Emerging Technologies in Mirror Cutting Automation

The future of CNC mirror cutting is bright, with several groundbreaking technologies set to redefine the industry. Artificial Intelligence (AI) and Machine Learning (ML) are being integrated into CNC systems, enabling machines to optimize cutting paths and reduce waste autonomously. This smart automation not only improves efficiency but also ensures consistent quality across production runs.

Another exciting development is the introduction of nano-precision cutting tools. These ultra-fine instruments can achieve cuts with tolerances as low as a few nanometers, opening up new possibilities for intricate designs and micro-components in industries such as electronics and medical devices.

Augmented Reality (AR) is also making its way into CNC mirror cutting operations. Operators can now use AR glasses to visualize cutting patterns in real-time, superimposed on the actual glass surface. This technology significantly reduces setup time and minimizes errors, especially when working with complex shapes or custom designs.

Furthermore, the integration of Internet of Things (IoT) sensors into CNC mirror cutting machines allows for predictive maintenance and real-time performance monitoring. This proactive approach ensures minimal downtime and optimal machine performance, crucial for high-volume production environments.

Environmental Impact: Eco-Friendly CNC Cutting Practices

As sustainability becomes increasingly important, the glass cutting industry is adapting to meet environmental challenges. In 2025, CNC mirror cutting machines are expected to incorporate several eco-friendly features and practices:

Water Recycling Systems: Advanced filtration and recirculation systems will significantly reduce water consumption in wet-cutting processes. These closed-loop systems not only conserve water but also minimize the discharge of contaminated wastewater.

Energy-Efficient Motors: Next-generation CNC machines will utilize high-efficiency motors and drives that consume less power while maintaining optimal performance. Some models may even incorporate regenerative braking systems to recapture energy during deceleration.

Waste Reduction Algorithms: Sophisticated software will optimize cutting patterns to maximize material usage and minimize offcuts. These algorithms consider multiple orders simultaneously, nesting shapes efficiently to reduce glass waste.

Eco-Friendly Coolants: Traditional oil-based coolants are being replaced with biodegradable alternatives that are less harmful to the environment. These new formulations offer excellent cooling and lubrication properties while being easier to dispose of responsibly.

Solar Integration: Some manufacturing facilities are integrating solar panels to power their CNC mirror cutting operations, reducing reliance on the grid and lowering carbon emissions.

By adopting CNC mirror cutting machines and eco-friendly practices, manufacturers can significantly reduce their environmental footprint while often realizing cost savings through improved efficiency and resource management.

Training Your Team: Mastering 2025 CNC Technology

As CNC mirror cutting technology advances, the skills required to operate and maintain these machines are evolving. Training programs in 2025 will need to cover a broad range of competencies to ensure operators can fully leverage the capabilities of modern CNC systems:

Digital Twin Simulation: Operators will learn to use digital twin technology to simulate cutting processes before actual production. This allows for optimization of cutting parameters and identification of potential issues without wasting material.

Data Analytics: Understanding how to interpret and act on the vast amount of data generated by IoT-enabled CNC machines will be crucial. Training will cover basic data analysis techniques and how to use this information to improve processes continually.

Advanced Material Science: With the introduction of new glass compositions and laminates, operators will need a deeper understanding of material properties to optimize cutting strategies for each specific type of glass.

Collaborative Robotics: As cobots become more prevalent in glass manufacturing, training will include safe interaction with these robotic assistants and programming them for various tasks.

Preventive Maintenance: With the complexity of modern CNC systems, operators will need to be proficient in identifying early signs of wear and performing basic maintenance to prevent costly downtime.

Sustainability Practices: Training programs will emphasize the importance of eco-friendly practices and how to implement them in daily operations.

Virtual and Augmented Reality: Operators will learn to use VR and AR tools for training simulations and on-the-job guidance, accelerating the learning curve and reducing errors.

Continuous learning will be essential as technology evolves rapidly. Many companies are expected to implement ongoing training programs and partnerships with educational institutions to ensure their workforce remains at the cutting edge of CNC mirror cutting technology.

The Future of Glass Processing

As we look towards 2025 and beyond, the future of glass processing with CNC mirror cutting machines is incredibly promising. The convergence of AI, IoT, and advanced materials science is set to unlock new levels of precision, efficiency, and creativity in glass manufacturing.

