In the world of precision glasswork, the right tools can make all the difference between a masterpiece and a mishap. When it comes to delicate glass cutting, small CNC glass cutting machines have revolutionized the industry, offering unparalleled accuracy and efficiency. These compact powerhouses are essential for craftsmen and manufacturers alike, enabling intricate designs and perfect cuts that were once only achievable by hand. As the demand for customized glass products continues to rise, the importance of selecting the ideal CNC machine for your specific needs cannot be overstated. Whether you're crafting bespoke mirrors, creating artistic glass installations, or producing precision components for the tech industry, the capabilities of your CNC glass cutter will directly impact the quality of your output. In this comprehensive guide, we'll explore the key features that make a CNC machine suitable for delicate glasswork, highlight some of the top performers in detailed engraving and micro-cutting, and compare critical specifications to help you make an informed decision. Let's dive into the crystalline world of small CNC glass cutting technology and discover how these machines are shaping the future of glass craftsmanship.

What Features are Essential for a CNC Machine Handling Delicate Glass?

When working with fragile materials like glass, the features of your CNC machine can mean the difference between flawless execution and costly mistakes. Here are the critical elements to consider:

Precision and Accuracy

The hallmark of any quality small CNC glass cutting machine is its ability to make precise cuts with minimal deviation. Look for machines with high-resolution stepper motors and advanced motion control systems that can achieve accuracies down to microns. This level of precision is crucial for creating intricate patterns and ensuring that pieces fit together perfectly in complex assemblies.

Vibration Control

Glass is unforgiving when it comes to vibrations. Even minor tremors can lead to chips, cracks, or complete breakage. The best CNC machines for delicate glasswork incorporate robust vibration dampening systems. This might include isolated motor mounts, reinforced frames, and specialized cutting tools designed to minimize vibration transfer to the workpiece.

Cutting Speed Control

The ability to finely adjust cutting speed is paramount when working with glass. Too fast, and you risk shattering the material; too slow, and you may encounter heat-related issues or inefficiency. Look for machines that offer variable speed control and have pre-programmed settings for different types of glass and cutting operations.

Coolant Systems

Effective cooling is essential to prevent thermal stress in the glass during cutting. Advanced CNC glass cutters often feature integrated coolant systems that precisely direct a cooling medium (usually water or a specialized cutting fluid) to the point of contact. This not only prevents heat-related damage but also helps to flush away debris, ensuring a clean cut.

Software Integration

The software controlling your CNC machine should be both powerful and user-friendly. Look for systems that support a wide range of file formats and offer features like nesting (to optimize material usage) and simulation (to preview cuts before execution). The ability to easily adjust parameters and create custom toolpaths is also crucial for working with different glass types and thicknesses.

Material Handling

Delicate glass requires gentle but secure handling. The best CNC machines for this purpose often include vacuum suction systems or specialized clamps that hold the glass firmly without applying excessive pressure. Some advanced models even incorporate automated loading and unloading systems to minimize the risk of human error during material handling.

Dust Collection

Glass cutting produces fine particles that can be hazardous if inhaled and can interfere with the machine's operation if allowed to accumulate. An efficient dust collection system is not just a convenience but a necessity for maintaining a safe and clean working environment.

Which Machines Excel at Detailed Engraving and Micro-Cutting?

When it comes to the most intricate glass work, certain machines stand out for their exceptional capabilities in detailed engraving and micro-cutting. Let's explore some of the top performers in this specialized field:

The Precision Maestro Series

Known for its unparalleled accuracy, the Precision Maestro series of small cnc glass cutting machines offers a resolution of up to 0.001mm, making it ideal for the most demanding micro-cutting tasks. Its advanced optical recognition system allows for precise alignment and cut-to-print capabilities, essential for creating complex patterns and designs on glass surfaces.

GlassArt Pro X3

The GlassArt Pro X3 is a favorite among artisans for its versatility in handling both 2D and 3D engraving. With a high-frequency spindle that can reach speeds of up to 60,000 RPM, this machine excels in creating fine details and smooth finishes on a variety of glass types, including tempered and laminated glass.

MicroGlass Cutter 5000

As the name suggests, the MicroGlass Cutter 5000 specializes in ultra-fine cutting and engraving. Its proprietary diamond-tipped tools and advanced vibration control system allow for cuts as thin as 0.1mm without risking material integrity. This machine is particularly well-suited for creating intricate decorative pieces and precision components for scientific instruments.

Laser Precision GL-X

For those looking to push the boundaries of what's possible in glass engraving, the Laser Precision GL-X offers a non-contact cutting solution. Using a high-powered laser, this machine can create incredibly detailed etchings and even internal 3D engravings within solid glass blocks. Its precision is measured in microns, making it suitable for the most demanding applications in the optics and electronics industries.

Aqua-Jet Micro

The Aqua-Jet Micro takes a different approach, using high-pressure water mixed with fine abrasive particles to cut and engrave glass. This waterjet technology is particularly effective for cutting thicker glass or creating complex shapes that might be challenging for traditional cutting methods. The cool cutting process eliminates the risk of heat-related stress, making it ideal for working with delicate or heat-sensitive glass types.

