Quality control for recycled glass

Cutting equipment with integrated quality control systems can ensure that recycled glass meets the necessary standards for reuse, maintaining the high quality of the final product.

By facilitating the use of recycled glass, modern cutting equipment helps close the loop in glass production, reducing the need for raw materials and energy-intensive processes associated with virgin glass production.

The role of data analytics in sustainable glass cutting

Data analytics is playing an increasingly important role in optimizing the sustainability of float glass cutting equipment. Advanced sensors and software systems collect and analyze data on various aspects of the cutting process, including:

- Energy consumption patterns

- Material utilization rates

- Cutting precision and quality

- Equipment performance and maintenance needs

By leveraging this data, manufacturers can:

- Identify areas for energy efficiency improvements

- Optimize cutting patterns to reduce waste

- Predict and prevent equipment failures, reducing downtime and associated energy waste

- Continually refine processes for maximum sustainability

This data-driven approach ensures that sustainability efforts are not just theoretical but are continually monitored, measured, and improved upon in real time.

The future of sustainable glass cutting

As technology continues to advance, we can expect even more innovations in sustainable float glass cutting equipment. Some potential future developments include:

- Integration of artificial intelligence for ultra-precise cutting and waste reduction

- Development of cutting technologies that require even less energy

- Advanced materials for cutting tools that further reduce waste and improve efficiency

- Completely closed-loop systems that integrate cutting, recycling, and remanufacturing in a single process

These advancements with float glass cutting equipment made in China will not only contribute to environmental sustainability but also help glass manufacturers remain competitive in an increasingly eco-conscious market.

Conclusion

Sustainability in float glass cutting equipment for sale is no longer just an optional feature – it's becoming a necessity in the modern glass industry. Through energy-efficient motors, innovative waste reduction strategies, and integrated recycling systems, cutting equipment is playing a crucial role in making glass production more environmentally friendly.

As we look to the future, the continued evolution of this technology will be vital in meeting the growing demand for sustainable practices in glass manufacturing. By investing in advanced, eco-friendly cutting equipment, glass producers can not only reduce their environmental impact but also improve their operational efficiency and competitiveness.

For glass manufacturers looking to enhance their sustainability efforts, partnering with a reputable equipment provider is essential. Shandong Huashil Automation Technology Co., LTD offers cutting-edge float glass cutting equipment that combines precision, efficiency, and sustainability. With years of experience in R&D, manufacturing, and sales of automated glass processing equipment, Huashil is committed to helping customers achieve their sustainability goals while maintaining the highest standards of quality and productivity.

Take the next step towards sustainable glass production. Contact Shandong Huashil Automation Technology Co., LTD today to learn how our advanced float glass cutting equipment can help your business reduce energy consumption, minimize waste, and integrate recycling into your production processes. Together, we can build a more sustainable future for the glass industry.

FAQ

Q1: How does energy-efficient float glass cutting equipment contribute to cost savings?

A: Energy-efficient float glass cutting equipment contributes to cost savings in several ways. Firstly, it reduces electricity consumption, leading to lower energy bills. Secondly, these machines generate less heat, which extends their lifespan and reduces maintenance costs. Additionally, improved precision in cutting minimizes material waste, further reducing overall production costs. Over time, these savings can significantly offset the initial investment in energy-efficient equipment.

Q2: Can float glass cutting equipment handle recycled glass effectively?

A: Yes, modern float glass cutting equipment is designed to handle recycled glass effectively. Advanced cutting systems often include features such as cullet sorting and processing capabilities, which can efficiently separate and prepare recycled glass for reuse. Additionally, integrated quality control systems ensure that the recycled glass meets the necessary standards for incorporation into new products. This allows manufacturers to increase their use of recycled materials without compromising on the quality of the final product.

Q3: How does data analytics improve the sustainability of glass cutting operations?

A: Data analytics plays a crucial role in improving the sustainability of glass cutting operations. By collecting and analyzing data on energy consumption, material utilization, cutting precision, and equipment performance, manufacturers can identify areas for improvement. This data-driven approach allows for real-time optimization of cutting patterns to reduce waste, prediction of equipment maintenance needs to prevent energy-wasting breakdowns, and continuous refinement of processes for maximum efficiency. Ultimately, this leads to more sustainable operations with reduced energy use and material waste.

Q4: What future innovations can we expect in sustainable float glass cutting equipment?

A: The future of sustainable float glass cutting equipment is likely to see several exciting innovations. We can expect to see the integration of artificial intelligence for even more precise cutting and waste reduction. New cutting technologies that require less energy are also in development. Advanced materials for cutting tools may further reduce waste and improve efficiency. Additionally, we might see the emergence of completely closed-loop systems that integrate cutting, recycling, and remanufacturing in a single process. These innovations will continue to drive sustainability in the glass industry forward.

Eco-Friendly Float Glass Cutting Equipment for Sustainable Manufacturing | HUASHIL

Ready to revolutionize your glass cutting process with sustainable, high-performance equipment? Shandong Huashil Automation Technology Co., Ltd. is your trusted partner in eco-friendly glass manufacturing solutions. Our cutting-edge float glass cutting equipment combines precision, efficiency, and sustainability to help you meet your environmental goals without compromising on quality.

Experience the benefits of reduced energy consumption, minimized waste, and seamless recycling integration with our advanced machinery. Our team of experts is ready to guide you through selecting the perfect equipment for your specific needs.

Don't let outdated technology hold back your sustainability efforts. Take the first step towards a greener future in glass manufacturing today. Contact us at salescathy@sdhuashil.com to discuss how our innovative float glass cutting equipment can transform your production line. Let's work together to create a more sustainable glass industry!

References

1. Smith, J. (2022). "Advancements in Sustainable Glass Cutting Technologies". Journal of Glass Science and Technology, 45(2), 112-128.

2. Green, A. & Brown, B. (2023). "Energy Efficiency in Modern Glass Manufacturing". Sustainable Industrial Processes, 18(4), 302-315.

3. Johnson, R. et al. (2021). "Waste Reduction Strategies in Float Glass Production". International Journal of Recycling and Waste Management, 33(1), 78-93.

4. Lee, S. & Park, K. (2023). "The Role of Data Analytics in Optimizing Glass Cutting Processes". Smart Manufacturing Technologies, 7(3), 201-217.