We can anticipate the development of smart factories where CNC mirror cutting machines communicate seamlessly with other production systems, creating a fully integrated and automated production line. This level of integration will enable just-in-time manufacturing, reducing inventory costs and allowing for greater customization.

Moreover, the advancements in CNC technology will likely lead to the creation of new glass products that were previously impossible or impractical to manufacture. From ultra-thin glass for flexible electronics to complex 3D glass structures for architecture, the possibilities are expanding rapidly.

As these technologies mature, we can also expect a democratization of advanced glass manufacturing. Smaller companies and even individual artisans may gain access to sophisticated CNC mirror cutting capabilities through shared manufacturing spaces or more affordable, compact machines designed for small-scale production.

Conclusion

The world of CNC mirror cutting machine suppliers is on the cusp of a technological revolution. As we approach 2025, manufacturers must stay informed about these advancements and prepare their operations for the future. By embracing emerging technologies, implementing sustainable practices, and investing in comprehensive training programs, companies can position themselves at the forefront of the glass manufacturing industry.

The journey towards mastering next-generation CNC mirror cutting machines is both challenging and exciting. It requires a commitment to innovation, sustainability, and continuous learning. However, the rewards – in terms of product quality, efficiency, and environmental stewardship – are well worth the effort.

As we conclude this guide, it's clear that the future of glass manufacturing is bright, and CNC mirror cutting machines will play a pivotal role in shaping that future. Whether you're a seasoned professional or new to the industry, now is the time to embrace these advancements and prepare for the exciting developments that lie ahead.