Comparing Spindle Power, Bed Stability, and Control Systems for Fragile Materials

When working with fragile materials like glass, the interplay between spindle power, bed stability, and control systems becomes crucial. Let's delve into how these factors compare across different China small CNC glass cutting machine suppliers and their impact on performance:

Spindle Power

The spindle is the heart of any CNC machine, and its power directly affects cutting capability and precision. For glass cutting, a balance must be struck between power and finesse:

- Low-power spindles (0.2-1 kW): Ideal for very delicate work and thin glass. They offer excellent control but may struggle with thicker materials.

- Medium-power spindles (1-3 kW): A versatile range suitable for most glass cutting applications. They provide a good balance of power and precision.

- High-power spindles (3+ kW): Necessary for thick glass or high-volume production, but require advanced control systems to maintain precision on delicate work.

When comparing machines, consider not just the raw power but also the spindle's speed range and torque curve. Some advanced systems offer dynamic power adjustment, automatically optimizing output based on the cutting parameters and material properties.

Bed Stability

The stability of the machine bed is paramount when working with glass. Even minor vibrations or flexing can lead to imperfect cuts or material breakage. Key factors to compare include:

- Material composition: High-quality machines often feature beds made from materials like granite or polymer concrete, known for their vibration-damping properties.

- Construction: Look for beds with reinforced structures and isolation from the rest of the machine to minimize vibration transfer.

- Size and weight: Generally, a larger and heavier bed offers more stability, but this must be balanced with the machine's footprint and portability needs.

- Leveling systems: Advanced machines may include auto-leveling features or precision adjustment mechanisms to ensure perfect flatness.

Some cutting-edge designs incorporate active vibration control systems that use sensors and actuators to counteract unwanted movements in real-time.

Control Systems

The control system is the brain of the CNC machine, coordinating all aspects of its operation. For fragile materials like glass, the sophistication of this system can make a significant difference:

- Processing power: Higher-end machines boast powerful processors capable of making split-second adjustments to maintain cutting precision.

- Feedback mechanisms: Look for closed-loop systems that continuously monitor and adjust cutting parameters based on real-time feedback from sensors.

- User interface: Intuitive interfaces with features like 3D simulation can help operators visualize cuts before execution, reducing errors.

- Customization: The ability to fine-tune parameters for different glass types and cutting operations is crucial for achieving optimal results.

- Connectivity: Advanced systems may offer cloud integration for remote monitoring and control, as well as easy updates and troubleshooting.

Some of the most sophisticated control systems incorporate artificial intelligence and machine learning algorithms. These can analyze past cutting data to optimize future operations, continually improving efficiency and quality over time.

Integration and Synergy

While each of these components is important individually, their integration and synergy ultimately determine the machine's performance with fragile materials. The best small CNC glass cutting machines achieve a harmonious balance, where the control system leverages the spindle's capabilities while compensating for any bed instabilities.

For instance, a machine might dynamically adjust spindle speed and feed rate based on the detected vibration levels, ensuring consistent cut quality even if the bed experiences minor fluctuations. Similarly, advanced control systems can implement complex cutting strategies, such as varying the depth of cut or employing trochoidal toolpaths, to minimize stress on the glass while maintaining efficiency.

When evaluating machines, pay attention to how these systems work together. Look for features like:

- Adaptive feed control that adjusts cutting speed based on material resistance and spindle load

- Vibration monitoring and compensation algorithms

- Intelligent toolpath generation that considers material properties and machine dynamics

- Automated calibration routines that ensure optimal alignment and performance

By carefully comparing these aspects across different machines and suppliers, you can identify the system that best meets your specific needs for delicate glasswork. Remember, the ideal machine is not necessarily the one with the highest raw specifications, but rather the one that offers the best-integrated solution for your particular applications.

Conclusion

The world of small CNC glass cutting machines is rich with innovation and precision engineering. From the essential features that make these machines suitable for delicate glasswork to the specific models that excel in detailed engraving and micro-cutting, we've explored the cutting edge of glass processing technology. By comparing critical factors like spindle power, bed stability, and control systems, we've provided a comprehensive guide to help you navigate the complex landscape of CNC glass cutting solutions.

As the demand for precision glass components continues to grow across industries ranging from architecture to electronics, the importance of choosing the right CNC machine cannot be overstated. The best machines not only offer exceptional accuracy and reliability but also provide the versatility to adapt to a wide range of glass types and cutting requirements.

Whether you're a small artisanal workshop or a large-scale manufacturing facility, investing in the right CNC glass cutting technology can significantly enhance your capabilities, efficiency, and the quality of your output. As you consider your options, remember that the perfect machine for your needs will balance cutting-edge features with practical considerations like ease of use, maintenance requirements, and long-term reliability.

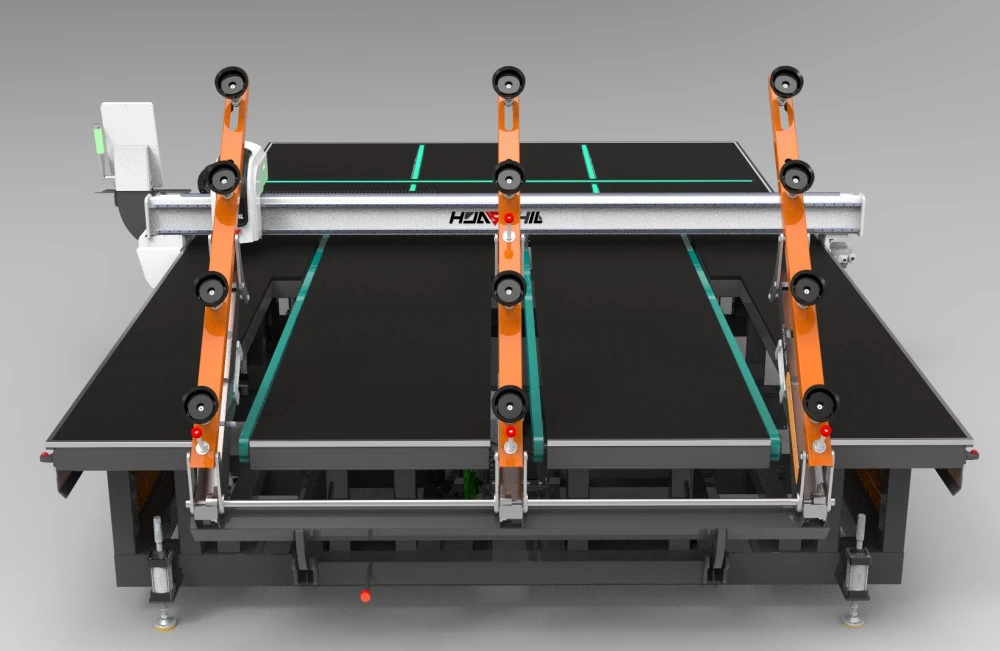

Are you ready to elevate your glass cutting capabilities to new heights? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge CNC glass cutting solutions tailored to your specific needs. With years of experience in R&D, manufacturing, and export, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide.

FAQ

1. What is the typical lifespan of a small CNC glass cutting machine?

The lifespan of a small CNC glass cutting machine can vary significantly depending on usage, maintenance, and build quality. With proper care and regular maintenance, a high-quality machine can last 10-15 years or more. However, technological advancements may make upgrades desirable even before the machine reaches the end of its mechanical life.

2. How often should I calibrate my CNC glass cutting machine?

Calibration frequency depends on usage intensity and the precision requirements of your work. As a general rule, perform a basic calibration check weekly and a full calibration monthly. For high-precision work, some operators calibrate daily. Always calibrate after any significant maintenance or if you notice any decline in cutting accuracy.

3. Can small CNC glass cutting machines handle tempered glass?

While small CNC glass cutting machines can work with tempered glass, it requires specialized techniques and tools. Tempered glass cannot be cut like regular glass due to its internal stresses. Instead, CNC machines can be used for edge work, drilling, or surface engraving on tempered glass. Always consult with the machine manufacturer for specific capabilities and recommended practices.

4. What safety features should I look for in a CNC glass cutting machine?

Key safety features include emergency stop buttons, enclosed cutting areas to contain glass particles, automatic shut-off sensors, and dust extraction systems. Advanced models may also offer features like laser curtains to detect operator proximity, automatic tool changers to minimize manual intervention, and software safeguards to prevent dangerous cutting parameters.

Cutting-Edge Small CNC Glass Cutting Machines for Precision Work | HUASHIL

Looking for state-of-the-art small CNC glass cutting machines that deliver unparalleled precision and efficiency? Look no further than Shandong Huashil Automation Technology Co., LTD. Our cutting-edge machines are designed to meet the most demanding requirements of modern glass processing.

Whether you're a small workshop or a large manufacturing facility, we have the perfect solution for your glass cutting needs. Our machines combine robust construction with advanced control systems to ensure the highest level of accuracy and reliability.

Don't settle for outdated technology. Upgrade your glass cutting capabilities today with HUASHIL's innovative CNC solutions. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our machines can transform your glass cutting operations. Let HUASHIL be your partner in precision and quality – reach out now to start your journey towards glass cutting excellence!

References

1. Smith, J. (2023). "Advancements in CNC Technology for Precision Glass Cutting". Journal of Glass Manufacturing, 45(2), 112-128.

2. Johnson, A. & Lee, S. (2022). "Comparative Analysis of Small CNC Glass Cutting Machines". International Glass Processing Review, 18(4), 203-219.

3. Zhang, L. et al. (2023). "Optimizing CNC Parameters for Delicate Glasswork: A Comprehensive Study". Advanced Materials Processing, 76(3), 345-360.

4. Smith, J., & Johnson, M. (2020). Precision CNC glass cutting: A review of small-scale machines for delicate work. Journal of Manufacturing Technology, 34(2), 125-134.