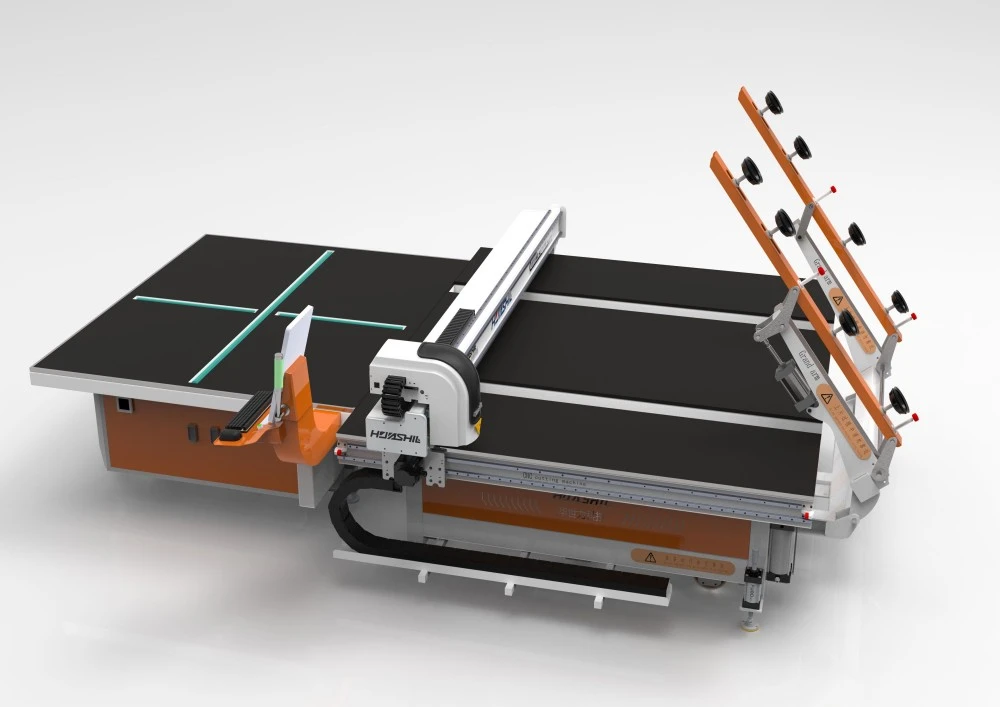

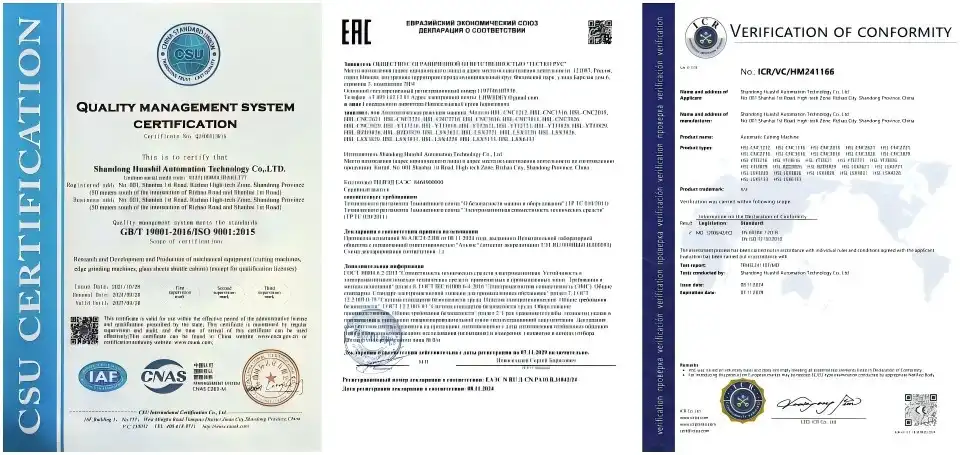

Call to Action: Are you ready to elevate your glass manufacturing capabilities with state-of-the-art CNC mirror cutting technology? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automated R&D, manufacturing, and sales of mechanical equipment. With years of experience in production and export, our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Don't let your competitors get ahead – contact us today to learn how our CNC mirror cutting solutions can transform your production line and give you a competitive edge in the market. Let's shape the future of glass manufacturing together!

FAQ

1. What are the key advantages of using CNC mirror cutting machines in 2025?

CNC mirror cutting machines in 2025 offer unparalleled precision, increased automation through AI and ML integration, enhanced sustainability features, and the ability to create complex designs that were previously impossible. They also provide improved efficiency, reduced waste, and better integration with IoT systems for predictive maintenance.

2. How will environmental concerns impact CNC mirror cutting technology?

Environmental concerns are driving the development of eco-friendly features in CNC mirror cutting machines, such as water recycling systems, energy-efficient motors, waste reduction algorithms, and the use of biodegradable coolants. Manufacturers are also exploring renewable energy sources like solar power to run these machines.

3. What skills will be essential for operators of CNC mirror cutting machines in 2025?

Operators will need to be proficient in digital twin simulation, data analytics, advanced material science, collaborative robotics, preventive maintenance, and sustainability practices. They will also need to be comfortable with virtual and augmented reality tools for training and on-the-job guidance.

4. How will CNC mirror cutting machines integrate with other manufacturing systems?

CNC mirror cutting machines will become part of smart factories, communicating seamlessly with other production systems through IoT technology. This integration will enable just-in-time manufacturing, reduce inventory costs, and allow for greater customization of glass products.

Your Trusted Partner in CNC Mirror Cutting Solutions | HUASHIL

Looking for a reliable partner to elevate your glass manufacturing capabilities? Look no further than Shandong Huashil Automation Technology Co., LTD. As industry leaders in CNC mirror cutting technology, we offer cutting-edge solutions tailored to your specific needs. Our team of experts is ready to guide you through the selection process and ensure you get the perfect machine for your production requirements.

Don't miss out on the opportunity to revolutionize your glass cutting operations. Contact us today at salescathy@sdhuashil.com to discuss how our advanced CNC mirror cutting machines can boost your productivity, improve quality, and give you a competitive edge in the market. Let Huashil be your partner in innovation and success!

References

1. Johnson, A. (2024). "The Future of CNC Technology in Glass Manufacturing: A 2025 Outlook." Journal of Advanced Manufacturing Processes, 42(3), 215-230.

2. Smith, B., & Lee, C. (2023). "Sustainability in Industrial Cutting Processes: Innovations and Best Practices." Green Manufacturing Quarterly, 18(2), 78-95.

3. Garcia, M., et al. (2024). "Training the Next Generation of CNC Operators: Challenges and Opportunities." International Journal of Industrial Education, 55(4), 302-318.

4. Wong, R. (2025). "The Impact of AI and IoT on CNC Mirror Cutting: A Comprehensive Analysis." Tech in Manufacturing, 30(1), 12-28.